Preparation method of potato raw flour noodle

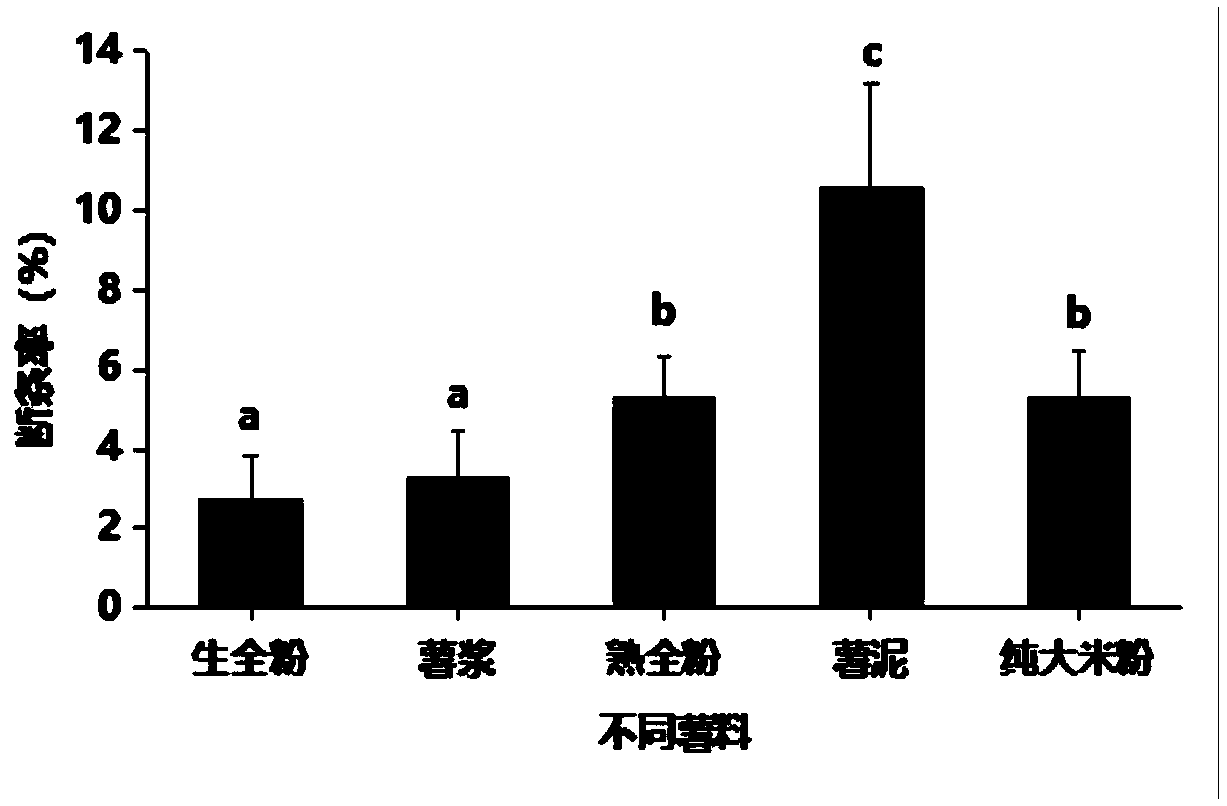

A raw potato powder and potato technology, which is applied in food science and other fields, can solve the problems of high water solubility of starch, and achieve the effects of long storage time, low bar breakage rate and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Selecting fresh potatoes, washing, peeling, slicing and color protection, drying at a temperature lower than 55°C, then grinding and sieving to obtain raw potato powder with a particle size of 100-120 mesh;

[0066] (2) Pour the raw potato powder prepared in step (1) into a mixer, and add rice flour with a particle size of 100 to 120 mesh, so that the rice flour accounts for 45% of the total mass of the mixed powder, and stir until uniform;

[0067] (3) Add drinking water with 40% of the total mass of the powder to the uniformly mixed powder, stir until uniform, and let stand for 20 minutes;

[0068] (4) Use a rice noodle machine with a hole diameter of 0.8 mm, preheat the rice noodle machine so that the temperature of the powder channel and extruding screw reaches the gelatinization temperature of the powder, turn on the rice noodle machine, and start feeding into the hopper, The feeding speed is set at 60r / min. When the powder fills the extruding channel, stop the...

Embodiment 2

[0070] (1) Selecting fresh potatoes, washing, peeling, slicing and color protection, drying at a temperature lower than 55°C, then grinding and sieving to obtain raw potato powder with a particle size of 100-120 mesh;

[0071] (2) Pour the raw potato powder prepared in step (1) into a mixer, and add rice flour with a particle size of 100 to 120 mesh, so that the rice flour accounts for 48% of the total mass of the mixed powder, and stir until uniform;

[0072] (3) Add drinking water with 38% of the total mass of the powder to the uniformly mixed powder, stir until uniform, and let stand for 20 minutes;

[0073] (4) Use a rice noodle machine with a hole diameter of 1.2mm, preheat the rice noodle machine so that the temperature of the powder channel and extruding screw reaches the gelatinization temperature of the powder, turn on the rice noodle machine, and start feeding into the hopper, The feeding speed is set at 50r / min. When the powder fills the extruding channel, stop the ...

Embodiment 3

[0075] (1) Selecting fresh potatoes, washing, peeling, slicing and color protection, drying at a temperature lower than 55°C, then grinding and sieving to obtain raw potato powder with a particle size of 100-120 mesh;

[0076] (2) Pour the raw potato powder prepared in step (1) into a mixer, and add rice flour with a particle size of 100 to 120 meshes, so that the rice flour accounts for 36% of the total mass of the mixed powder, and stir until uniform;

[0077] (3) Add drinking water with 42% of the total mass of the powder to the uniformly mixed powder, stir until uniform, and let stand for 20 minutes;

[0078] (4) Use a rice noodle machine with a hole diameter of 1.0 mm, preheat the rice noodle machine so that the temperature of the powder channel and extruding screw reaches the gelatinization temperature of the powder, turn on the rice noodle machine, and start feeding into the hopper, The feeding speed is set at 70r / min. When the powder is full of the extruding channel, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com