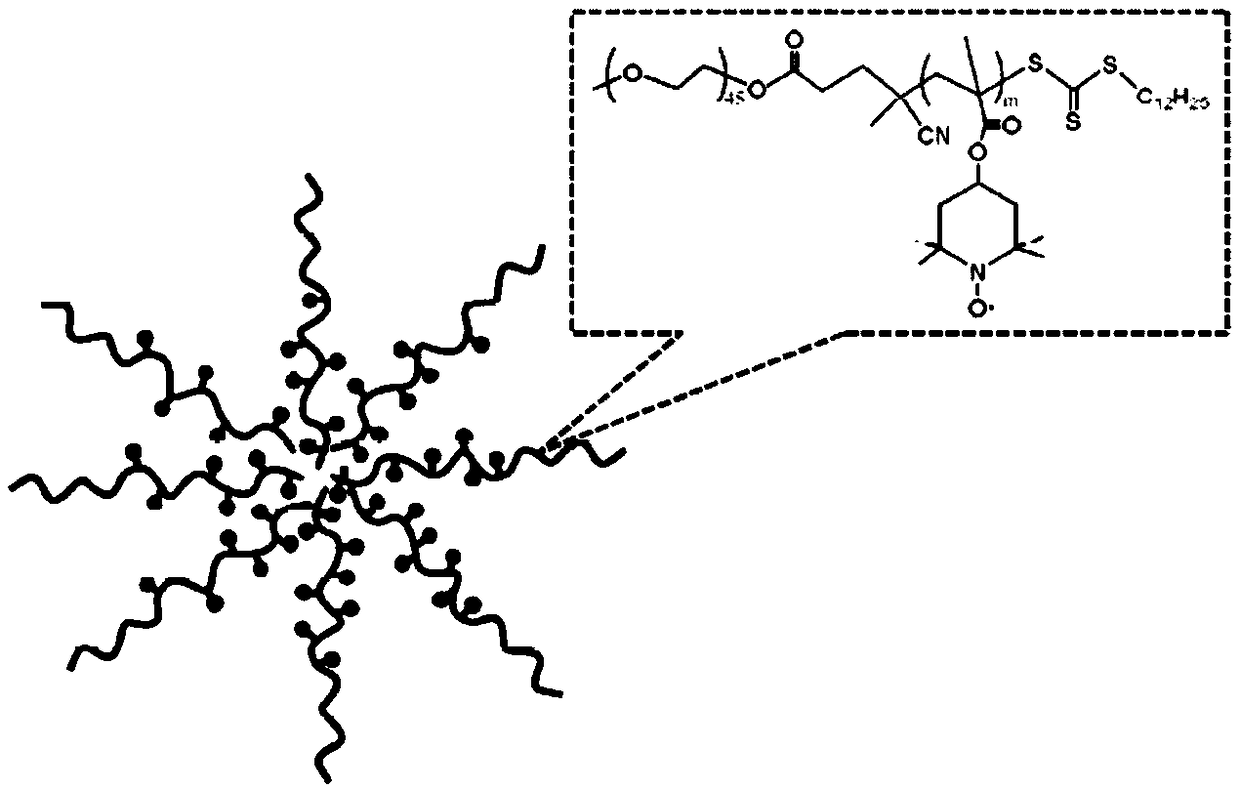

Oxidation-reduction stimulus response type nanometer medicine carrier as well as preparation method and application thereof

A nano-drug carrier and stimuli-response technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, emulsion delivery, etc., to achieve the effect of good application value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

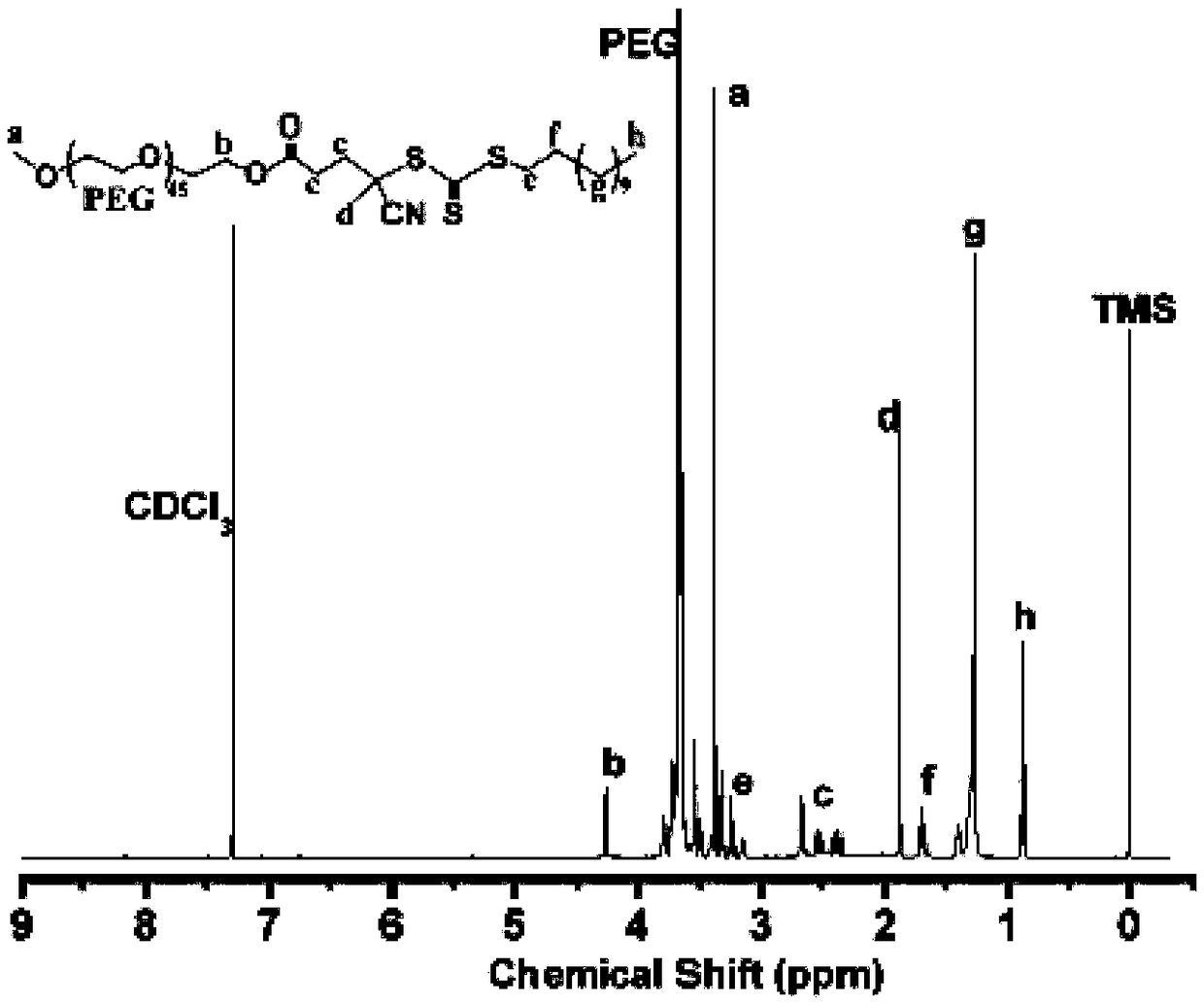

[0037] Embodiment 1: Preparation of mPEG-CDP(IV)

[0038] mPEG(II)(M n =2000, 2.00g, 1mmol), CDP(III) (0.80g, 2mmol), DMAP (0.12g, 1mmol), were added in 100ml dichloromethane; EDC (0.40g, 2mmol) was dissolved in 30mL dichloromethane Add it dropwise to the above system in an ice-bath environment, and react at room temperature for 18 hours. After the reaction is completed, evaporate part of the solvent, add the remaining liquid dropwise to cold ether to wash the precipitate, and repeat the washing for 3 After three times, the precipitate was put into a vacuum drying oven at 40° C. overnight to obtain 2.11 g of the macromolecular RAFT reagent mPEG-CDP(IV), with a yield of 87%.

Embodiment 2

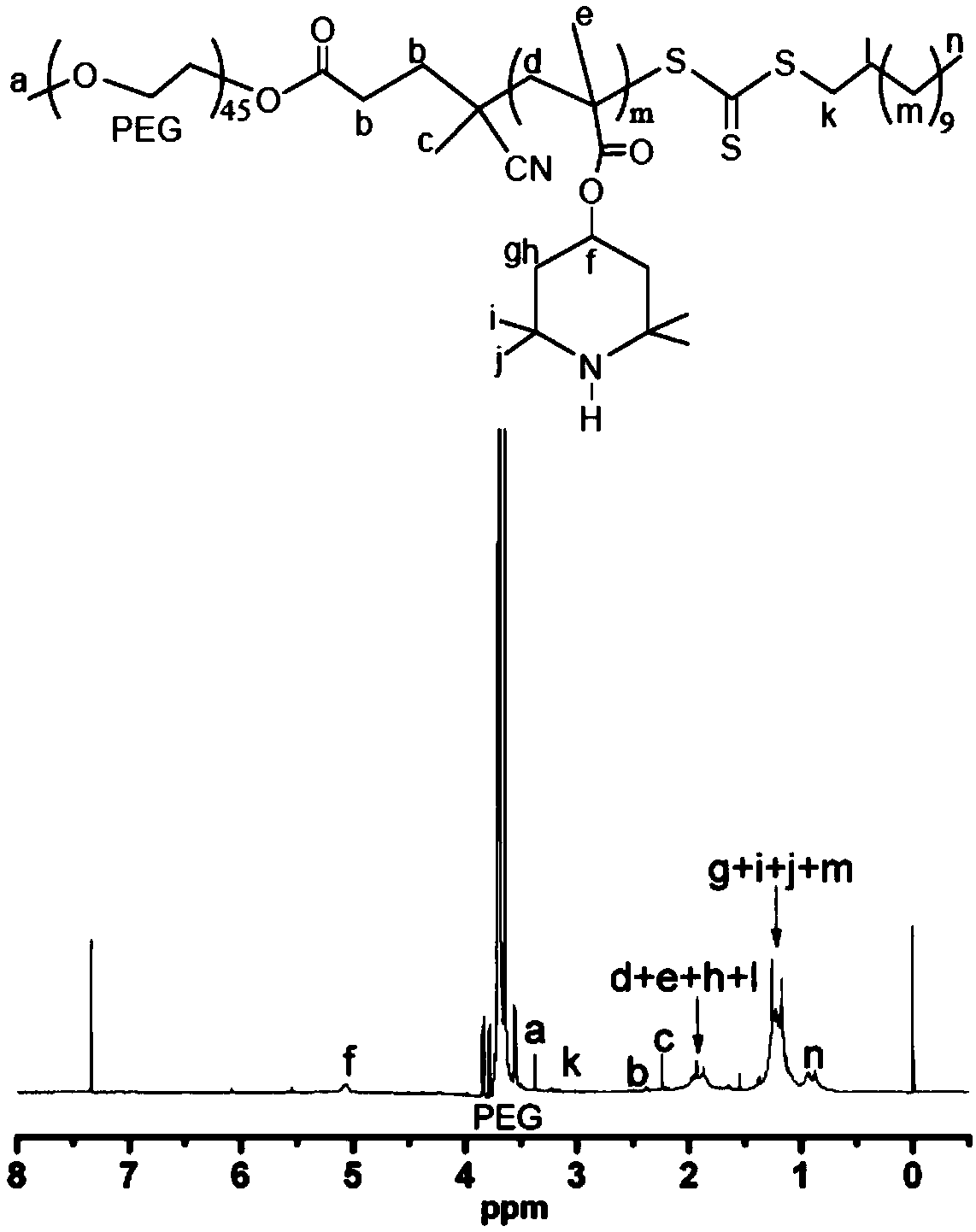

[0039] Embodiment 2: Preparation of PEG-b-PTMPM (V)

[0040] Add mPEG-CDP(IV) (0.48g, 0.2mmol), AIBN (11mg, 0.067mmol), TMPM (0.90g, 4mmol) and 5.5mL of dioxane into a 50mL single-necked round bottom flask respectively. Pass N 2 After 30 minutes, react at 70°C for 24h, precipitate the liquid obtained by the reaction with petroleum ether, put the precipitate in a vacuum drying oven, and dry overnight at 40°C to obtain 1.31g of polymer PEG-b-PTMPM(V). 95%.

Embodiment 3

[0041] Embodiment 3: Preparation of PEG-b-PTMA (VI)

[0042] Add polymer PEG-b-PTMPM (V) (1.0 g, containing 2.92 mmol of secondary amine groups), Na 2 WO 4 2H 2 O (0.24g, 0.73mmol), EDTA (0.12g, 0.41mmol), THF 5mL, stirred at room temperature for 30min, then transferred to 60°C oil bath, slowly added H 2 o 2 3.0 mL, reacted for 24 hours, precipitated the liquid obtained by the reaction with petroleum ether, put the precipitate in a vacuum drying oven, and dried overnight at 40°C to obtain 0.82 g of polymer PEG-b-PTMA(VI), with a yield of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com