Preparation method of novel antibacterial agent

An antibacterial agent, a certain amount of technology, applied in the field of preparation of new antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The application provides a preparation method of an antibacterial agent, comprising the following steps:

[0022] (1) Weigh a certain amount of diyttrium trioxide, deionized water, and nitric acid, add them to the reaction vessel, and react at 40-60°C for 3-5h to form Y(NO3) 3 ·6H 2 O; the mass ratio of diyttrium trioxide, deionized water, and nitric acid is (20-30): (120-160): (50-70).

[0023] (2) Weigh a certain amount of nonylphenol polyoxyethylene ether, glycerol, cycloheptane, Y(NO3) 3 ·6H 2 O, add them to the reaction vessel, stir and react at room temperature for 2-4h to form solution A; nonylphenol polyoxyethylene ether, glycerol, cycloheptane, Y(NO3) 3 ·6H 2 The mass ratio of O is (3-7):(8-10):(30-50):(80-100).

[0024] (3) Weigh a certain amount of nonylphenol polyoxyethylene ether, glycerol, cycloheptane, 5-chloro-7-hydroxyquinoline, and sodium o-hydroxyphenylacetate, and add them to the reaction vessel. Under stirring reaction 1-3h, form solution B; T...

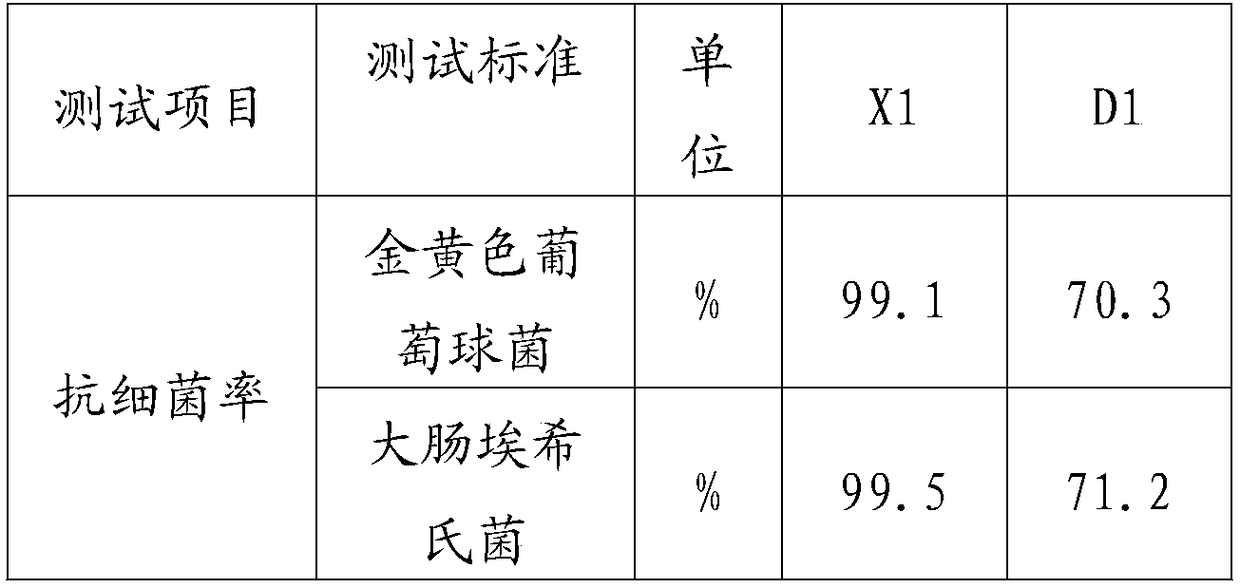

Embodiment 1

[0028] (1) Weigh 200g of diyttrium trioxide, 1.2kg of deionized water, and 500g of nitric acid, add them to the reaction vessel, and react at 40°C for 3 hours to form Y(NO3) 3 ·6H 2 O.

[0029] (2) Weigh 30g nonylphenol polyoxyethylene ether, 80g glycerin, 300g cycloheptane, 800gY(NO3) 3 ·6H 2 O, they were added to the reaction vessel, stirred and reacted at room temperature for 2h to form solution A.

[0030] (3) Weigh 40g nonylphenol polyoxyethylene ether, 60g glycerol, 200g cycloheptane, 10g5-chloro-7-hydroxyquinoline, 500g sodium o-hydroxyphenylacetate, add them to the reaction vessel, and The reaction was stirred at room temperature for 1 h to form solution B.

[0031] (4) Weigh 400g of solution A, 300g of solution B, and 100g of tetraethyl orthosilicate, add them to the reaction vessel, stir and react at room temperature for 3h, centrifuge with a centrifuge, draw the clear liquid, and then use Wash with ethanol and distilled water, centrifuge twice, place in an oven...

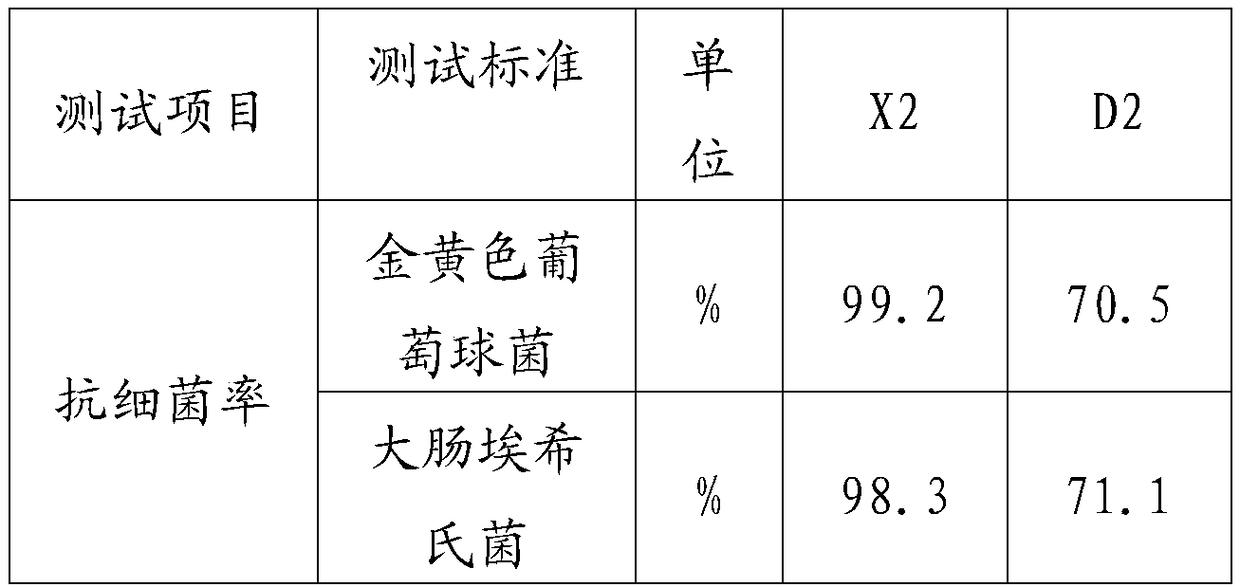

Embodiment 2

[0041] (1) Weigh 300g of diyttrium trioxide, 1.6kg of deionized water, and 700g of nitric acid, add them to the reaction vessel, and react at 60°C for 5h to form Y(NO3) 3 ·6H 2 O.

[0042] (2) Weigh 70g nonylphenol polyoxyethylene ether, 100g glycerol, 500g cycloheptane, 1.0kgY(NO3) 3 ·6H 2 O, they were added to the reaction vessel, stirred and reacted at room temperature for 4h to form solution A.

[0043] (3) Weigh 60g nonylphenol polyoxyethylene ether, 100g glycerol, 300g cycloheptane, 30g 5-chloro-7-hydroxyquinoline, 700g sodium o-hydroxyphenylacetate, add them to the reaction vessel, and The reaction was stirred at room temperature for 3 h to form solution B.

[0044] (4) Weigh 600g of solution A, 500g of solution B, and 200g of tetraethylorthosilicate, add them to the reaction vessel, stir and react at room temperature for 5h, centrifuge with a centrifuge, draw the clear liquid, and use Wash with ethanol and deionized water, centrifuge twice, put in an oven at 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com