A kind of method for electrodepositing rhenium metal

A technology of electrodeposition and metal, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of cumbersome process, single method, low efficiency, etc., and achieve the effect of simple process, simplified process flow and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

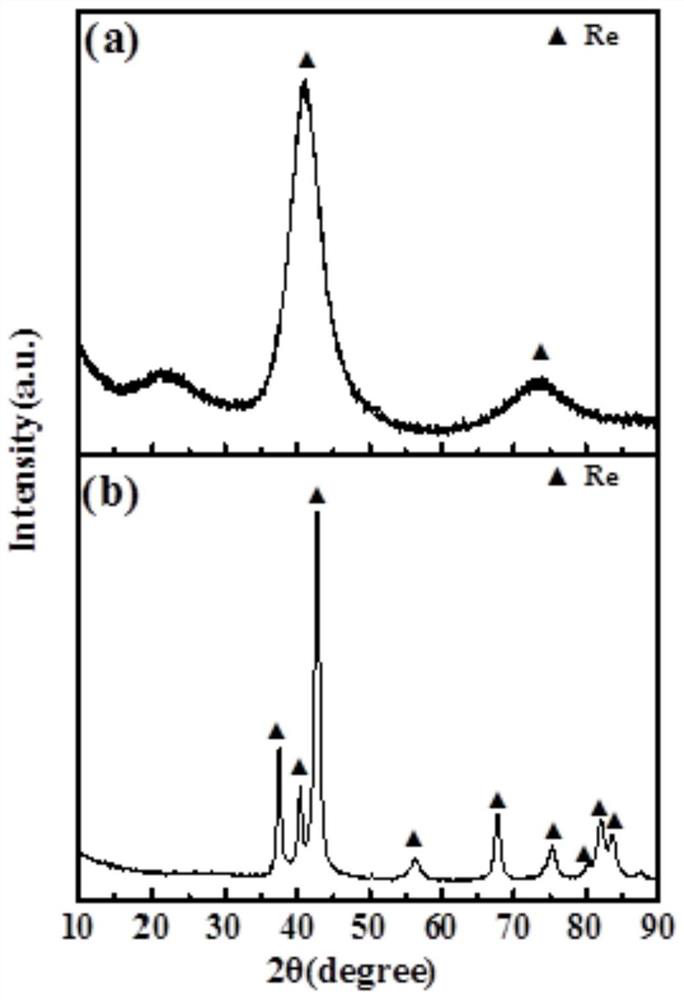

Image

Examples

Embodiment 1

[0044] A method for electrodepositing metal rhenium, said method comprising the following steps:

[0045] 1) Choose a 1cm×1cm copper sheet as the metal workpiece, and use 400#, 600# and 800# sandpaper to polish the metal workpiece until the surface is smooth, then use alumina polishing agent to polish the metal workpiece, and wash it with water after polishing , placed in an ethanol solution for ultrasonic vibration for 5 minutes, then washed with water and dried at 40°C to obtain a bright metal workpiece;

[0046]2) Place the bright metal workpiece obtained by step 1) in the electrolyte, use the metal workpiece as the cathode, and use the platinum electrode as the anode to conduct electrodeposition. The electrodeposition is carried out at 60°C, and the current density is controlled at 15mA / cm 2 , the electrodeposition time is 5h, and a rhenium metal layer is obtained on the surface of the metal workpiece after the electrodeposition is completed;

[0047] Wherein, in the el...

Embodiment 2

[0049] A method for electrodepositing metal rhenium, said method comprising the following steps:

[0050] 1) Select a 6cm×8cm copper sheet as the metal workpiece, and use 400#, 600# and 800# sandpaper to polish the metal workpiece until the surface is smooth, then use alumina polishing agent to polish the metal workpiece, and wash it with water after polishing , placed in an ethanol solution for ultrasonic vibration for 15 minutes, then washed with water and then dried at 60°C to obtain a bright metal workpiece;

[0051] 2) Place the bright metal workpiece obtained through step 1) in the electrolyte, use the metal workpiece as the cathode, and use the ruthenium-titanium electrode as the anode to conduct electrodeposition. The electrodeposition is carried out at 70° C., and the current density is controlled to be 15mA / cm 2 , the electrodeposition time is 6h, and a rhenium metal layer is obtained on the surface of the metal workpiece after the electrodeposition is completed;

...

Embodiment 3

[0054] A method for electrodepositing metal rhenium, said method comprising the following steps:

[0055] 1) Select a 6cm×8cm nickel sheet as the metal workpiece, and use 400#, 600# and 800# sandpaper to polish the metal workpiece until the surface is smooth, then use alumina polishing agent to polish the metal workpiece, and wash it with water after polishing , placed in an ethanol solution for ultrasonic vibration for 10 minutes, then washed with water and dried at 60°C to obtain a bright metal workpiece;

[0056] 2) Place the bright metal workpiece obtained by step 1) in the electrolyte, use the metal workpiece as the cathode, and use the graphite electrode as the anode to conduct electrodeposition. The electrodeposition is carried out at 70°C, and the current density is controlled at 15mA / cm 2 , the electrodeposition time is 10h, and a rhenium metal layer is obtained on the surface of the metal workpiece after the electrodeposition is completed;

[0057] Wherein, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com