A marine climate environment-torsional load coupling test device and test method

A technology of torsional load and marine climate, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problem that the torsion test device cannot work for a long time and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

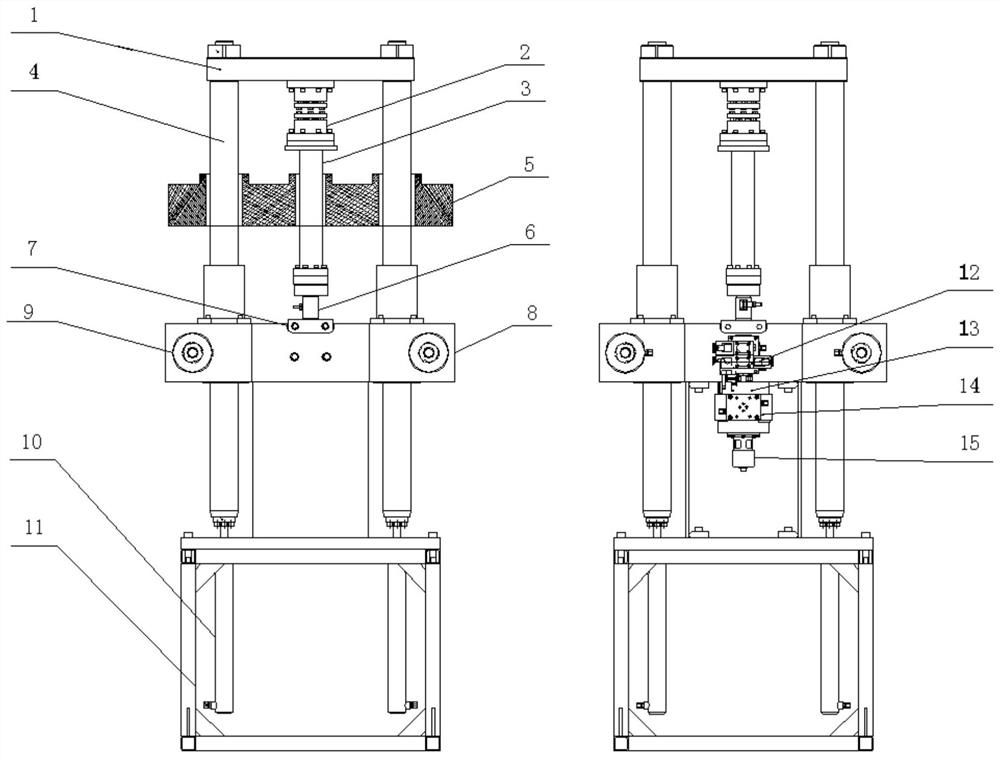

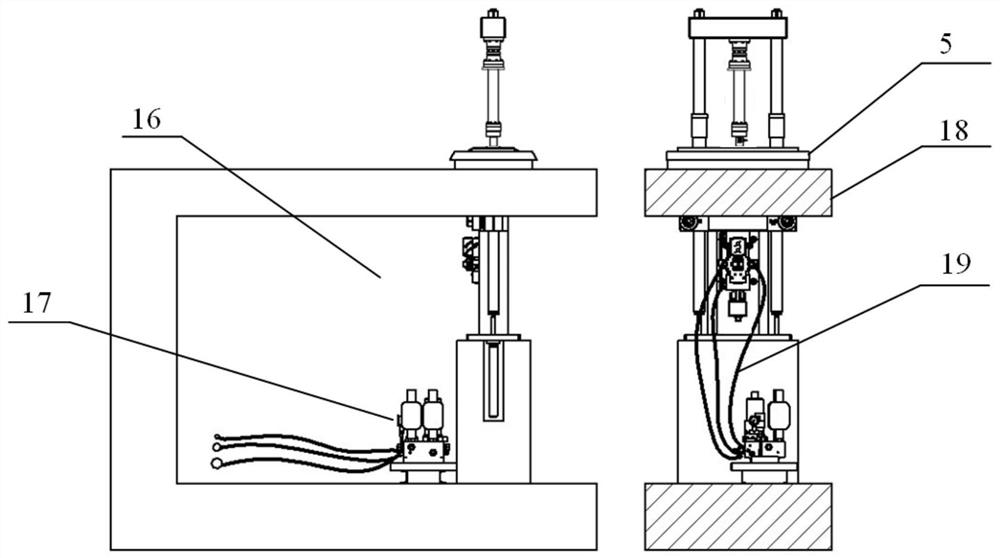

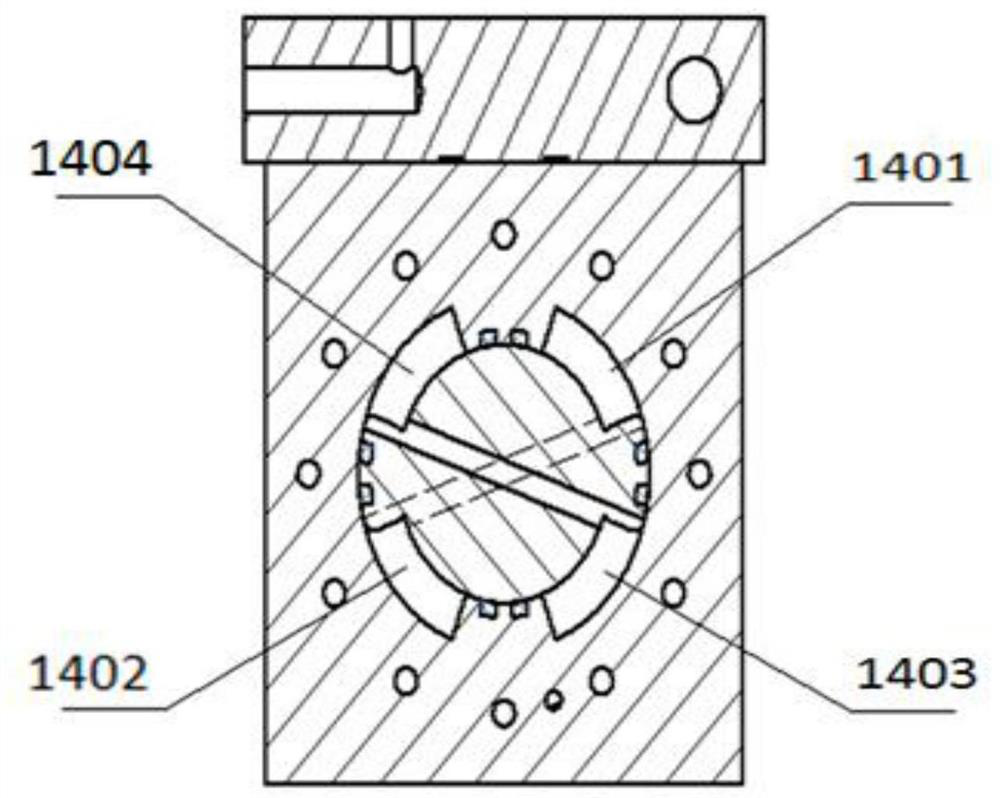

[0034] A marine climate environment-torsional load coupling test device, such as figure 1 and figure 2As shown, a vertical layout is adopted, including a frame structure. A clamping mechanism 2 is arranged on the upper part of the frame structure. The clamping mechanism 2 is connected to a servo torsional fatigue system, and the servo torsional fatigue system is connected to a signal detection unit. The signal detection unit includes a The torque sensor 6 for detecting torque and the angle sensor 15 for detecting the torsion angle, the servo torsional fatigue system is connected to the hydraulic power system 17 and drives the servo torsional fatigue system to run through the hydraulic power system 17, and the servo torsional fatigue system is connected to the environmental test control system (this The environmental test control system of the invention refers to a conventional software control system capable of setting test conditions such as test loading cycle and loading fo...

Embodiment 2

[0053] A kind of marine climate environment-torsional load coupling test method, this test method adopts the test device in embodiment 1 to carry out static torsion test, and its steps include:

[0054] Step 1, open the environmental test control system, start the hydraulic power system of the marine climate environment-torsional load coupling test device;

[0055] Step 2: Drive the column and the beam to move upwards. When the clamping distance of the sample is greater than the total length of the sample, install one end of the sample on the upper chuck, then move the column and the moving beam down to a suitable position, and place the other end of the sample Installed on the lower chuck, lock the locking cylinder on both sides of the workbench to complete the sample installation;

[0056] Step 3. After the installation of the sample is completed, determine the torsion test condition according to the torsional load of the product corresponding to the sample in service, set t...

Embodiment 3

[0058] A marine climate environment-torsional load coupling test method, the test method adopts the test device in embodiment 1 to carry out dynamic torsion test on a 30CrMnSiNi2A high-strength steel sample whose size is Φ10×200mm, and the steps include:

[0059] Step 1, open the environmental test control system, start the hydraulic power system of the marine climate environment-torsional load coupling test device;

[0060] Step 2: Drive the column and the beam to move upwards. When the clamping distance of the sample is greater than the total length of the sample, install one end of the sample on the upper chuck, then move the column and the moving beam down to a suitable position, and place the other end of the sample Installed on the lower chuck, lock the locking cylinder on both sides of the workbench to complete the sample installation;

[0061] Step 3: After the installation of the sample is completed, determine the torsion test conditions according to the torsional loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com