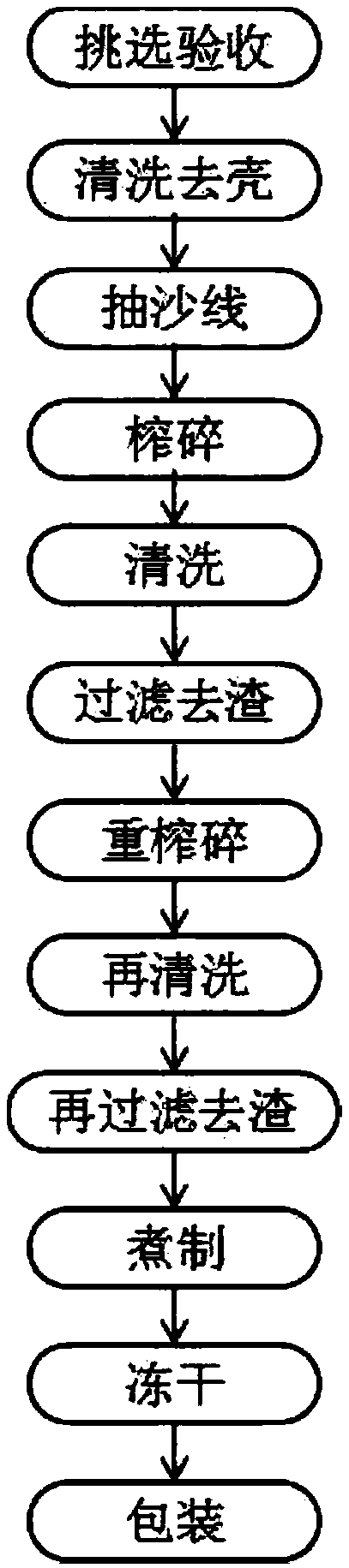

Manufacturing process of instant prawn tofu

A production process and tofu technology, applied in food science and other directions, can solve the problems of complex preparation and eating process, inconvenience for the elderly and children to eat, increase time cost, etc., and achieve the effect of increasing time cost, soft meat, and promoting growth and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of preparation technology one of instant shrimp tofu

[0034] The invention provides a production process of instant shrimp tofu, which uses fresh and live seawater monodon prawns as raw materials, undergoes selection, cleaning, shelling, extraction of shrimp threads, crushing, cleaning, filtering to remove slag, re-cleaning, and re-processing. It is a delicious food made by crushing, filtering to remove slag, extracting soup, and cooking with special technology. The method steps are as follows:

[0035] (1) Acceptance selection: strictly control the purchase of raw materials. Pick up new raw materials in a timely manner, and select an appropriate amount of seawater prawns that are fresh, intact, fat, tight, bright in color, shiny, and free from whitish or blackening; strictly remove dead shrimp, shrimp shells and all Impurities are then placed in the cleaning pool.

[0036](2) Cleaning: Put the fresh and live tiger prawns after acceptance and se...

Embodiment 2

[0044] Embodiment 2: A kind of preparation process two of instant shrimp tofu

[0045] In order to peel off the remaining shrimp meat in the shrimp shell to the greatest extent, based on embodiment 1, the embodiment adds the following steps between (7) filtering to remove slag and (8) getting the soup:

[0046] (1) Squeezing and crushing: Put the taken out broken shells of the tiger prawns into a grinder and crush them into a paste.

[0047] (2) Re-cleaning: add a small amount of water to the shell and meat of the prawn and then clean it.

[0048] (3) Re-filter to remove dregs: Pass the crushed dregs together with the soup through a 100-mesh sieve or filter cloth, squeeze and filter to remove the dregs, and keep the soup for later use; throw away the broken shells of the prawns.

Embodiment 3

[0049] Example 3: Shrimp tofu sold and eaten on site

[0050] Based on Example 1 and Example 2, after the shrimp tofu is successfully prepared, an appropriate amount of salt, monosodium glutamate, cooking wine, and chopped green onion can be directly added. Boil the pot and add the seasoning, put it into the prepared soup bowl, put the 7-9mm long chives in advance, and make the fresh, delicious and mouth-watering spotted shrimp hibiscus tofu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com