Sulfonate-type fluorosilicone anionic surfactant and preparation method thereof

A surfactant and sulfonate-type technology, which is applied in the field of sulfonate-type fluorosilicon anionic surfactant and its preparation, can solve environmental and human health hazards, perfluorooctane sulfonic acid difficult hydrolysis, photolysis or Microbial degradation and other problems, to achieve the effect of expanding the application range, good water solubility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

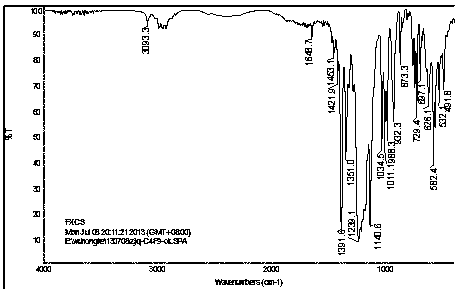

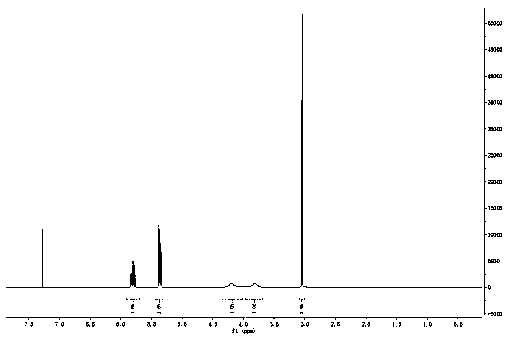

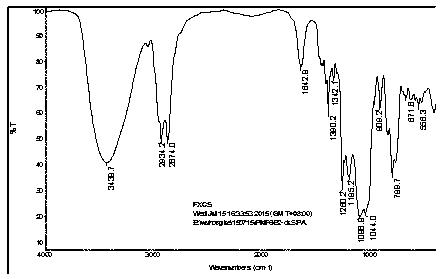

[0029] A kind of preparation method of sulfonate type fluorosilicon anionic surfactant, such as Figure 1-4 Shown, this preparation method comprises the following steps:

[0030] (1) Add 20mL of ethyl acetate and 1.78g of N-methallylamine to a 50mL four-necked flask equipped with a stirrer, thermometer, dropping funnel and reflux condenser, which is equipped with anhydrous CaCl 2 Drying tube, the concentration of the 1.78g N-methylallylamine is 0.025mol, gradually drop 4.02g perfluorohexylsulfonyl fluoride at room temperature, the concentration of the 4.02g perfluorohexylsulfonyl fluoride is 0.01mol, control After 30 minutes of dropwise addition, continue to stir and react at 40°C for 2 hours; after stopping the reaction, pour the reaction solution into 100mL water, remove the lower layer of light yellow liquid after layering, and successively wash with 50mL 5% HCl aqueous solution, 30mL saturated NaCO 3 Wash with aqueous solution and 2×30mL water, and dry over anhydrous sodi...

Embodiment 1

[0036] A kind of preparation method based on sulfonate type fluorosilicon anionic surfactant of the present embodiment comprises the following steps:

[0037] (1) Synthesis of NSF6

[0038] Equipped with a stirrer, thermometer, dropping funnel and reflux condenser (anhydrous CaCl 2 Add 20mL of ethyl acetate and 1.78g (0.025mol) of N-methallylamine into a 50mL four-necked flask, and gradually add 4.02g (0.01mol) of perfluorohexylsulfonyl fluoride dropwise at room temperature for about 30min. After the addition was complete, the stirring reaction was continued at 40°C for 2h. After stopping the reaction, pour the reaction solution into 100mL water, remove the light yellow liquid in the lower layer after layering, and wash with 50mL 5% HCl aqueous solution, 30mL saturated NaCO 3 Wash with aqueous solution and 2×30mL water, and dry over anhydrous sodium sulfate to obtain a light yellow transparent liquid with a yield of 91.8% (calculated as perfluorohexylsulfonyl fluoride).

[...

Embodiment 2

[0062] This embodiment is the same as Embodiment 1, the difference is:

[0063] (2) Synthesis of PSF6A

[0064] Add high hydrogen silicone oil PMHS[2.5g, n(Si-H)=40.85mmol], NSF6[1.08g, n(C=C)=2.45mmol] and toluene 20mL into a 100mL three-neck round bottom flask, and then add The Karstedt catalyst with a concentration of 16.123 g / L was connected to a condensing device and a thermometer, magnetically stirred, and the oil bath was heated to 90°C. When the conversion rate of hydrosilylation reached 6%, AGE [4.40 g, n(C=C)=38.40 mmol] was added, and the reaction was continued until the conversion rate of hydrosilylation reaction was basically constant. It can be seen from Table 1 that when n(PMHS): n(NSF6): n(AGE)=10:0.6:9.4, the cmc and γ of PSF6AS cmc They are 0.12g / L and 32.8mN / m respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com