Preparation method and application of imprinted porous adsorption lithium/rubidium ion material

A porous adsorption, rubidium ion technology, applied in adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as limiting the dispersibility of CNTs, achieve stable structure, simple operation, and improve adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

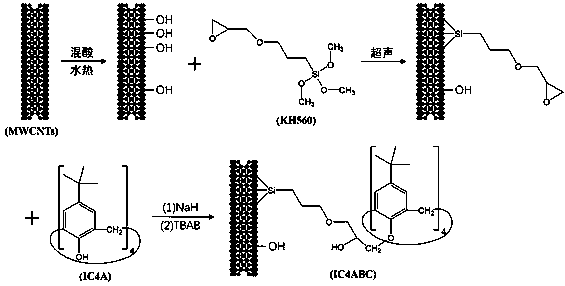

[0050] (1) Take 4 mL KH560 and 44 mL dry toluene in a 100 mL three-neck round bottom flask, add 2.5 g carboxylated carbon nanotubes and 0.2 mL triethylamine under magnetic stirring, stir in dry nitrogen and reflux at 130°C for 8h ; Filter, wash with toluene, acetone, deionized water and acetone in sequence, and vacuum dry at 90°C for 10 h; obtain KH560 grafted carbon nanotubes (KH560 / MWCNTs).

[0051] (2) Take 2.5 g IC4A in a 100 mL three-necked round bottom flask, add 50 mL toluene, add 1.3 g NaH, N under magnetic stirring 2 Under the protection of 90℃ oil bath for 40 minutes; let stand to take the supernatant, add tetrabutylammonium bromide and 2.5 gKH560 / MWCNTs, dry it in N 2 Stir in medium and react at 80°C under slight reflux for 30 h; filter while hot and wash until the filtrate is colorless and clear. The obtained solid was vacuum dried at 140°C for 12 hours to obtain the imprinted porous adsorbent material (IC4ABC).

[0052] Simulated salt lake brine adsorption experiment

...

Embodiment 2

[0055] (1) Take 4 mL KH560 and 38 mL dry toluene into a 100 mL three-neck round bottom flask, add 1.6 g carboxylated carbon nanotubes and 0.16 mL triethylamine under magnetic stirring, stir in dry nitrogen and reflux at 120°C for 6 hours ; Filter, wash with toluene, acetone, deionized water and acetone successively, and vacuum dry at 90°C for 8 h; obtain KH560 grafted carbon nanotubes (KH560 / MWCNTs).

[0056] (2) Take 2.5 g IC4A in a 100 mL three-necked round bottom flask, add 50 mL toluene, add 1.2 g NaH, N under magnetic stirring 2 Oil bath at 80℃ for 40 min under protection; stand still to take the supernatant, add tetrabutylammonium bromide and 1.7 gKH560 / MWCNTs, dry it in N 2 Stir at medium and reflux at 80°C for 22 h; filter while hot and wash until the filtrate is colorless and clear. The obtained solid was vacuum dried at 140°C for 10 h to obtain the imprinted porous adsorbent material (IC4ABC).

[0057] Simulated salt lake brine adsorption experiment

[0058] Add the prepar...

Embodiment 3

[0060] (1) Take 4 mL KH560 and 41 mL dry toluene into a 100 mL three-neck round bottom flask, add 2.2 g carboxylated carbon nanotubes and 0.12 mL triethylamine under magnetic stirring, stir in dry nitrogen and reflux at 130°C for 5h ; Filter, wash with toluene, acetone, deionized water and acetone successively, and dry under vacuum at 80°C for 10 h; obtain KH560 grafted carbon nanotubes (KH560 / MWCNTs).

[0061] (2) Take 2.5 g IC4A in a 100 mL three-necked round bottom flask, add 50 mL toluene, add 1.1 g NaH, N under magnetic stirring 2 Under the protection of 90℃ oil bath for 20 minutes; let stand to take the supernatant, add tetrabutylammonium bromide and 2.1 g KH560 / MWCNTs, dry it in N 2 Stir in the medium and react at 80°C under slight reflux for 26 h; filter while hot and wash until the filtrate is colorless and clear. The obtained solid was vacuum dried at 130°C for 8 hours to obtain the imprinted porous adsorbent material (IC4ABC).

[0062] Simulated salt lake brine adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com