A kind of ru-rh/c bimetallic catalyst and its preparation method and application

A bimetallic catalyst and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, amino compound preparation, etc., can solve the problems of poor catalytic performance and low MDA stereoselectivity, etc. Achieve high activity and selectivity, good electronic effect and catalytic hydrogenation performance, good effect of stereoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

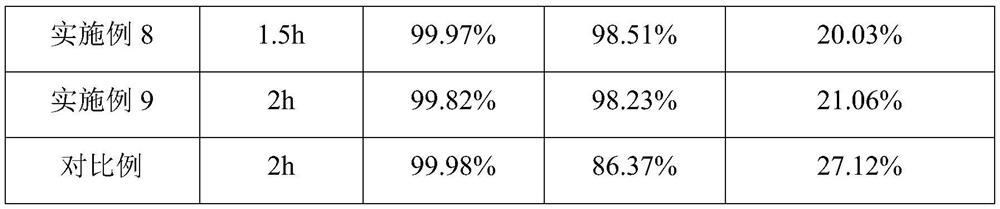

Examples

Embodiment 1

[0029] 1) Activated carbon was treated with 2w.t.% KOH for 2h, the liquid-solid ratio was 8:1, the temperature was 30°C, suction filtered, washed and dried.

[0030] 2) 1.22g RuCl 3 ·nH 2 O and 2g of polyvinylpyrrolidone (PVP) were dissolved in 200mL of deionized water, and the concentration of PVP in the system was 1w.t.%. Under vigorous stirring, use 10w.t.% NaOH solution to adjust the pH of the system to 5-6, add 40mL of 2.5w.t.% NaBH 4The solution was reduced and equilibrated for 1 hour to form a ruthenium sol.

[0031] 3) Synthesis of Ru-Rh composite nanoparticles: 0.13g RhCl 3 ·nH 2 O was dissolved in 5mL deionized water to form a rhodium precursor, and was added dropwise to the Ru sol system in step 2) under stirring, 2.37mL of 5w.t.% formaldehyde solution was added, and the pH of the system was adjusted to 8 with 10w.t.% NaOH solution. ~9, raise the temperature to 80°C, keep it warm for 2 hours, and control the pH value of the system to not be lower than 6.

[00...

Embodiment 2

[0034] Same as Example 1, the difference is that the PVP concentration of the system is 0.25w.t.%, the ruthenium content in the catalyst is 4.5%, and the rhodium content is 0.5%.

Embodiment 3

[0036] Same as Example 1, except that the activated carbon is treated with 2w.t.% LiOH, the PVP concentration of the system is 0.25w.t.%, the ruthenium content in the catalyst is 4.5%, and the rhodium content is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com