Magazine type stud welding gun

A stud welding and magazine-type technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unsatisfactory welding tasks, affecting welding efficiency, heavy workload, etc., achieving significant progress and industrial practicality Value, improvement of manual welding efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

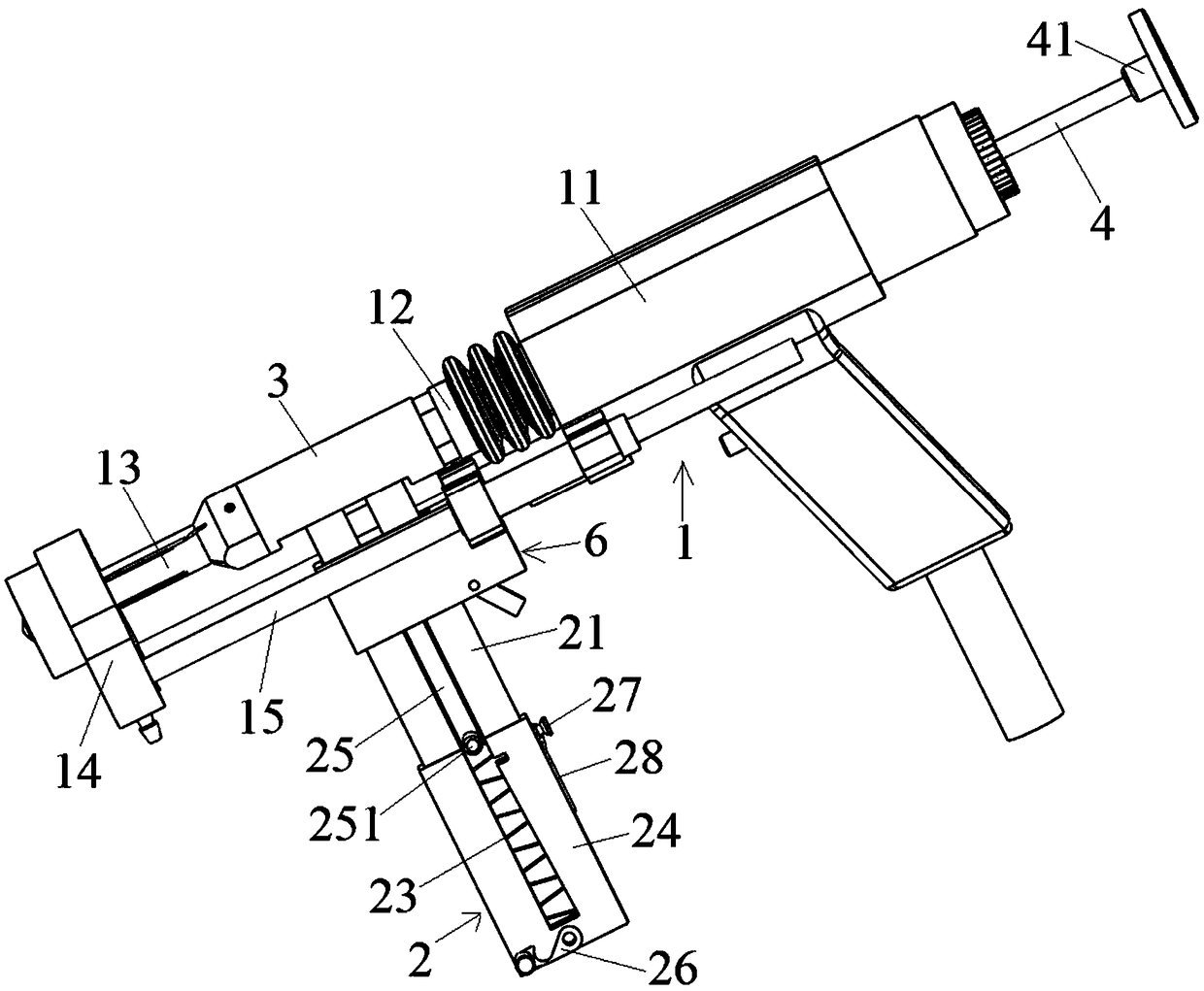

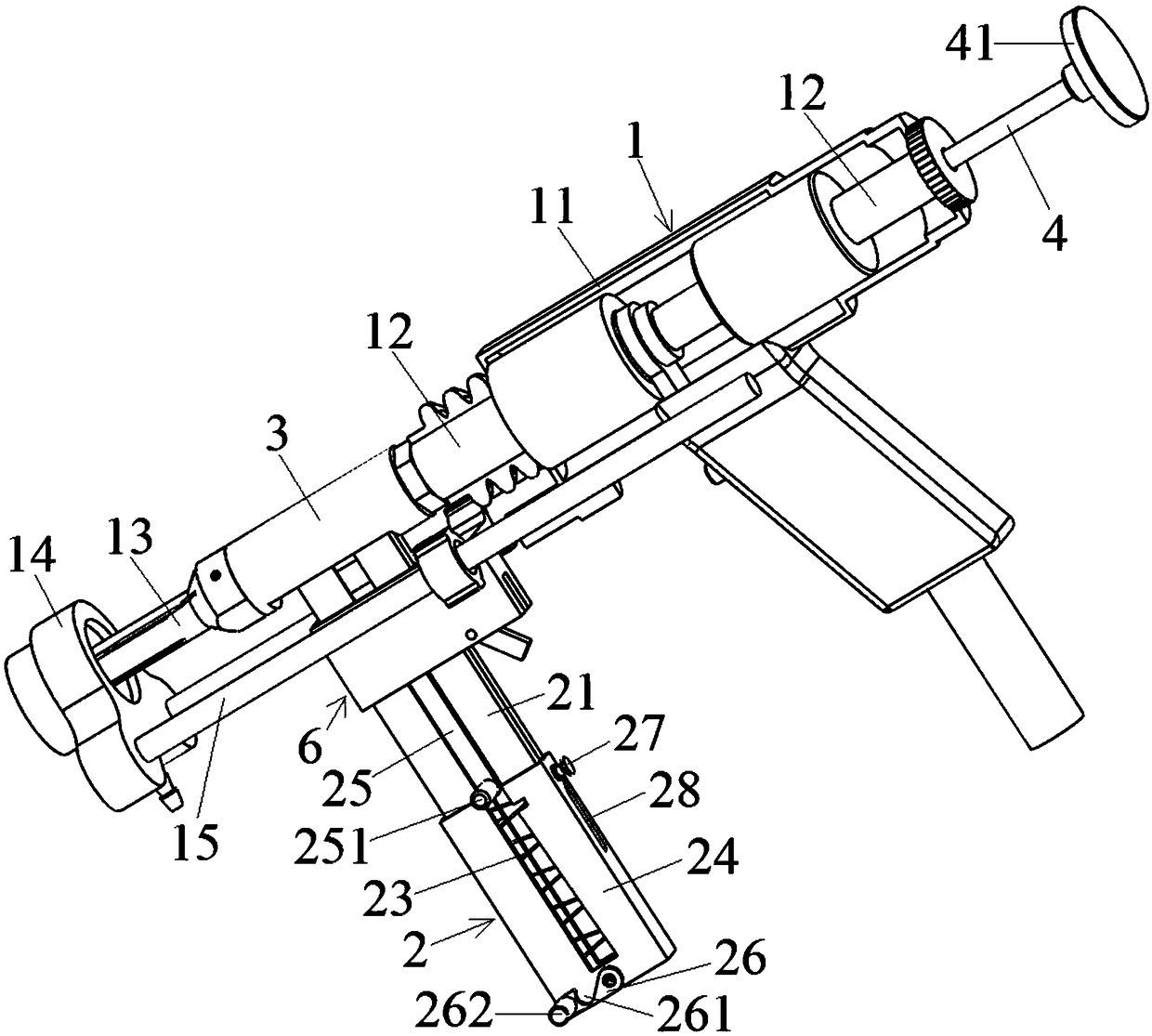

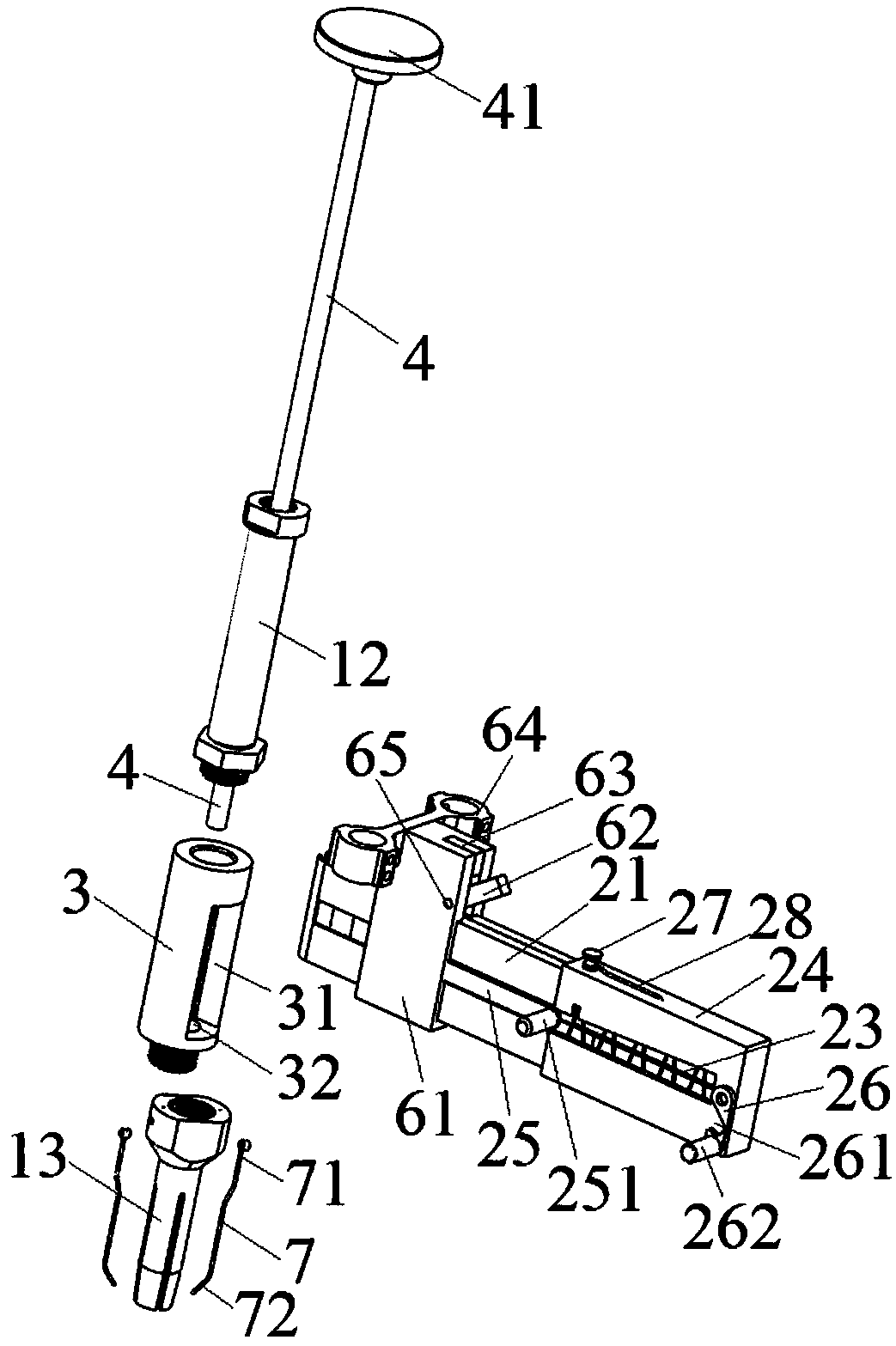

[0029] Please combine Figure 1 to Figure 3 Shown: a magazine-type stud welding torch provided in this embodiment includes a welding torch main body 1, a staple magazine 2, a nail rotating cylinder 3 and a nail feeding thimble 4, and the welding torch main body 1 includes a gun barrel 11, a main shaft body 12 and welding stud chuck 13, the upper end of turning nail barrel 3 is fixedly connected with main shaft body 12, and the lower end of turning nail barrel 3 is fixedly connected with welding stud chuck 13 (in the present embodiment, turning nail barrel 3 is connected with main shaft body 12 and The welding stud chucks 13 are all threaded, which can be easily disassembled and maintained. Of course, other fixed connection methods can also be used, such as welding, screw connection, etc., which are not specifically limited here). The inner side of the nail barrel 3 is provided with an opening 31, the head end of the staple magazine 2 passes through the opening 31 and is positi...

Embodiment 2

[0044] see Figure 9 with Figure 10 As shown, the difference between the magazine-type stud welding gun described in this embodiment and Embodiment 1 is only that: the gun barrel 11 extends to the lower end, and the gas shield 14 is directly fixed on the gun barrel 11, so that the The torch head takes up less space and is suitable for applications in welding places with small welding spacing.

[0045] To sum up: the present invention realizes the magazine-type nail feeding through the ingenious design of the nail loading magazine, the nail rotating cylinder and the nail feeding thimble, which can easily fill multiple welding nails at one time and realize automatic nail feeding, which can not only avoid manual filling The pain caused by welding workers can be achieved, and continuous welding for a certain period of time can be realized, so that the efficiency of manual welding can be significantly improved; moreover, the present invention also has the advantages of simple str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com