Experimental device of simulating ultrasonic-assisted wet process welding and application method thereof

A technology of wet welding and experimental equipment, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the mechanical properties of weld metal, improve comprehensive mechanical properties, promote discharge, and refine weld metal The effect of structure and grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and specific embodiments to help understand the content of the present invention. If there are no special regulations, the methods used in the present invention are conventional production methods; if there are no special regulations, the raw materials used are conventional commercial products.

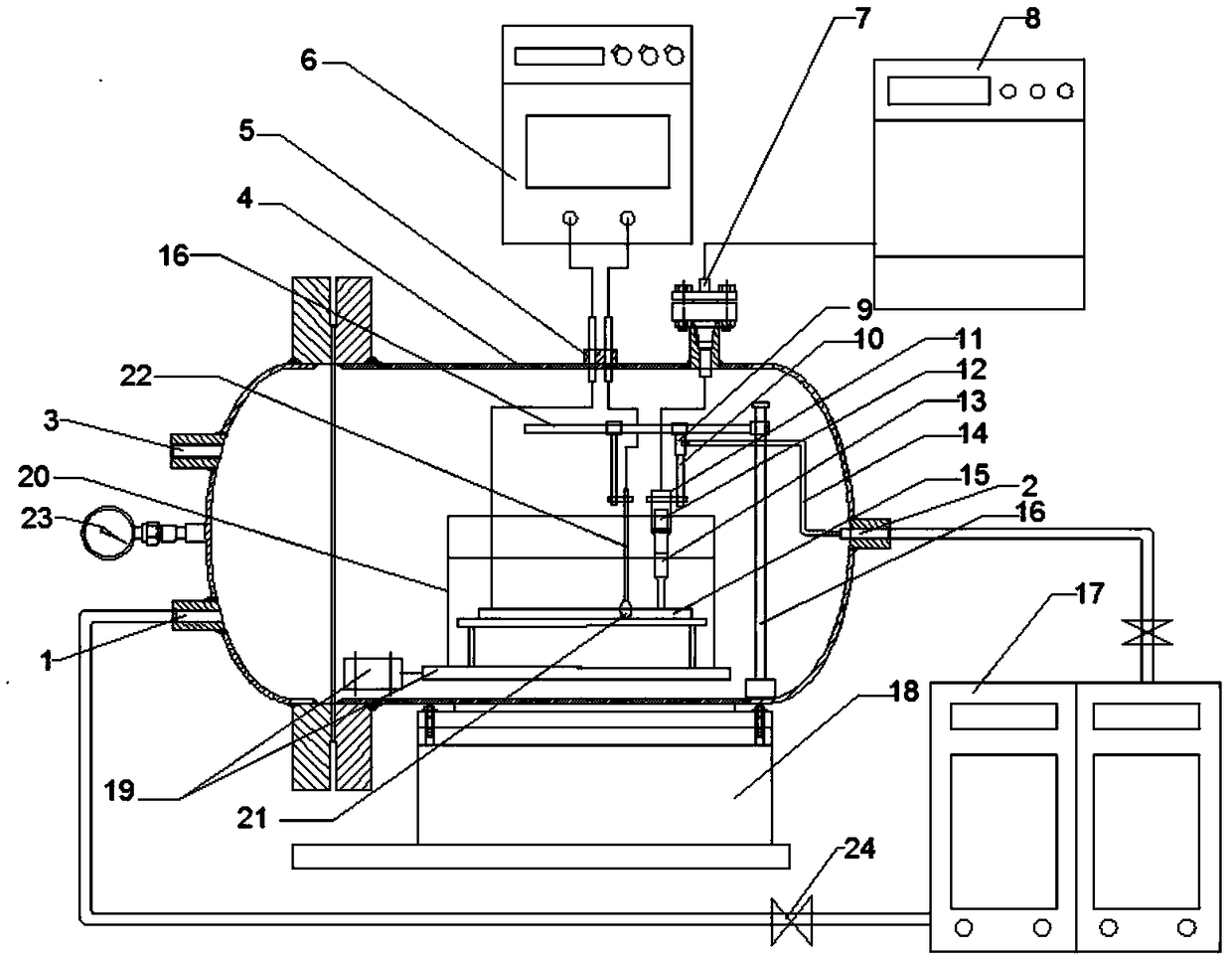

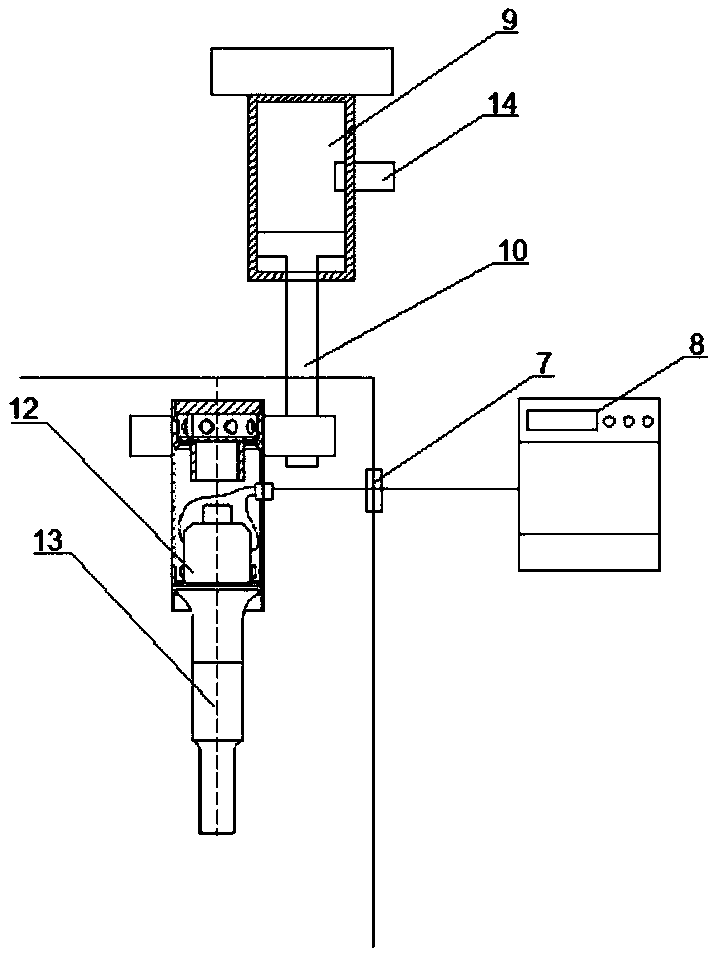

[0027] Such as figure 1 As shown, a simulated ultrasonic-assisted wet welding experimental device of the present invention includes a pressure chamber 4, an air supply system 17, and a power supply system. The walls of the pressure chamber 4 are respectively provided with a first air inlet pipe and a second air inlet pipe. 2 and pressure relief valve 3, the air supply system 17 is respectively connected to the first air inlet pipe 1 and the second air inlet pipe 1 through pipelines; the pressure chamber 4 is fixedly connected with a fixed bracket 16 and a walking mechanism 19, the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com