Plate turning extrusion device, and sludge dewatering system and method

A extrusion device and sludge dewatering technology, which is applied in the field of sludge dewatering system and flap extrusion device, can solve the problems of large environmental pollution and difficult treatment, and achieve the goal of improving sensitivity, improving dehydration efficiency and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

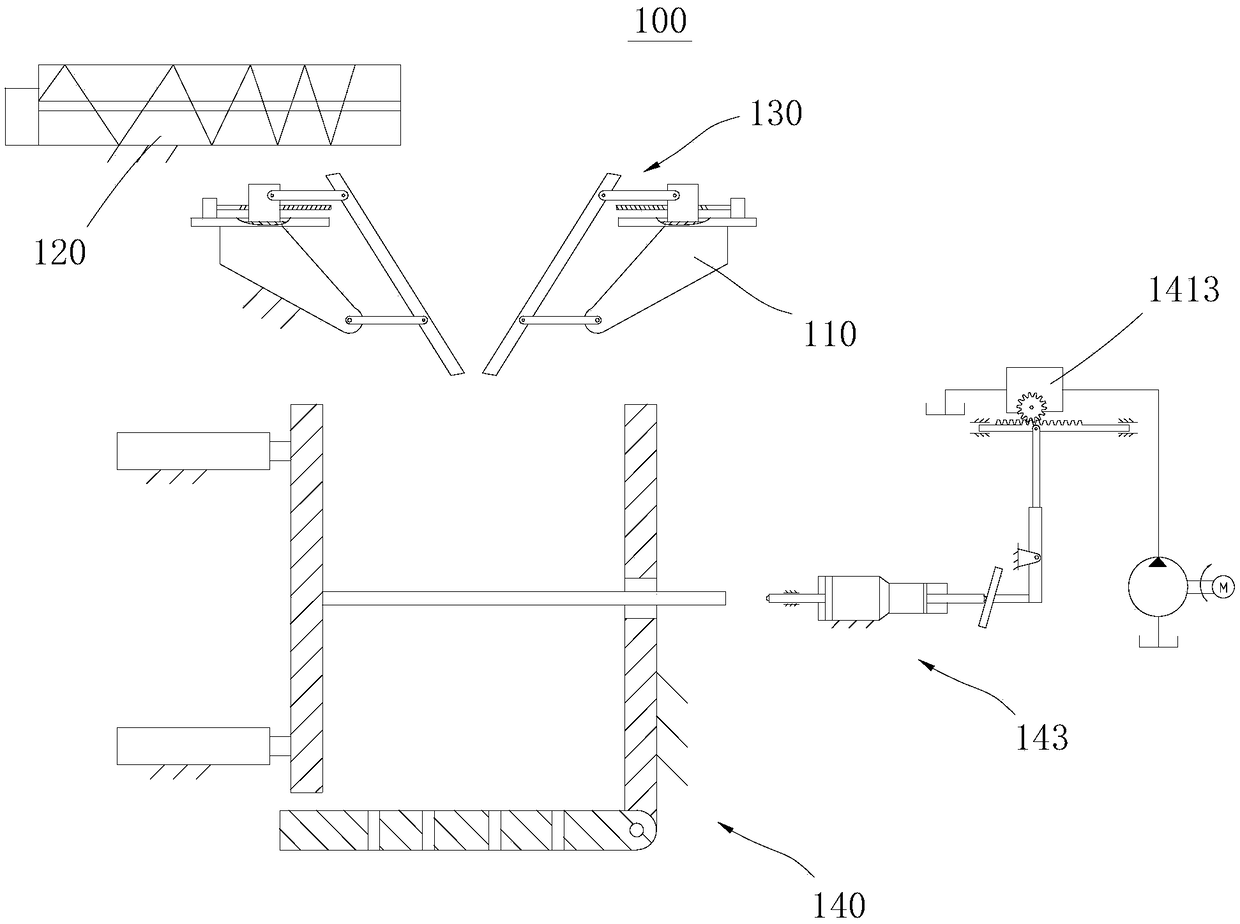

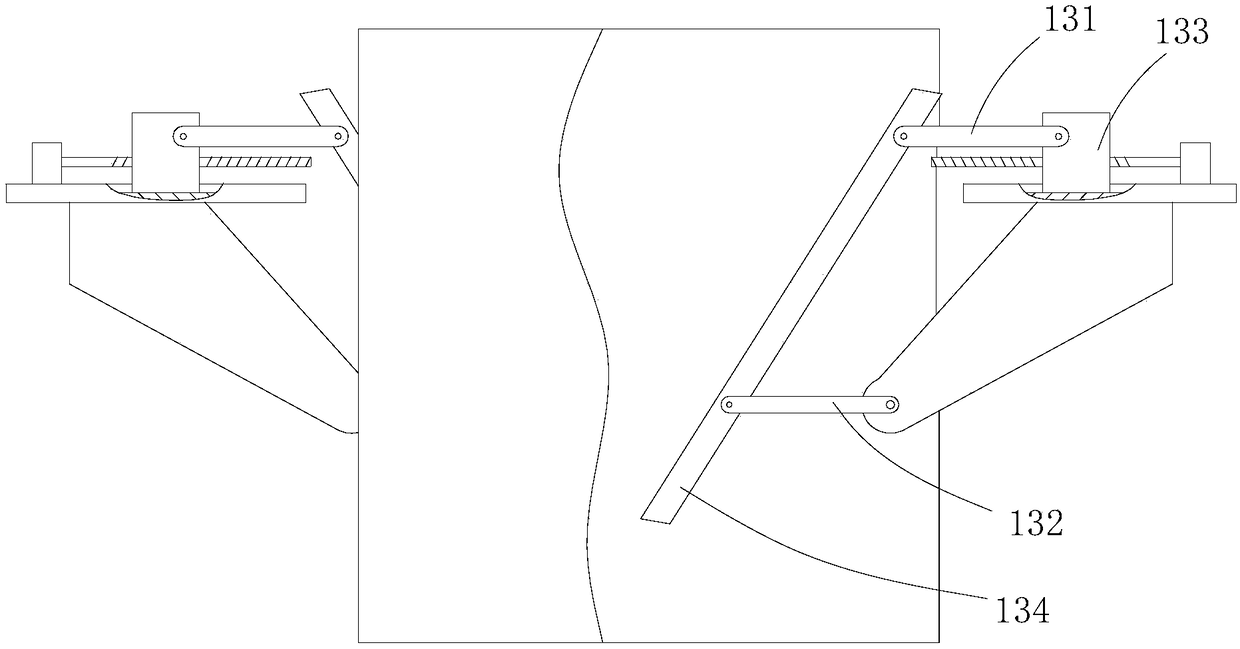

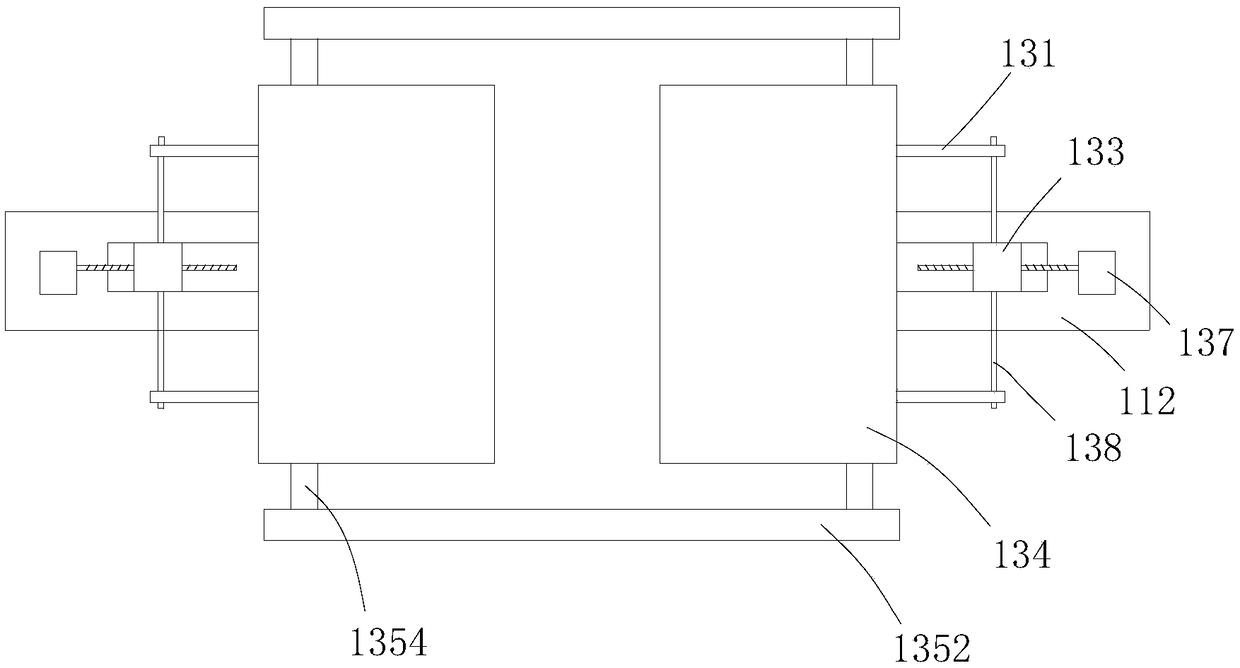

[0076] Please refer to figure 1 , this embodiment provides a sludge dewatering system 100, which is mainly used for dehydrating sludge with relatively high water content, so as to facilitate subsequent treatment. The above-mentioned dehydration system mainly includes a frame 110, a screw conveyor 120, a flap dehydrator 130 and a hydraulic dehydrator 140; the frame 110 is used to fix and install other components; the screw conveyor 120 is used to transport sludge to the flap dehydrator The preliminary dehydration is carried out in the hydraulic dehydrator 130, and the sludge after the preliminary dehydration falls into the hydraulic dehydrator 140 for deep dehydration.

[0077] Specifically, please continue to refer to figure 1 , the screw conveyor 120 is arranged horizontally and includes a conveying cylinder, a screw shaft and a driving motor. The conveying cylinder is arranged horizontally, one end of which is provided with a feed port, and the feed port is arranged facing...

Embodiment 2

[0100] A method for sludge dewatering, utilizing the sludge dewatering system 100 provided in embodiment 1; comprising the following steps:

[0101] a. Adjust the system to the initial state; specifically, adjust the overflow valve 1413 so that the oil supply pressure of the hydraulic system 141 is between 0.5MPA-1MPA; adjust the two extrusion devices so that the bottom of the two flaps 134 the smallest gap between

[0102] b. start the screw conveyor 120, and feed the sludge into the screw conveyor 120;

[0103] c. Preliminary dehydration: start two sliding drive mechanisms 137, so that the upper parts of the two extrusion plates are close to each other, and perform preliminary extrusion dehydration;

[0104] d. Start the two sliding drive mechanisms 137 to reset the two squeeze plates; then start the rotation drive mechanism to make the two squeeze plates move away from each other; make the sludge fall into the hydraulic dehydrator 140 below;

[0105] e. Deep dehydration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com