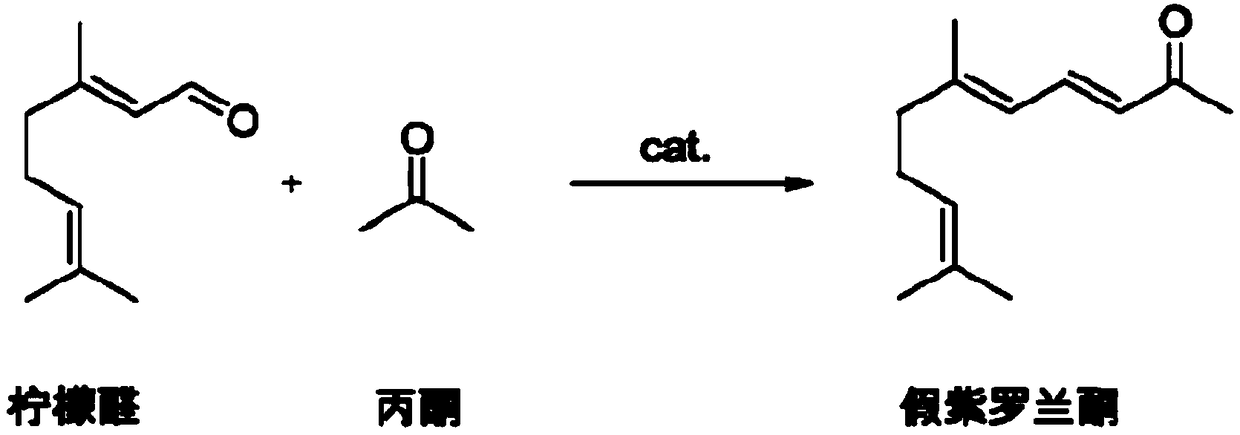

Method for catalytic synthesis of pseudo ionone through solid super base

A technology of pseudoionone and solid super base, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve the problems of high toxicity and corrosion, low yield, etc. Easy to prepare, high catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of super strong solid base:

[0031] Add 14.8g of magnesium nitrate and 10.65g of zirconium nitrate to 30mL of water and 100mL of ethanol to make a solution, add 1mol / L LiOH to the solution, the pH value is 11, reflux and aging for 36 hours, centrifuge, the precipitate is washed with water, dried overnight, in nitrogen Under the atmosphere, the precipitate was put into a muffle furnace and calcined at a high temperature of 800° C. for 3 hours to obtain a solid superbase catalyst A with a Li content of 2%.

[0032] 2) Add 1 mol of citral, 1 mol of acetone, and 0.05 mol of the solid superbase catalyst A prepared above into the reactor, under the protection of nitrogen, the reaction temperature is 150°C for aldol condensation reaction for 3 hours, and the normal pressure is maintained during the reaction. After the reaction is finished, cool down and filter to take the filtrate, add acetic acid dropwise for neutralization, wash with water to remove the aceti...

Embodiment 2

[0034] 1) Preparation of super strong solid base:

[0035] Add 14.8g of magnesium nitrate and 8.52g of zirconium nitrate to 30mL of water and 100mL of ethanol to make a solution, add 1mol / L LiOH to the solution, the pH value is 11, reflux and aging for 36 hours, centrifuge, the precipitate is washed with water, dried overnight, in nitrogen Under the atmosphere, the precipitate was put into a muffle furnace and calcined at a high temperature of 800° C. for 3 hours to obtain a solid superbase catalyst B with a Li content of 0.7%.

[0036] 2) Add 1 mol of citral, 3 mol of acetone, and 0.05 mol of the solid superbase catalyst B prepared above into the reactor, and under the protection of nitrogen, the reaction temperature is 150°C for aldol condensation reaction for 3 hours, and normal pressure is maintained during the reaction. After the reaction is finished, cool down and filter to take the filtrate and add acetic acid dropwise for neutralization, then wash with water to remove ...

Embodiment 3

[0038] 1) Preparation of super strong solid base:

[0039] Add 14.8g of magnesium nitrate and 10.65g of zirconium nitrate to 30mL of water and 100mL of ethanol to make a solution, add 1mol / L LiOH to the solution, the pH value is 10, reflux and aging for 36 hours, centrifuge, the precipitate is washed with water, dried overnight, in nitrogen Under the atmosphere, the precipitate was put into a muffle furnace and calcined at a high temperature of 800° C. for 3 hours to obtain a solid superbase catalyst C with a Li content of 1.1%.

[0040] 2) Add 1 mol of citral, 1 mol of acetone, and 0.1 mol of the solid superbase catalyst C prepared above into the reactor, under the protection of nitrogen, the reaction temperature is 150°C for aldol condensation reaction for 3 hours, and the normal pressure is maintained during the reaction. After the reaction is finished, cool down and filter to take the filtrate, add acetic acid dropwise for neutralization, wash with water to remove the acetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com