Aluminium alloy for cable with high conductivity

A high-conductivity, aluminum alloy technology, applied in the field of aluminum alloys, can solve the problems that cannot cover the rising market share of aluminum alloy cables, high resistivity of aluminum alloy cables, and high heating temperature, and improve high-temperature creep performance and fatigue resistance. , The effect of fatigue resistance and creep resistance improvement, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

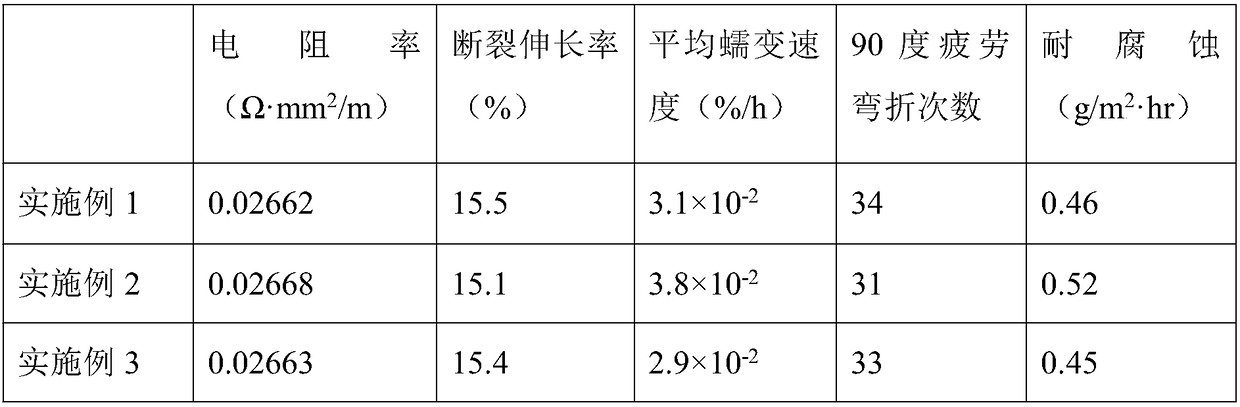

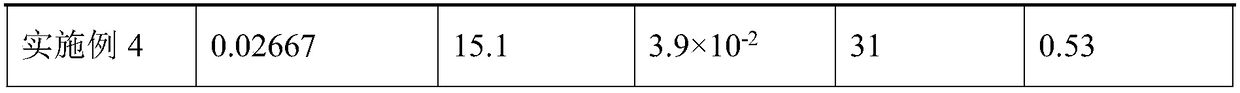

Examples

Embodiment 1

[0027] A high-conductivity aluminum alloy for cables, comprising the following components by weight percentage:

[0028] Cu 0.06%, Ca 0.5%, Ga 1.3%, modified graphene 0.3%, and the balance is Al and impurities.

[0029] The preparation method of modified graphene comprises the following steps:

[0030] 1) Nano-TiO 2 and Fe powder into a three-dimensional mixer, mixed at room temperature for 2 hours to obtain mixed powder A; the nano-TiO 2 The mass ratio to Fe powder is 10:1.

[0031] 2) Put lanthanum oxide and zinc powder into a three-dimensional mixer, mix at room temperature for 10 hours to obtain mixed powder B, and set aside; the mass ratio of lanthanum oxide to zinc powder is 1:6.

[0032] 3) Put the mixture A of step 1), the mixture B of step 2), graphene powder and polyacrylamide into the three-dimensional mixer according to the mass ratio of 80:8:1, and mix them at room temperature for 13 hours Obtain modified graphene.

Embodiment 2

[0034] A high-conductivity aluminum alloy for cables, comprising the following components by weight percentage:

[0035] Cu 0.03%, Ca 0.2%, Ga 0.8%, modified graphene 0.2%, and the balance is Al and impurities.

[0036] The preparation method of modified graphene comprises the following steps:

[0037] 1) Nano-TiO 2 and Fe powder into a three-dimensional mixer, mixed at room temperature for 3 hours to obtain mixed powder A; the nano-TiO 2 The mass ratio to Fe powder is 13:1.

[0038] 2) Put lanthanum oxide and zinc powder into a three-dimensional mixer, mix at room temperature for 8 hours to obtain mixed powder B, and set aside; the mass ratio of lanthanum oxide and zinc powder is 1:4.

[0039] 3) Put the mixture A of step 1), the mixture B of step 2), graphene powder and polyacrylamide into the three-dimensional mixer according to the mass ratio of 83:5:1, and mix at room temperature for 12 hours Obtain modified graphene.

Embodiment 3

[0041] A high-conductivity aluminum alloy for cables, comprising the following components by weight percentage:

[0042] Cu 0.09%, Ca 0.6%, Ga 1.4%, modified graphene 0.4%, and the balance is Al and impurities.

[0043] The preparation method of modified graphene comprises the following steps:

[0044] 1) Nano-TiO 2 and Fe powder into a three-dimensional mixer, mixed at room temperature for 2 hours to obtain mixed powder A; the nano-TiO 2 The mass ratio to Fe powder is 16:1.

[0045] 2) Put lanthanum oxide and zinc powder into a three-dimensional mixer, mix at room temperature for 12 hours to obtain mixed powder B, and set aside; the mass ratio of lanthanum oxide to zinc powder is 1:8.

[0046] 3) Put the mixture A of step 1), the mixture B of step 2), graphene powder and polyacrylamide into the three-dimensional mixer according to the mass ratio of 85:6:1, and mix at room temperature for 13 hours Obtain modified graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com