High-strength magnesium alloy sectional material as well as preparation process and application

A preparation process, magnesium alloy technology, applied in the field of aviation containers, high-strength magnesium alloy profiles and its preparation process and application field, can solve the problem that deformed magnesium alloy products have not found a huge application market, and achieve high comprehensive room temperature The effects of mechanical properties and plasticity, high efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation process of the high-strength magnesium alloy profile has the same advantages as the above-mentioned high-strength magnesium alloy profile.

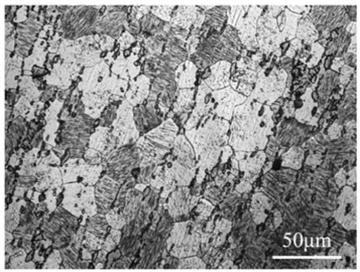

[0070] In a preferred embodiment, a typical temperature-varying homogenization treatment includes: raising the temperature from room temperature to 200-300°C and keeping it for 2-4h; then raising the temperature to 410-480°C and keeping it for 6-15h; then raising the temperature to 520- After holding at 530°C for 8-10 hours; cooling to 400-480°C with the furnace, and then cooling rapidly at a cooling rate of 3-40°C / s.

[0071]The variable temperature homogenization treatment includes four stages: the first homogenization treatment stage: the temperature is raised from room temperature to 200-300 ° C, and kept for 2-4 hours; room temperature refers to the ambient temperature under heating conditions, and the heating temperature includes but is not limited to 200 °C, 250°C or 300°C; holding time includes but not limit...

Embodiment 1

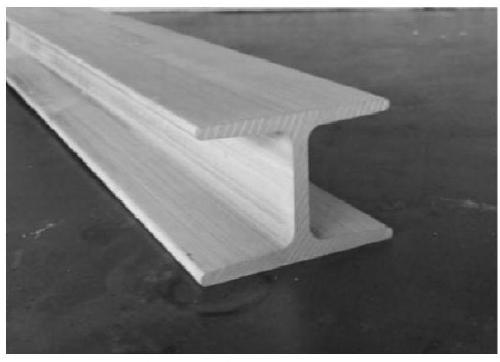

[0098] The products produced are magnesium alloy I-beam profiles.

[0099] A magnesium alloy extrusion forming process, comprising the following steps:

[0100] (1) The temperature-varying homogenization treatment of magnesium alloy ingots includes: charging with the furnace, raising the temperature from room temperature to 200°C within 30 minutes, and holding it for 4 hours; then raising the temperature to 410°C within 40 minutes, holding it for 15 hours; and then heating up within 30 minutes Keep warm for 10 hours after reaching 520°C; then close the furnace, cool down to 400°C with the furnace, rapidly cool at a rate of 3°C / s, and take it out;

[0101] The magnesium alloy ingot includes the following components in mass percentage: Gd 9%, Y 5%, Zn 1.5%, Mn 1.5%, and the balance is Mg and unavoidable impurities;

[0102] (2) Preheat the pure magnesium ingot, magnesium alloy ingot, extrusion cylinder and extrusion die; is 450°C;

[0103] (3) The preheated extrusion die is s...

Embodiment 2

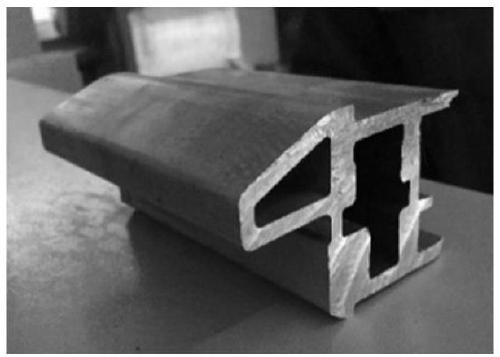

[0107] The products produced are magnesium alloy profiles.

[0108] A magnesium alloy extrusion forming process, comprising the following steps:

[0109] (1) The temperature-changing and homogenizing treatment of magnesium alloy ingots includes: charging with the furnace, heating from room temperature to 300°C within 30 minutes, and holding for 2 hours; then raising the temperature to 480°C within 40 minutes, holding for 6 hours; and then heating up within 30 minutes Keep warm for 8 hours after reaching 530°C; then close the furnace, cool down to 460°C with the furnace, rapidly cool at a rate of 40°C / s, and take it out;

[0110] The magnesium alloy ingot includes the following components in mass percentage: Gd 8%, Y 6%, Zn 1.2%, Mn 1.2%, and the balance is Mg and unavoidable impurities;

[0111] (2) Preheat pure magnesium ingots, magnesium alloy ingots, extrusion cylinders and extrusion dies; the preheating temperature of pure magnesium ingots, magnesium alloy ingots and extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com