High-strength dual-phase steel dp780 applied to construction machinery vehicles and its production method

A technology of DP780, production method, applied in the field of metallurgy, can solve the problems of poor toughness, low mechanical strength, high yield-to-strength ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

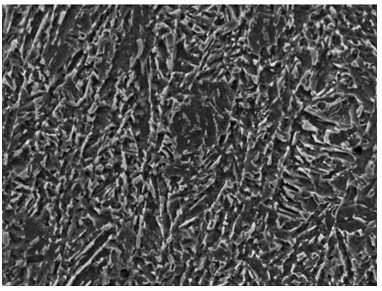

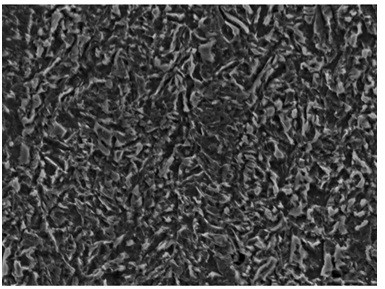

Image

Examples

Embodiment 1

[0032] This embodiment is applied to the high-strength dual-phase steel DP780 for construction machinery vehicles with a thickness of 30 mm, and its chemical composition and mass percentage are shown in Table 1.

[0033] The production method of this embodiment applied to the high-strength dual-phase steel DP780 for construction machinery vehicles includes converter smelting, LF refining, continuous casting, heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0034] (1) Converter smelting process: O: 600ppm in steel is controlled, and the amount of slag after tapping is 0.01% of molten steel to ensure the cleanliness of molten steel;

[0035] (2) LF refining process: control the refining time for 35 minutes, operate under 0Pa micro-positive pressure throughout the process to prevent molten steel from absorbing nitrogen; use 6kg / t steel lime, 1.4kg / t steel aluminum wire, and 1kg / t steel aluminum pellets to make white slag Desulfurizat...

Embodiment 2

[0042] This embodiment is applied to the high-strength dual-phase steel DP780 for construction machinery vehicles with a thickness of 30 mm, and its chemical composition and mass percentage are shown in Table 1.

[0043] The production method of this embodiment applied to the high-strength dual-phase steel DP780 for construction machinery vehicles includes converter smelting, LF refining, continuous casting, heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0044] (1) Converter smelting process: O: 550ppm in steel is controlled, and the amount of slag after tapping is 0.006% of molten steel to ensure the cleanliness of molten steel;

[0045] (2) LF refining process: control the refining time for 40 minutes, and operate under 20Pa micro-positive pressure throughout the whole process to prevent molten steel from absorbing nitrogen; use 5kg / t steel lime, 1.3kg / t steel aluminum wire, and 0.8kg / t steel aluminum particles to make white ...

Embodiment 3

[0052] This embodiment is applied to the high-strength dual-phase steel DP780 for construction machinery vehicles with a thickness of 25mm, and its chemical composition and mass percentage are shown in Table 1.

[0053] The production method of this embodiment applied to the high-strength dual-phase steel DP780 for construction machinery vehicles includes converter smelting, LF refining, continuous casting, heating, controlled rolling, and controlled cooling. The specific process steps are as follows:

[0054] (1) Converter smelting process: control O: 500ppm in steel, and 0.008% molten steel amount of slag after tapping to ensure the cleanliness of molten steel;

[0055] (2) LF refining process: control the refining time for 38 minutes, and operate under a slight positive pressure of 50 Pa throughout the process to prevent molten steel from absorbing nitrogen; use 10kg / t steel lime, 1.1kg / t steel aluminum wire, and 0.7kg / t steel aluminum particles to make white Slag desulfuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com