Cotton top cutting agent and preparation method thereof

A technology for topping agent and cotton, applied in the fields of botanical equipment and methods, biocides, animal repellants, etc., can solve the problems of poor timeliness, time-consuming and laborious, low efficiency, etc., and achieve high timeliness and ensure topping quality. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

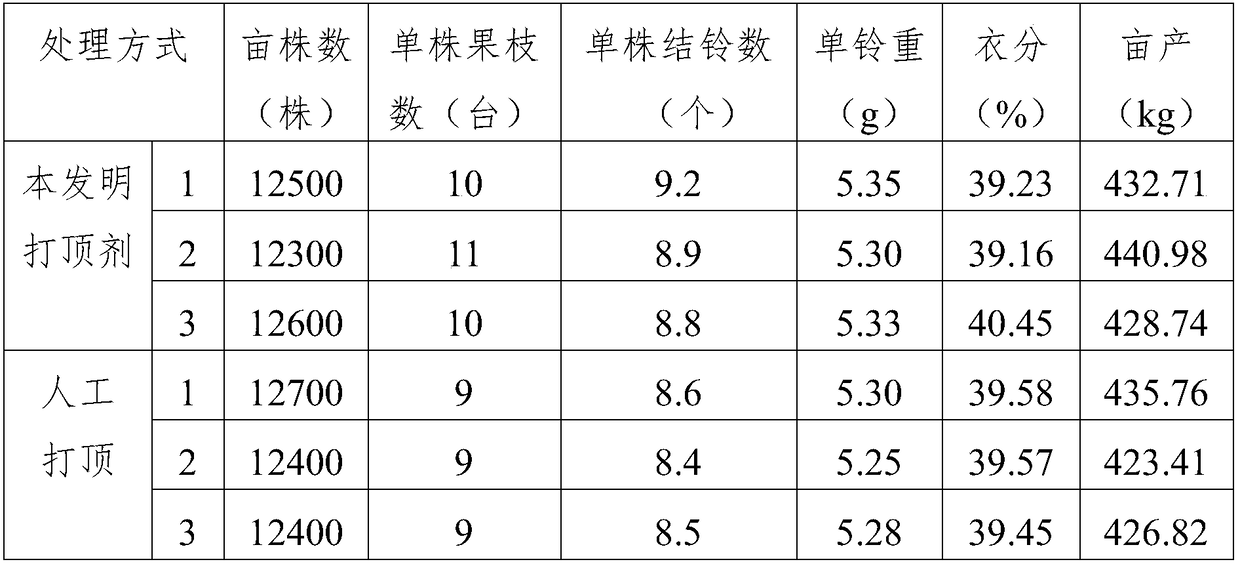

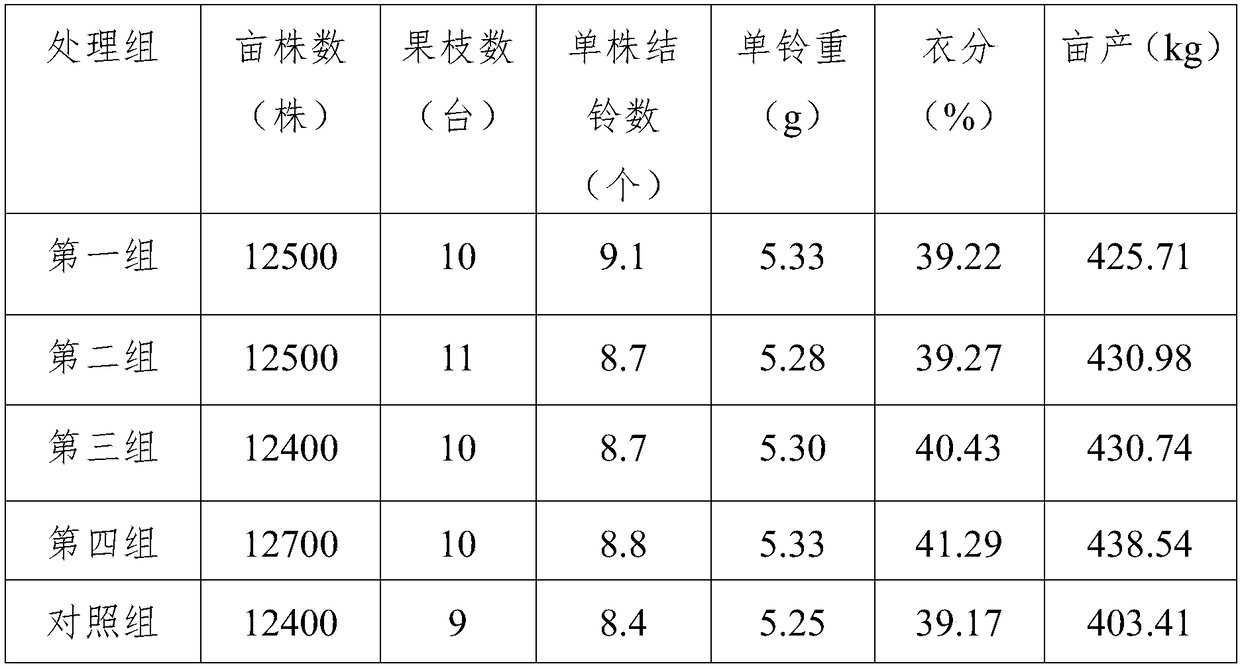

Embodiment 1

[0028] The cotton topping agent provided in this embodiment, the raw material ratio is: 0.3 parts of tribenuron-methyl, 30 parts of sec-butaline, 10 parts of flubenzamine, calcium dodecylbenzenesulfonate, phenethylphenol polyoxyethylene ether 10.7 parts of mixed emulsifier, 10 parts of dimethylformamide, and 35 parts of xylene solvent prepared according to the mass ratio of 1:1:1.

[0029] The preparation method of the cotton topping agent comprises the following steps: taking by weighing the corresponding parts of tribenuron-methyl, sec-butaline, flumethamine, emulsifier, dimethylformamide, and xylene solvent, for subsequent use; , Zhongbutingling, and flumetriamine, and stir while mixing, add an appropriate amount of xylene solvent, and stir while adding, stop after dissolving, and stir evenly; add emulsifier and dimethylformamide, and stir for 25 minutes; add the remaining All the xylene solvents are mixed and stirred for 10 minutes, and the preparation is completed after a...

Embodiment 2

[0033] The cotton topping agent provided in this embodiment, the raw material ratio is: 0.2 parts of trisulfuron-methyl, 30 parts of sec-butaline, 11 parts of flubenzamine, calcium dodecylbenzenesulfonate, phenethylphenol polyoxyethylene ether , Tristyrylphenol polyoxyethylene polyoxypropylene ether according to the mass ratio of 1:1:1 mixed emulsifier 8.6 parts, 8 parts of dimethylformamide, 37 parts of xylene solvent.

[0034] The preparation method of the cotton topping agent comprises the following steps: taking by weighing the corresponding parts of tribenuron-methyl, sec-butaline, flumethamine, emulsifier, dimethylformamide, and xylene solvent, for subsequent use; , Zhongbutingling, and flumetriamine, and stir while mixing, add an appropriate amount of xylene solvent, and stir while adding, stop after dissolving, and stir evenly; add emulsifier and dimethylformamide, and stir for 25 minutes; add the remaining All the xylene solvents were mixed and stirred for 5 minutes, ...

Embodiment 3

[0037]The cotton topping agent provided in the present embodiment, the raw material ratio is: 0.4 parts of Trisulfuron-methyl, 29 parts of Zhongbuling, 13 parts of flumethamine, calcium dodecylbenzenesulfonate, phenethylphenol polyoxyethylene ether 12.7 parts of mixed emulsifier prepared according to the mass ratio of 2:1:1, tristyrylphenol polyoxyethylene polyoxypropylene ether, 5 parts of dimethylformamide, and 40 parts of xylene solvent.

[0038] The preparation method and usage method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com