Fruit taste tablet candy and production method thereof

A technology for compressing sugar and fruit flavors, which is applied in the fields of confectionery, confectionary industry, food science, etc., can solve the problems of affecting food flavor and complex process, achieve good mixing effect, solve environmental pollution, and solve resource waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

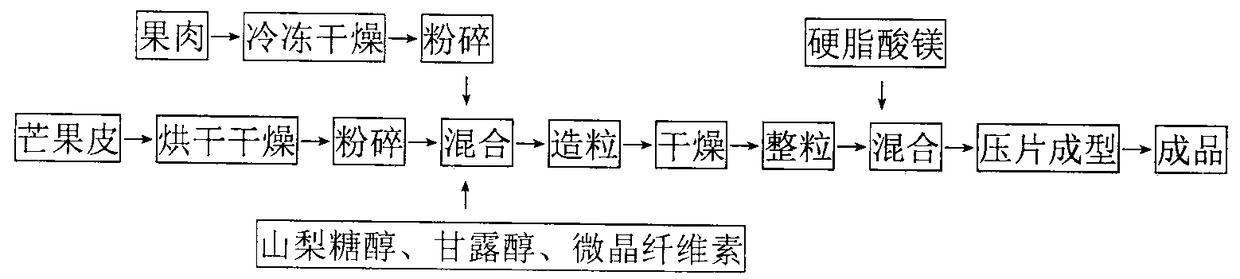

[0019] The manufacture method of the mango-flavored tablet candy of the present embodiment comprises the following steps:

[0020] (1) Fresh mangoes are washed and peeled directly, and the thickness of the peel is controlled within 0.05 cm; the peel is spread on a tray and dried in a vacuum drying oven until the peel is curled and crisp. Put the dried mango skin in a traditional Chinese medicine powder machine and pulverize it into small particles; after drying it again for 1 hour, use an ultrafine pulverizer to pulverize it into a fine peel fiber powder, pass through a 200-mesh sieve, and prepare Get mango peel powder.

[0021] (2) After the fresh mangoes are peeled and pitted, the pulp is pulped, the slurry is placed in a glass dish, and frozen in a refrigerator at -20°C for 6 hours to make it firm. Turn on the freeze dryer to pre-cool for half an hour, the temperature drops to -40°C, put the frozen mango pulp in the tray of the freeze dryer, under the conditions of a vacuu...

Embodiment 2

[0025] The manufacture method of the mango-flavored tablet candy of the present embodiment comprises the following steps:

[0026] (1) Fresh mangoes are washed and peeled directly, and the thickness of the peel is controlled within 0.05 cm; the peel is spread on a tray and dried in a vacuum drying oven until the peel is curled and crisp. Put the dried mango skin in a traditional Chinese medicine powder machine and pulverize it into small particles; after drying it again for 1 hour, use an ultrafine pulverizer to pulverize it into a fine peel fiber powder, pass through a 200-mesh sieve, and prepare Get mango peel powder.

[0027] (2) After the fresh mangoes are peeled and pitted, the pulp is pulped, the slurry is placed in a glass dish, and frozen in a refrigerator at -20°C for 6 hours to make it firm. Turn on the freeze dryer to pre-cool for half an hour, the temperature drops to -40°C, put the frozen mango pulp in the tray of the freeze dryer, under the conditions of a vacuu...

Embodiment 3

[0031] The manufacture method of the orange-flavored compressed tablet sugar of the present embodiment comprises the following steps:

[0032] (1) Fresh mangoes are washed and peeled directly, and the thickness of the peel is controlled within 0.05 cm; the peel is spread on a tray and dried in a vacuum drying oven until the peel is curled and crisp. Put the dried mango skin in a traditional Chinese medicine powder machine and pulverize it into small particles; after drying it again for 1 hour, use an ultrafine pulverizer to pulverize it into a fine peel fiber powder, pass through a 200-mesh sieve, and prepare Get mango peel powder.

[0033] (2) After peeling the fresh citrus, pulp the pulp, put the slurry in a glass dish, and freeze it in a refrigerator at -20°C for 6 hours to make it firm. Turn on the freeze dryer to pre-cool for half an hour, the temperature drops to -40°C, put the frozen orange pulp in the tray of the freeze dryer, under the conditions of a vacuum of 0.1 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com