Production technology for low-salt sauce-flavored thick broad-bean sauce and product thereof

A production process, the technology of fragrant bean paste, which is applied in the production process of bean paste, can solve the problems of not being able to highlight the aroma of the sauce, affect the taste and health, and consume too much salt, so as to achieve an excellent taste experience, The effect of outstanding sauce aroma and strong sauce aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

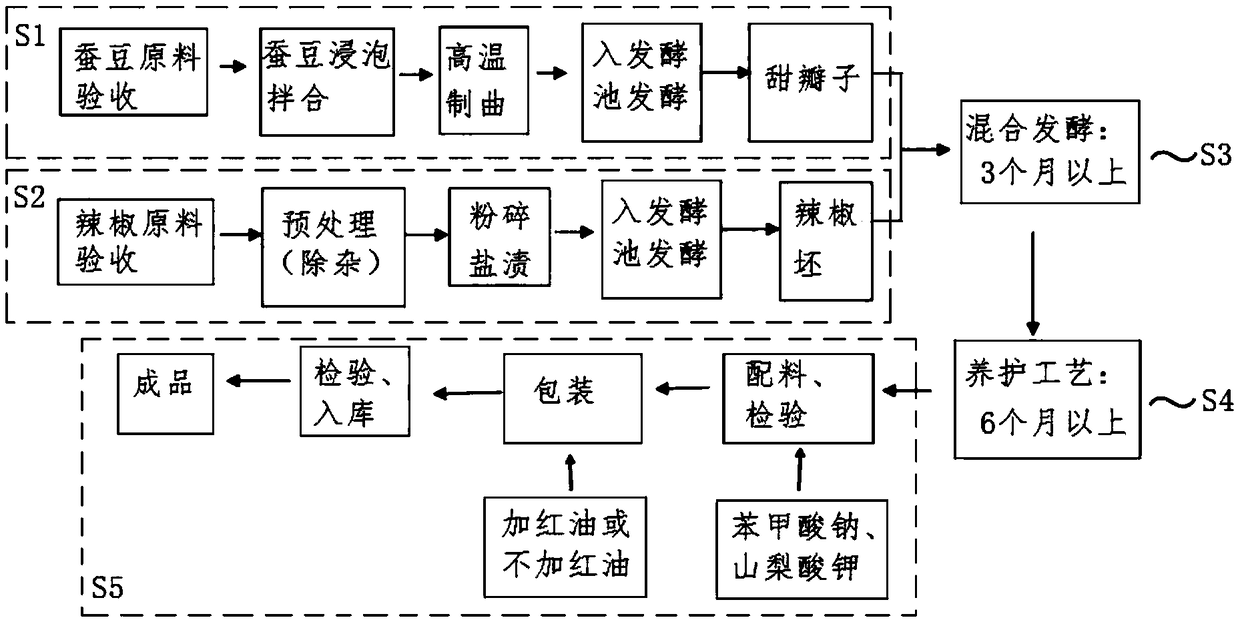

Method used

Image

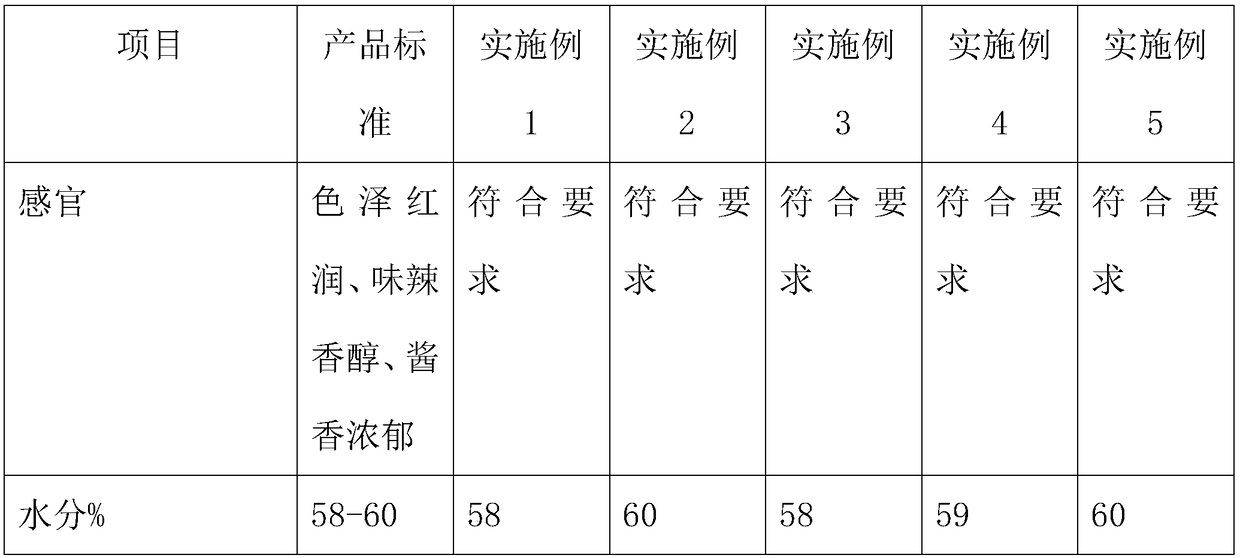

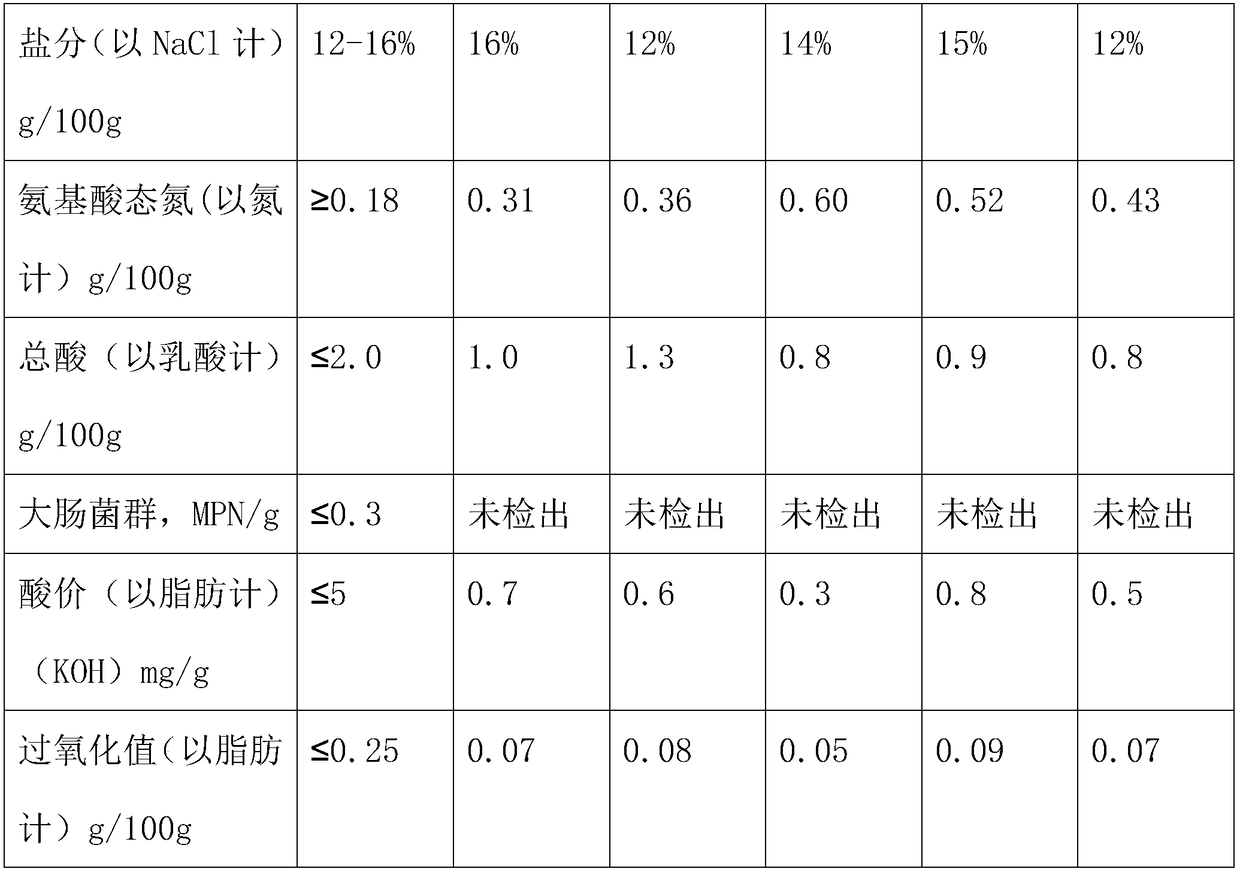

Examples

Embodiment 1

[0052] This embodiment is to determine the description of the whole production process of a process parameter:

[0053] A kind of production technology of thin-salted sauce-flavored bean paste, comprises the following steps:

[0054] 1) Sweet watercress koji making and fermentation: Soak the bean sprouts in warm water at 40-50°C for 20-40 minutes, remove and drain; according to the weight of the bean sprouts before soaking Weigh aspergillus oryzae, weigh 6% of the weight of the bean sprouts before soaking, weigh the flour, mix the bean sprouts, koji essence and flour evenly, place them in a koji pond to make koji at high temperature, and put them in a fermentation tank for 8 months of fermentation after 2 days to obtain sweet bean seeds. spare;

[0055] Among them, high-temperature koji making is: put the watercress evenly mixed with koji essence and flour into the koji pool, lay the billet flat, loose and not pressed, with a thickness of 20cm, and the temperature of the bil...

Embodiment 2

[0061] This embodiment is to determine the description of the whole production process of a process parameter:

[0062] A kind of production technology of thin-salted sauce-flavored bean paste, comprises the following steps:

[0063] 1) Sweet watercress koji making and fermentation: Soak the bean sprouts in warm water at 40-50°C for 20-40 minutes, remove and drain; according to the weight of the bean sprouts before soaking Weigh Aspergillus oryzae, weigh 10% of the weight of the bean sprouts before soaking, weigh the flour, mix the bean sprouts, koji essence and flour evenly, place them in a koji pond to make koji at high temperature, and put them in a fermentation tank to ferment for 7 months after 2 days to obtain sweet petals. spare;

[0064] Among them, high-temperature koji making is: put the watercress evenly mixed with koji essence and flour into the koji pool, lay the billet flat, loose and not pressed, with a thickness of 25cm, and the temperature of the billet in t...

Embodiment 3

[0070] This embodiment is to determine the description of the whole production process of a process parameter:

[0071] A kind of production technology of thin-salted sauce-flavored bean paste, comprises the following steps:

[0072] 1) Sweet watercress koji making and fermentation: Soak the bean sprouts in warm water at 40-50°C for 20-40 minutes, remove and drain; according to the weight of the bean sprouts before soaking Weigh Aspergillus oryzae, weigh 8% of the weight of the bean sprouts before soaking, weigh the flour, mix the bean sprouts, koji essence and flour evenly, place them in a koji pond to make koji at high temperature, and put them in a fermentation tank for fermentation for 6 months after 2 days to obtain sweet petals. spare;

[0073]Among them, high-temperature koji making is: put the watercress evenly mixed with koji essence and flour into the koji pool, lay the billet flat, loose and not pressed, with a thickness of 28cm, and the temperature of the billet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com