Continuous flow production control method, device and system for microreactor

A production control method and micro-reactor technology, applied in control/regulation systems, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., capable of solving reaction product fluctuations, unstable output products, lack of detection and regulation Control methods and other issues to achieve the effect of ensuring stable output and realizing real-time analysis and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

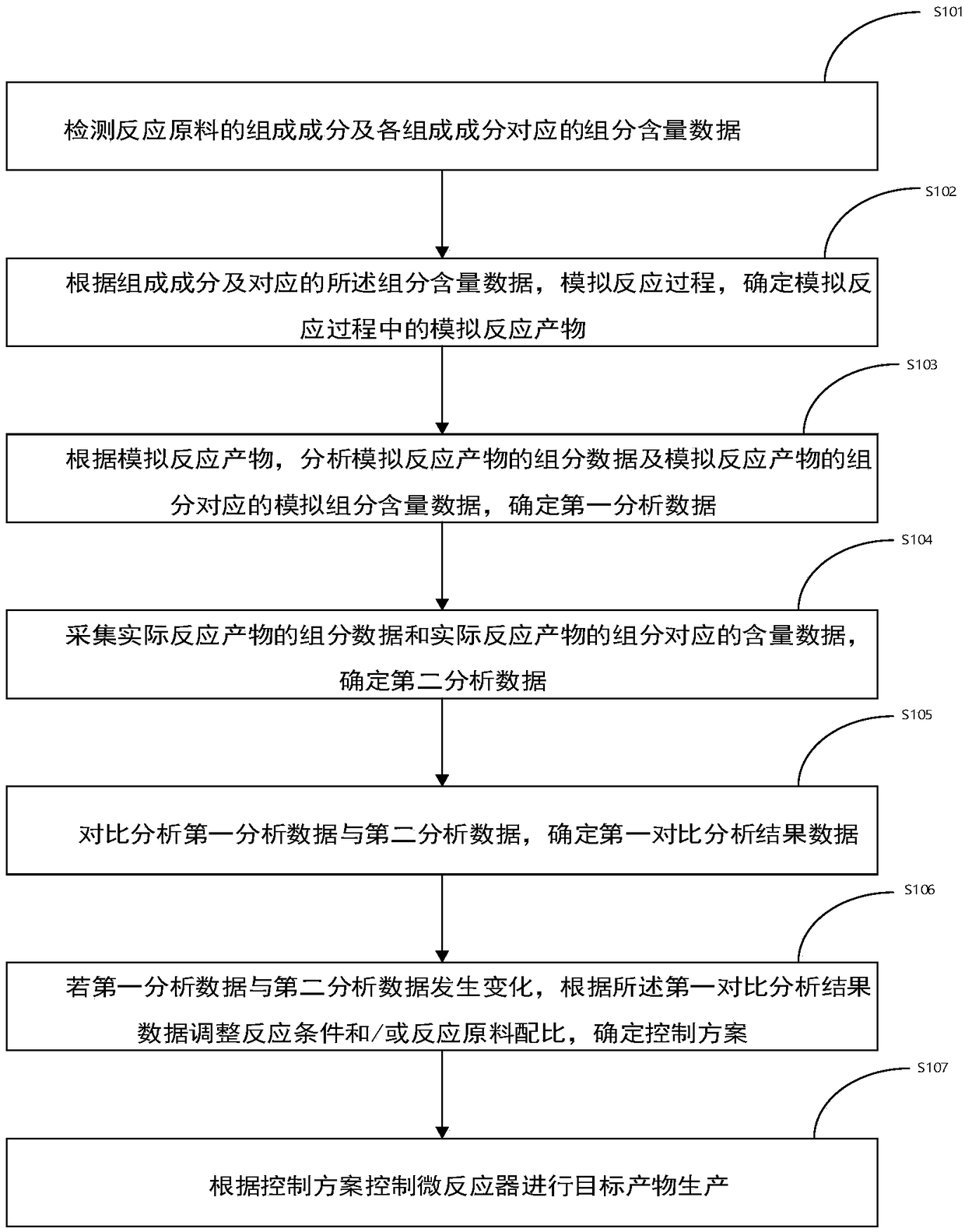

[0057] figure 1 It is a flow chart of a continuous flow production control method for a microreactor provided in an embodiment of the present invention, such as figure 1 As shown, the method in this embodiment may specifically include the following steps:

[0058] S101. Detect the components of the reaction raw materials and the component content data corresponding to each of the components;

[0059] Raw materials refer to raw materials that need to be reacted in chemical production, including liquid raw materials, solid raw materials, and gas raw materials. The reaction can be liquid and liquid reaction, liquid and solid reaction, or gas raw material and liquid raw material reaction. For the reaction of solid and liquid, the solid raw material is made into particles below 200 microns and then uniformly dispersed and suspended in the liquid phase and input into the reaction system. For the gas and liquid reaction, the interface of the gas and liquid mixing interface is spec...

Embodiment 2

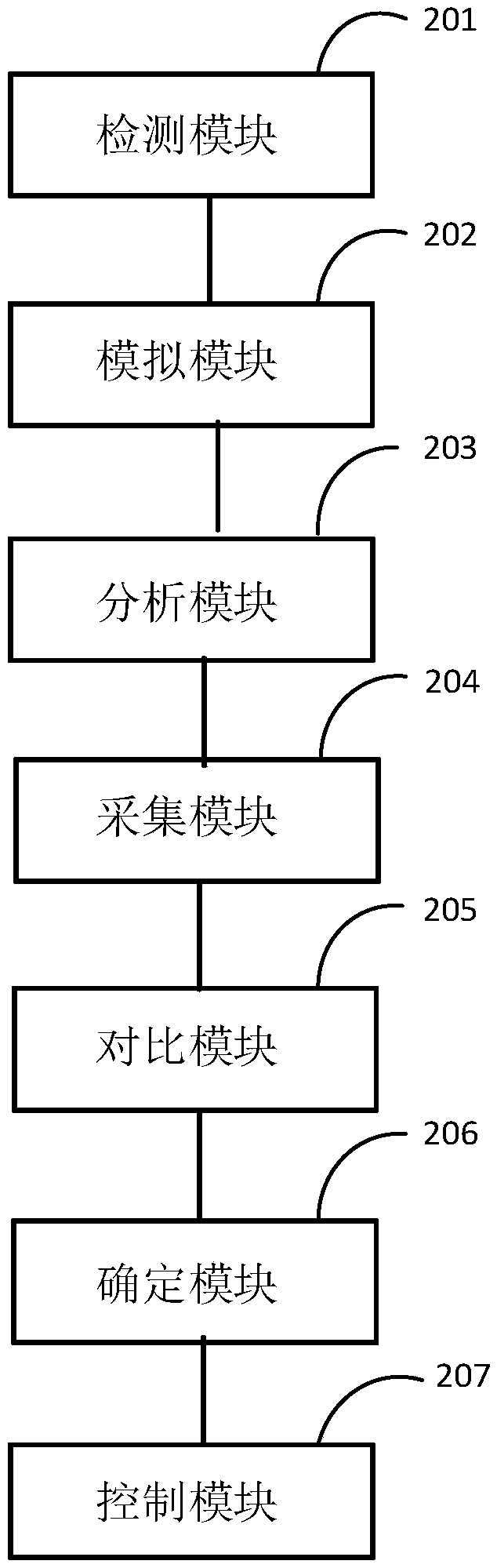

[0084] figure 2 It is a structural schematic diagram of a microreactor continuous flow production control device provided by the embodiment of the present invention. Such as figure 2 Shown, a kind of continuous flow production control device of microreactor comprises:

[0085] The detection module 201 is used to detect the components of the reaction raw materials and the component content data corresponding to each of the components;

[0086] The simulation module 202 is used to simulate the reaction process, and determine the simulated reaction product in the simulated reaction process;

[0087] An analysis module 203, configured to analyze the component data of the simulated reaction product and the simulated component content data corresponding to the components of the simulated reaction product, to determine the first analysis data;

[0088] The collection module 204 is used to collect the component data of the actual reaction product sample and the content data corre...

Embodiment 3

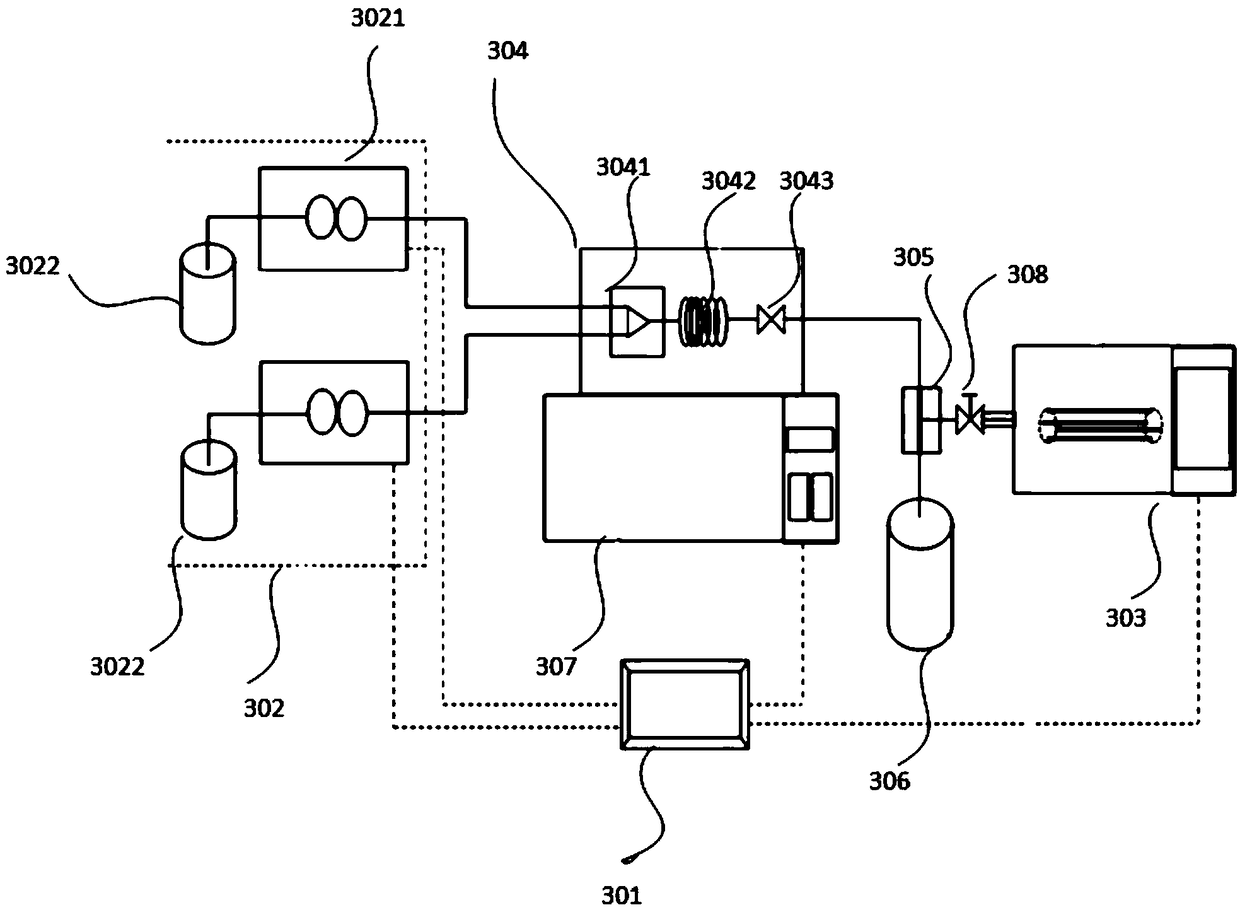

[0097] image 3 It is a structural schematic diagram of a microreactor continuous flow production control system. Such as image 3 As shown, a continuous flow production control system for a microreactor includes:

[0098] Control module 301, raw material input module 302, online mass spectrometer 303, microreactor module 304, microfluidic chip 305, product collection device 306;

[0099] The raw material input module communication end of the control module 301 is connected to the communication end of the raw material input module 302, and is used to detect the components of the reaction raw materials of the raw material input module 302 and the component content data corresponding to each of the components;

[0100] Optionally, the control module 301 can adopt an industrial control computer, and the simulation calculation model program is written in the industrial control computer, and has at least two communication terminals, which are respectively the communication termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com