Automatic knotting binding apparatus for finite length fibers and binding method using same

An automatic knotting and binding machine technology, which is applied in the direction of binding, transportation and packaging, and delivery of filamentous materials, to achieve the effect of increasing manufacturing speed and minimizing quality deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

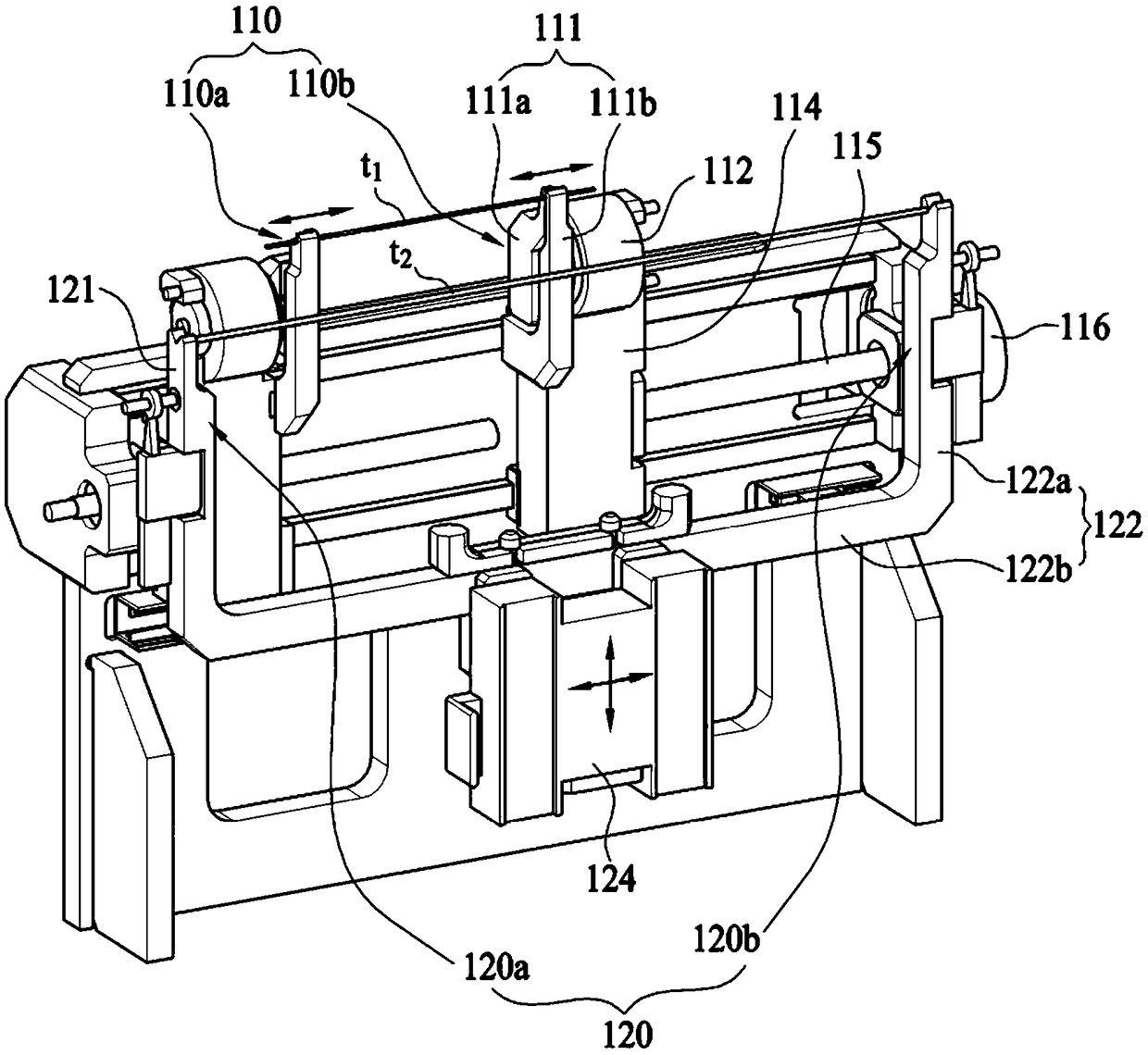

[0048] Preferred embodiments of the present invention that can specifically achieve the object of the present invention will be described below with reference to the accompanying drawings. In describing the present invention, the same names and the same reference numerals are used for the same configurations, and additional description thereof will be omitted.

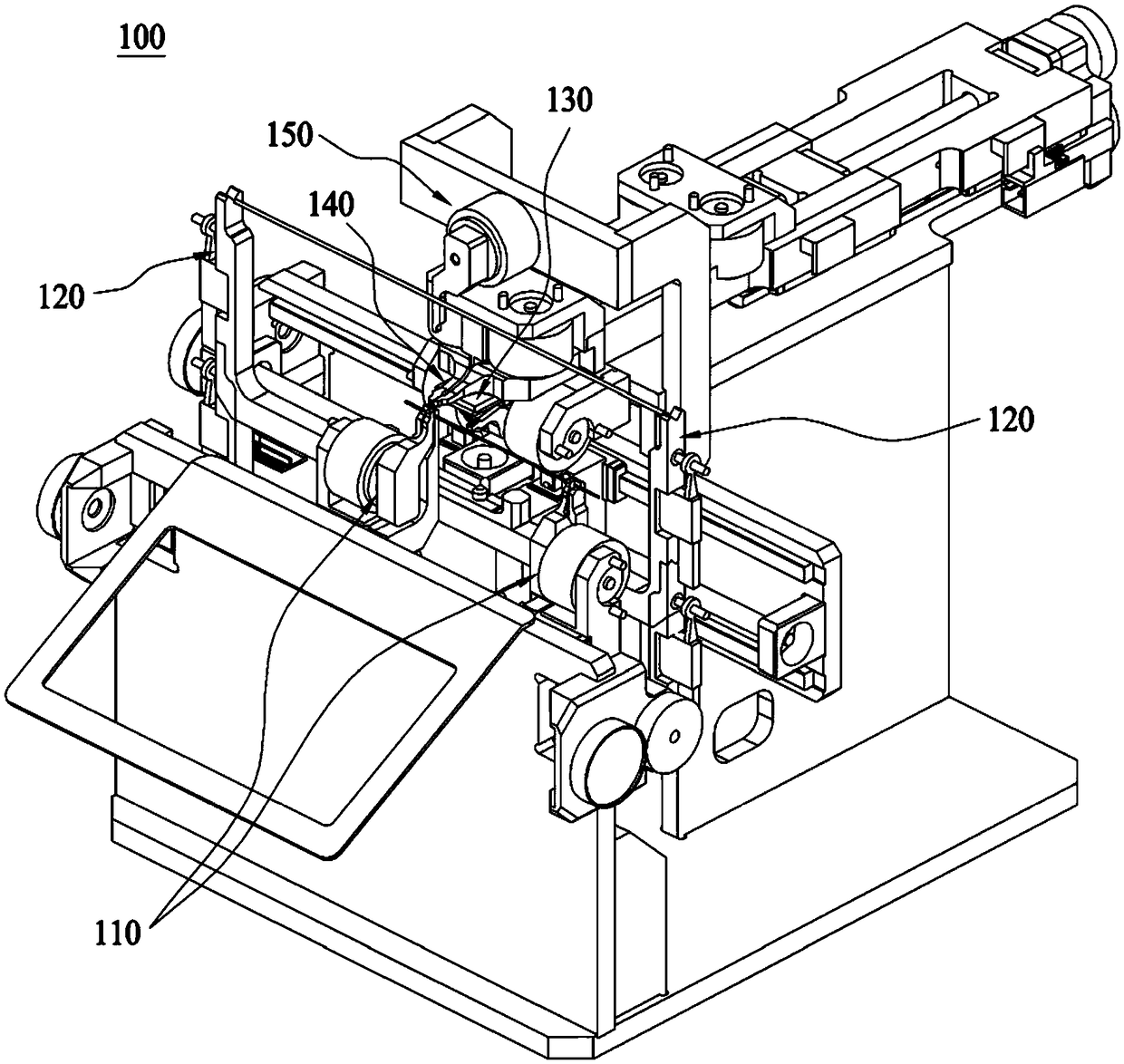

[0049] figure 1 It is a schematic diagram showing the overall form of an automatic knot-tying and binding machine 100 for finite-length fibers according to an embodiment of the present invention.

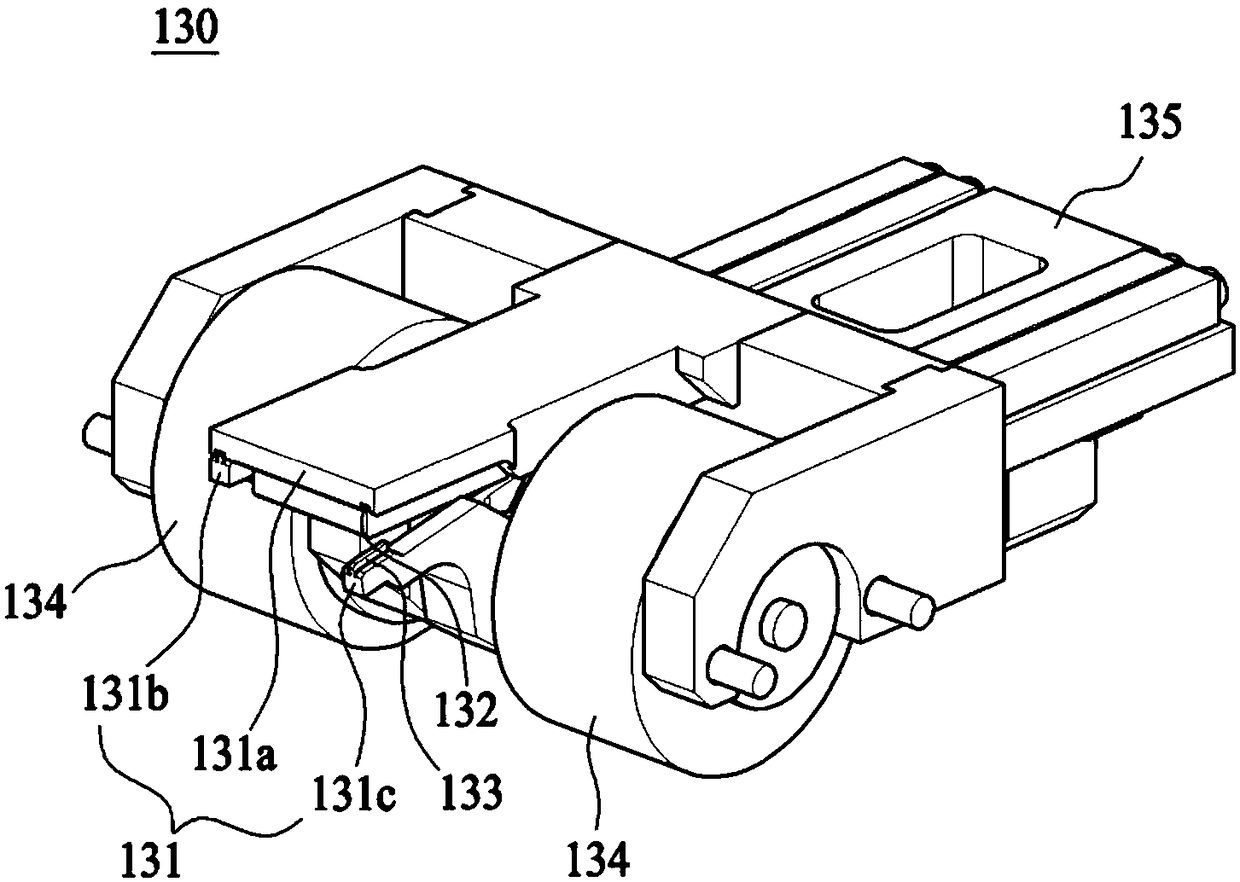

[0050] Such as figure 1 As shown, an automatic knotting and binding machine 100 for finite length fibers according to an embodiment of the present invention includes a first configuration component 110, a second configuration component 120, a first binding component 130, a second binding component 140 and a raw silk configuration component 150 .

[0051] The present invention can automatically bind a plurality of fibers hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com