Heavy oil emulsifying viscosity reducer and preparation method thereof

A technology for emulsifying and reducing viscosity and heavy oil, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult demulsification of heavy oil, increased equipment load, difficulty in natural dehydration, etc. The effect of reducing friction and excellent salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

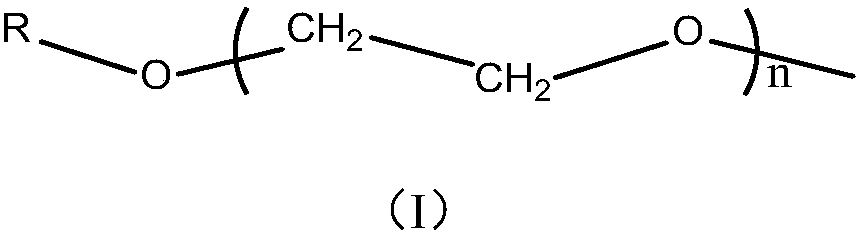

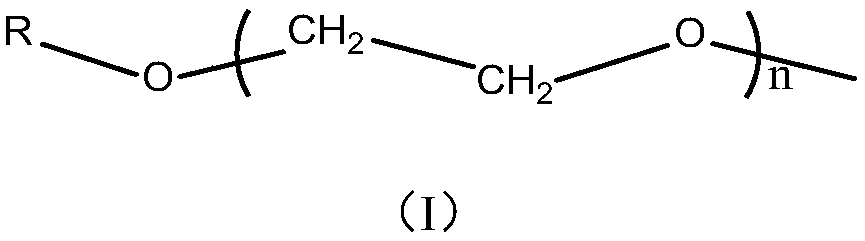

Image

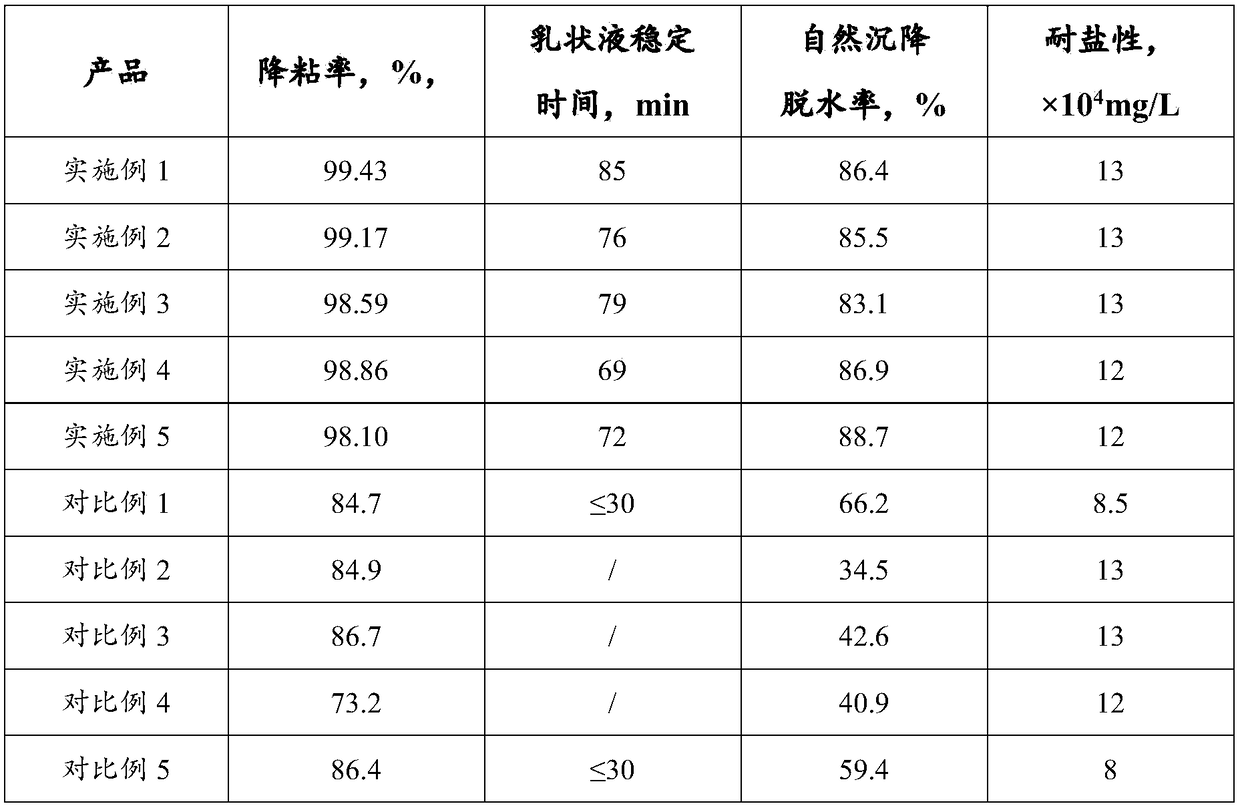

Examples

Embodiment 1

[0042] Take 6 parts of octylphenol polyoxyethylene ether, 5 parts of fatty alcohol polyoxyethylene ether and 70 parts of water into the flask, then stir the system and gradually raise the temperature to 60°C, and continue to stir until a uniform mixture is formed; Add 2 parts of sodium α-olefin sulfonate, 3 parts of sodium fatty alcohol polyoxyethylene ether sulfate, and 2.5 parts of formaldehyde solution into the above solution, continue stirring and dissolving to obtain a viscous oil emulsified viscosity reducer.

Embodiment 2

[0044] Take 6 parts of octylphenol polyoxyethylene ether, 5 parts of fatty alcohol polyoxyethylene ether and 70 parts of water into the flask, then stir the system and gradually raise the temperature to 60°C, and continue to stir until a uniform mixture is formed; Add 2 parts of sodium α-olefin sulfonate, 3 parts of sodium fatty alcohol polyoxyethylene ether sulfate, and 4 parts of formaldehyde solution into the above solution, continue stirring and dissolving to obtain a viscous oil emulsified viscosity reducer.

Embodiment 3

[0046] Take 6 parts of octylphenol polyoxyethylene ether, 5 parts of fatty alcohol polyoxyethylene ether and 75 parts of water into the flask, then stir the system and gradually raise the temperature to 60°C, and continue to stir until a uniform mixture is formed; Add 2 parts of sodium α-olefin sulfonate, 3 parts of sodium fatty alcohol polyoxyethylene ether sulfate, and 2.5 parts of formaldehyde solution into the above solution, continue stirring and dissolving to obtain a viscous oil emulsified viscosity reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com