Water-soluble nano material and preparation method and application thereof

A nanomaterial, water-soluble technology, applied in the field of nanomaterials, can solve the problems of low activity of nanometer viscosity reducer, unfriendly environment, difficult application, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare water-soluble nanomaterials, the steps are as follows:

[0040] Step (1) self-made double bond modified nano-SiO 2 Dilute with deionized water and perform magnetic stirring to obtain a nanomaterial dispersion with a nanomaterial concentration of 5 mg / ml;

[0041] Step (2) Weigh 15g of sodium a-olefin sulfonate, 9g of acrylamide and 6g of octadecyldimethylallyl ammonium chloride and dissolve them in 59.5 g of water to obtain a monomer mixed solution. Prepare 5 g of a solution containing 0.225 g of potassium persulfate and 5 g of a solution containing 0.075 g of sodium bisulfite.

[0042] Step (3) Slowly add the nanomaterial dispersion in step (1) to the monomer mixed solution in step (2), pour it into a three-necked round bottom flask, and place it in an oil bath;

[0043] Step (4) Set the temperature of the oil bath at 60° C., and pass nitrogen to carry out oxygen removal, and the oxygen removal time is > 30 minutes.

[0044] Step (5) After rising to the set ...

Embodiment 2

[0047] Prepare water-soluble nanomaterials, the steps are as follows:

[0048] Step (1) Dilute the purchased double-bond modified nano-montmorillonite with deionized water, and perform magnetic stirring to obtain a nano-material concentration of 1 mg / ml nano-material dispersion;

[0049] Step (2) Weigh 5 g of sodium α-olefin sulfonate, 3 g of acrylamide and 2 g of dodecyldimethylallyl ammonium chloride and dissolve them in 79.9 g of water to obtain a monomer mixed solution. Prepare 5 g of ammonium persulfate solution containing 0.04 g and 5 g of solution containing 0.01 sodium sulfite.

[0050] Step (3) Slowly add the nanomaterial dispersion in step (1) to the monomer mixed solution in step (2), pour it into a three-necked round bottom flask, and place it in an oil bath;

[0051] Step (4) Set the temperature of the oil bath at 40° C., and pass nitrogen gas to carry out oxygen removal, and the oxygen removal time is >30 minutes.

[0052] Step (5) After rising to the set tempe...

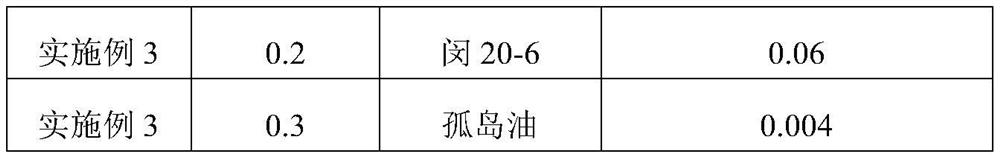

Embodiment 3

[0055] Prepare water-soluble nanomaterials, comprising the steps of:

[0056] Step (1) Dilute the purchased nanometer graphene oxide with deionized water, and carry out magnetic stirring to obtain a nanomaterial concentration of 3mg / ml nanomaterial dispersion;

[0057] Step (2) Weigh 10 g of sodium α-olefin sulfonate, 6 g of acrylic acid and 4 g of dodecyl dimethyl allyl ammonium chloride and mix them in 79.7 g of water to obtain a monomer mixed solution. Prepare 5 g of a solution containing 0.016 g of tert-butyl hydroperoxide and 5 g of a solution containing 0.004 g of ferric sulfite.

[0058] Step (3) Slowly add the nanomaterial dispersion in step (1) to the monomer mixed solution in step (2), pour it into a three-necked round bottom flask, and place it in an oil bath;

[0059] Step (4) Set the temperature of the oil bath at 50° C., and pass nitrogen to carry out deoxygenation, and the deoxygenation time is > 30 minutes.

[0060] Step (5) After rising to the set temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com