A preparation method of silver-gold alloy bonding wire with high strength and toughness and low resistivity

A low-resistivity, silver-gold alloy technology, applied in the field of alloys, can solve the problems of low strength and high price, achieve the effect of improving the yield, reducing volatilization loss, and ensuring uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

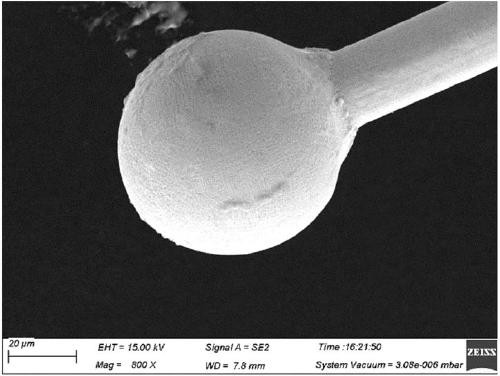

Image

Examples

Embodiment 1

[0033] Example 1: Ag content is 99.4%, Ce content is 0.005%, Cu content is 0.001%, and the rest is Au;

Embodiment 2

[0034] Example 2: Ag content is 85%, Ce content is 0.01%, Cu content is 0.05%, Pd content is 0.01%, Ca content is 0.0005%, and the rest is Au;

Embodiment 3

[0035] Embodiment 3: the Ag content is 95%, the Ce content is 0.005%, the Cu content is 0.005%, the Be content is 0.005%, and the rest is Au;

[0036] The above-mentioned gold purity is ≥99.995% high-purity gold, the silver purity is ≥99.999% high-purity silver, and the purity of other elements is ≥99.99%.

[0037] Get each component described in embodiment 1-3, prepare the silver-gold alloy bonding wire of high strength toughness, low resistivity respectively according to the following method:

[0038] 1) High vacuum medium frequency induction melting:

[0039] Put Au and part of Ag (the amount of Ag is not more than half of the total amount of Ag) in a high-vacuum medium-frequency melting furnace for master alloy melting, the melting temperature is 1100-1300 ° C, and the melting process is filled with high-purity Protected by argon gas, after refining and cooling for 10-30 minutes, alloy ingots are obtained; processed into Ag / Au master alloy plates, cleaned and ready for us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com