Anti-corrosion method of offshore wind power foundation steel piles

A technology for offshore wind power and steel piles, which is applied in the anticorrosion field of foundation steel piles. It can solve the problems of not being able to work directly underwater, long installation period, and large limitations, and achieve the effects of preventing ocean adhesion erosion, fast construction, and short cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

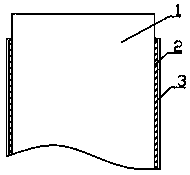

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] The anti-corrosion method for offshore wind power foundation steel piles comprises the following steps,

[0036] S1: Surface treatment of steel piles: use a shovel or high-pressure spray gun to treat the surface of steel piles; the rust removal grade can be slightly lower than the current national standard "Steel surface corrosion grade and rust removal grade before painting" (GB / T8923) The St2 level. If the conditions are limited, at least the visible grease, dirt and marine organisms on the surface should be removed, and there should be no attachments such as scale, rust, paint, and coating that are not firmly attached; special attention should be paid to the quality of rust removal at nodes;

[0037] S2: Viscoelastic anti-corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com