Automatic protection device for discharge outlet of discharge platform

An unloading platform, automatic protection technology, applied in the processing of building materials, construction, building structure, etc., can solve problems such as unsatisfactory practicality and economic angle, unreasonable overall structure, etc., and achieve significant safety of life and property. , the effect of overcoming potential safety hazards and valuable market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

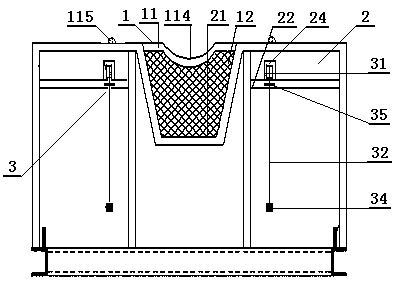

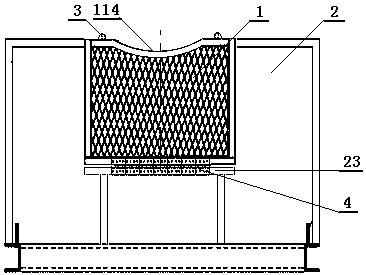

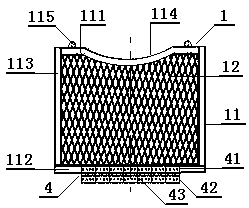

[0030] exist Figure 1-Figure 4 Among them, an automatic protection device for the discharge port of the unloading platform of the present invention, the main body includes a baffle 1, a platform side plate 2, a limit traction assembly 3 and a hinge 4, and the feature is that the baffle 1 has an overall covering The function of the trapezoidal discharge opening includes the peripheral frame 11 and the middle main board 12. The platform side plate 2 includes an inverted trapezoidal discharge opening 21, a square steel skeleton 22, a hinge mounting plate or square steel 23, and a wire rope threading Holes 24, the limiting traction member 3 has the function of limiting and deflecting the traction baffle 1, including a pulley 31, a wire rope 32, a wire rope clip 33, a counterweight 34, and a limiting device 35, and the hinge 4 has The function of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com