Downward drilling plugging-while-drilling type slag discharging device and method

A technology while drilling, drill pipe, applied in earth-moving drilling, sealing/packing, wellbore/well components, etc., can solve the problem of difficulty in reaching slag discharge pressure, inability to guarantee slag discharge power, and slag discharge power steep drop, etc. problem, to achieve the effect of low input cost, good economic and social benefits, and stable slag discharge power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

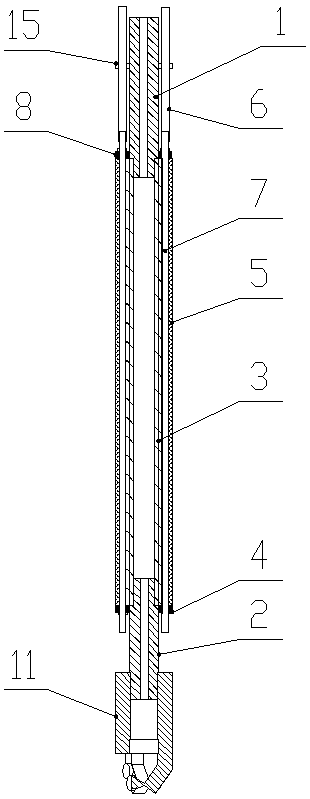

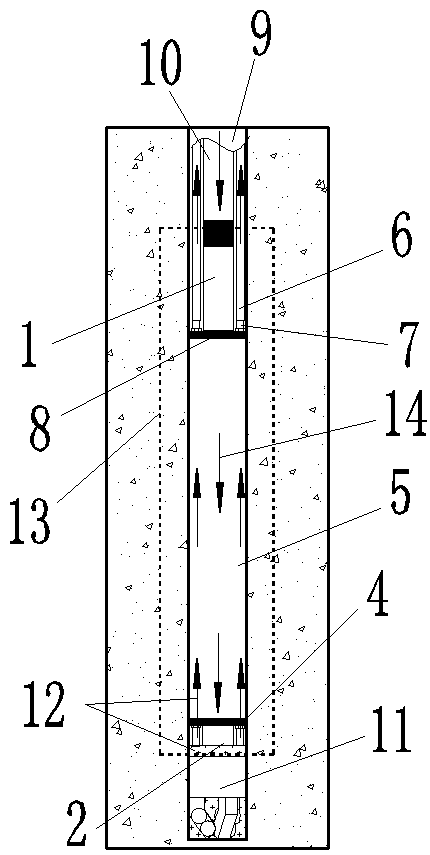

[0025] As pictured and figure 2 As shown, the down-drilling plugging type slag discharge device of the present invention includes an upper hollow connecting rod 1, a lower hollow connecting rod 2, a sealed bearing 3, a sealing rubber ring 5, and an upper slag discharging device arranged vertically. Conduit 6 and lower slag discharge conduit 7;

[0026] The lower end of the upper hollow connecting rod 1 extends into and is threaded into the upper port of the inner ring of the sealed bearing 3, and the upper end of the lower hollow connecting rod 2 extends into and is threaded into the lower port of the inner ring of the sealed bearing 3 to seal the rubber ring 5 sets are arranged on the outer ring of the sealed bearing 3, and the outer ring of the sealed bearing 3 is provided with two inner semicircular long grooves which are transparent up and down along the axial direction. The transparent outer semicircular long groove, two inner semicircular long grooves and two outer sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com