An explosion-proof film capacitor which prevents electric breakdown between pole shells

An explosion-proof film and capacitor technology, applied in the direction of film/thick film capacitors, laminated capacitors, wire wound capacitors, etc., can solve the problems of unqualified withstand voltage of the pole shell, easy falling off of metal particles, electrical breakdown of the electrode and its shell, etc. , to achieve the effects of improving the withstand voltage pass rate, preventing electrical breakdown, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

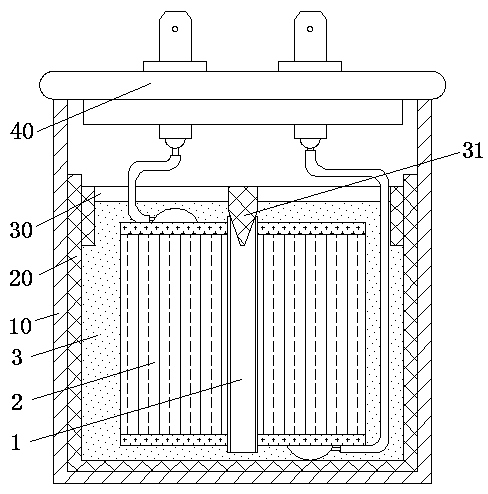

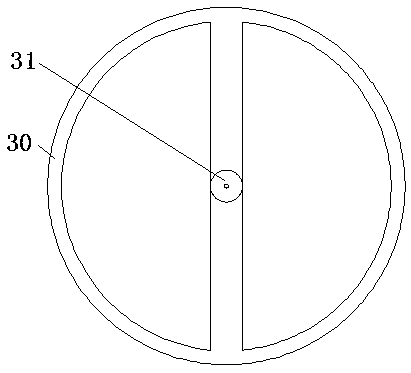

[0014] Such as Figure 1-2 As shown, the present invention is an explosion-proof film capacitor that prevents electrical breakdown between pole shells, comprising an aluminum casing (10), an explosion-proof cover plate assembly (40) and a capacitor body arranged in the aluminum casing (10); The capacitor body includes a lower positioning sleeve (20), an upper positioning cover (30) and a capacitor core (2) wound on the mandrel (1) arranged between the lower positioning sleeve (20) and the upper positioning cover (30). ); the outer diameter of the upper positioning cover (30) is less than the inner diameter of the lower positioning sleeve (20) 1mm, which is convenient for core assembly; the capacitor core (2), the lower positioning sleeve (20), and the upper positioning cover (30) Pouring with impregnating agent (3).

[0015] The outer diameter of the lower positioning sleeve (20) is less than or equal to the inner diameter of the aluminum casing (10), and when the capacitor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com