Surface interface passivation layer and passivation method of a kind of crystalline silicon solar cell

A technology of crystalline silicon solar cells and crystalline silicon cells, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of low growth rate, achieve reduced interface state density, excellent interface chemical passivation effect, and good field passivation The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

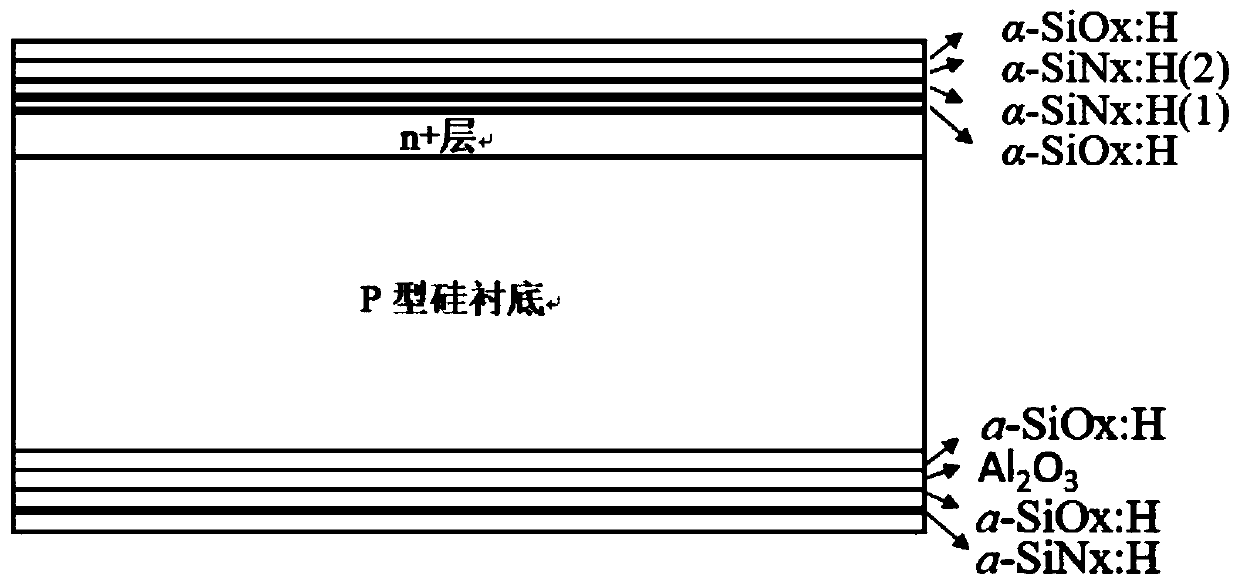

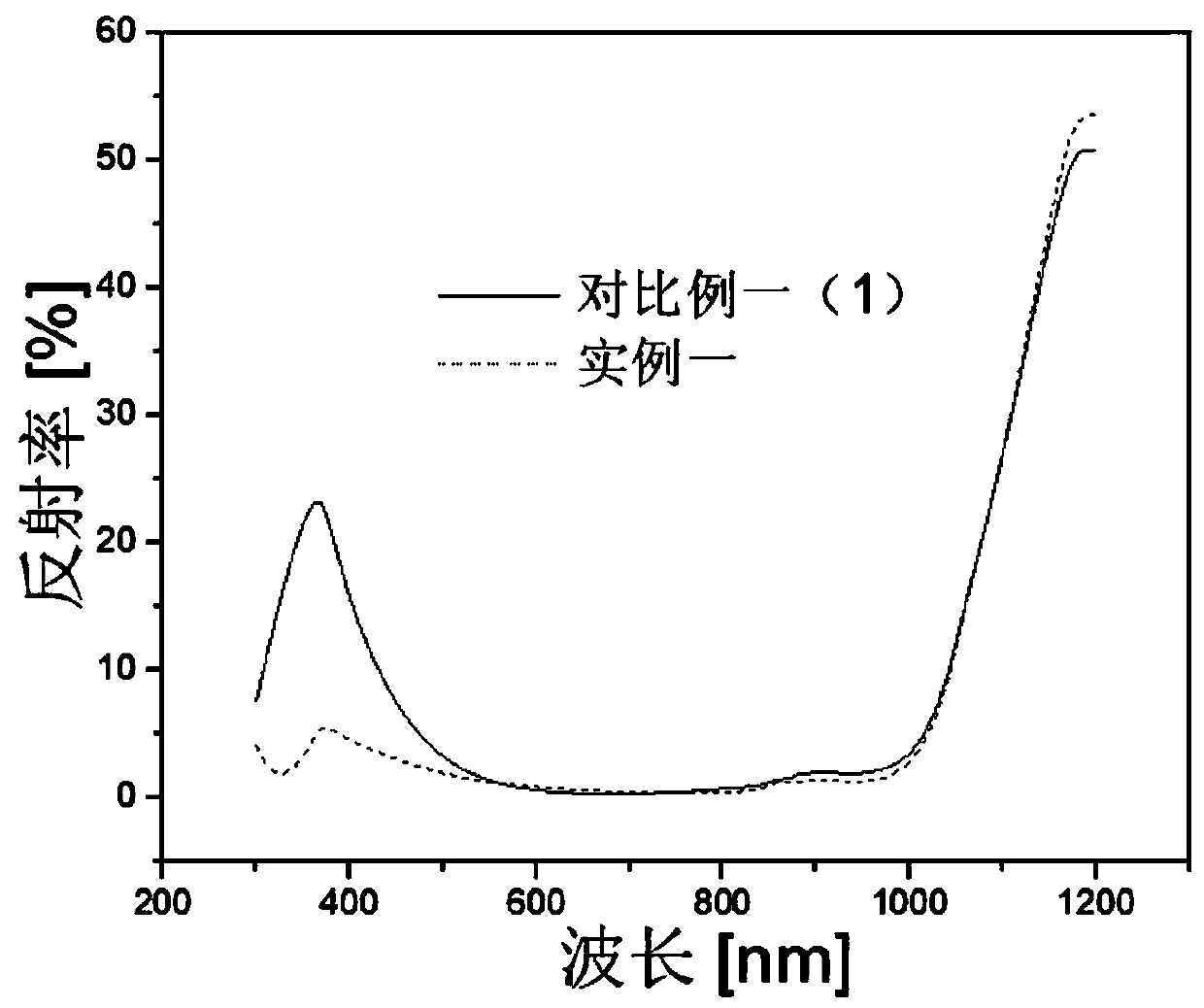

[0030] Example 1: n + α-SiOx:H / α-SiNx:H((refractive index 2.18) / α-SiNx:H(refractive index 2.08) / α-SiOx:H four-layer film passivation on the layer.

[0031] After cleaning the silicon wafer, insert it into the graphite boat, deposit α-SiOx:H layer in the PECVD tube, feed silane and laughing gas, the flow rate of silane is 90sccm, the flow rate of laughing gas is 3.7slm, the temperature is controlled at 450°C, and the pressure is 700mTorr. The power is 2100 watts, and the time is 15s; stop the laughing gas, and turn off the radio frequency source. Keep the temperature controlled at 450°C, increase the flow rate of silane to 500sccm, pass ammonia gas, the flow rate of ammonia gas is 3.8slm, the pressure is 1500mTorr, turn on the radio frequency source, set the radio frequency power to 1700 watts, and deposit the first layer of α-SiNx: H, the time is 550s; then grow the second layer of α-SiOx:H in the PECVD tube, pass ammonia gas, the flow rate of ammonia gas is 4.05slm, the pres...

example 2

[0039] Example 2: α-SiOx:H / Al on p-type layer 2 o 3 / SiOx / α-SiNx:H Quadruple Laminated Thin Film Passivation

[0040] After cleaning the silicon wafer, insert it into the graphite boat, deposit α-SiOx:H layer in the PECVD tube, feed silane and laughing gas, the flow rate of silane is 90sccm, the flow rate of laughing gas is 3.7slm, the temperature is controlled at 450°C, and the pressure is 700mTorr. The power is 2100 watts, and the time is 15s; after the end, the boat is released; it is automatically transferred from the cassette to the ALD chamber to deposit aluminum oxide film, the temperature is controlled at 200°C, and TMA and H 2 O, the flow rates are 10slm and 15slm respectively, and the deposition time is about 15s. After deposition, it is automatically transported out of the chamber and into the cassette. Then the silicon wafer is inserted into the graphite boat, and the second layer of α-SiOx:H layer is grown in the PECVD tube, and silane and laughing gas are intro...

example 3

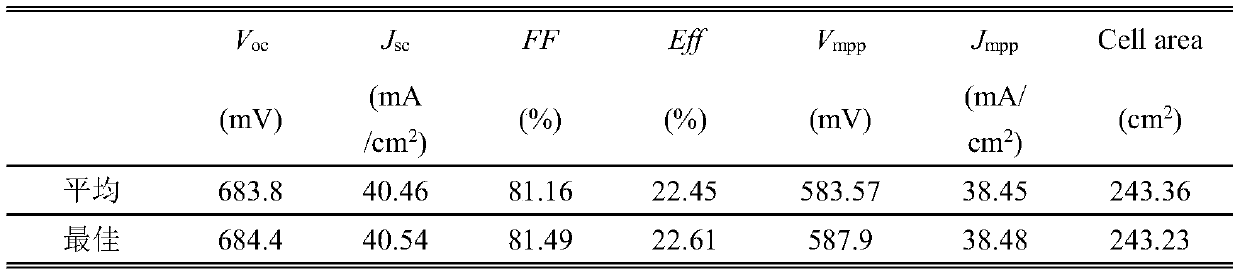

[0051] Example three: the n that embodiment one obtains + Type layer passivation film structure and the application of the p-type layer passivation film structure obtained in Example 2 in p-type PERC cells

[0052] Table 3 Application Effects in Example 3 p-type PERC

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com