Method and equipment for processing black tea containing high theaflavin by utilizing fresh summer-autumn tea leaves

A technology of theaflavin black tea and fresh tea leaves, which is applied in the directions of pre-extraction tea processing, food preservation, food science, etc., can solve the problem of limited population of black tea, achieve excellent product quality, optimize fermentation process parameters, and improve tea production. The effect of flavin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

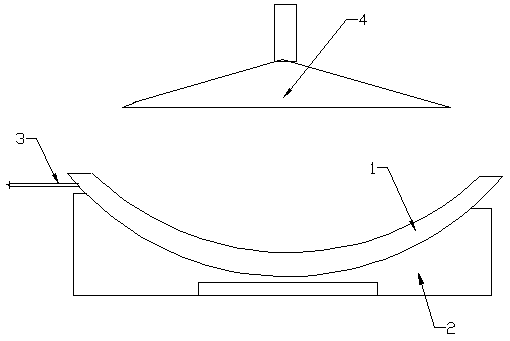

Image

Examples

Embodiment 1

[0020] The method for processing high theaflavin black tea from summer and autumn tea fresh leaves is realized through the processes of wilting, rolling, fermenting, drying, and preserving, specifically,

[0021] Among them, the withering is natural withering, that is, fresh leaves of summer tea or autumn tea with two leaves and one heart or three leaves and one heart are picked and placed outdoors on a sunny day, requiring good ventilation and avoiding direct sunlight. The thickness of the spread is 1-1.5cm. Dry in the sun until the leaves curl, turning once during the period;

[0022] Kneading and frying tea, that is, using the principle of light and heavy rolling, knead the withered tea leaves until the stems and leaves slowly overflow water, and you can feel soft and sticky when you touch it with your hands. Generally, knead for 20 minutes, and then put it into the wok for 60 minutes. Fry at 10°C for 15 minutes, spray the mixed aqueous solution of amino acid and reducing s...

Embodiment 2

[0028] The method for processing high theaflavin black tea from summer and autumn tea fresh leaves is realized through the processes of wilting, rolling, fermenting, drying, and preserving, specifically,

[0029] Among them, the withering is natural withering, that is, fresh leaves of summer tea or autumn tea with two leaves and one heart or three leaves and one heart are picked and placed outdoors on a sunny day, requiring good ventilation and avoiding direct sunlight. The thickness of the spread is 1-1.5cm. Dry in the sun until the leaves curl, flipping twice during the period;

[0030] Kneading and frying tea, that is, using the principle of light and heavy rolling, knead the withered tea leaves until the stems and leaves slowly overflow water, and you can feel soft and sticky when you touch it with your hands. Generally, knead for 30 minutes, and then put it into the wok for 50 minutes. Stir-fry at ℃ for 15-25min, spray the mixed aqueous solution of amino acid and reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com