Conjoined balanced-pressure continuous extraction device capable of controlling bubble size of air-assisted solvents

An extraction device and bubble technology, applied in solvent extraction, liquid solution solvent extraction, chemical instruments and methods, etc., can solve the problem of increasing the contact area between the extraction phase and the extracted phase, excessive pressure at the center point of the tower kettle, and reducing the amount of extraction agent and other problems, to achieve the effect of reducing the cost of stripping, increasing the contact area, and reducing the loss of extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

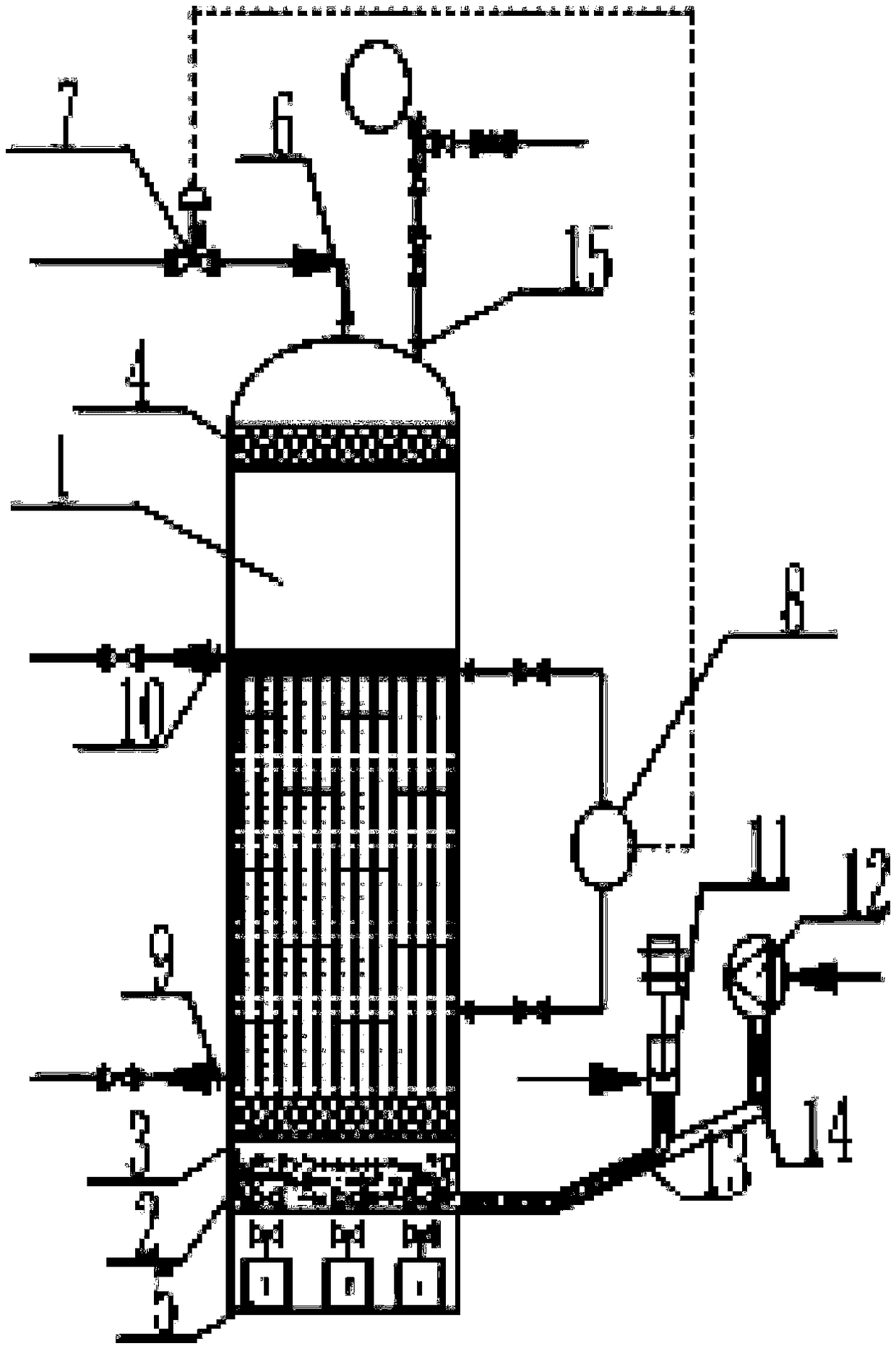

[0022] combined with figure 1 The operation flow of a continuous extraction device with one-piece pressure and controllable gas co-solvent bubble size is as follows:

[0023] The S1 solvent phase is pumped into the solvent phase inlet (14) through the solvent pump (12), and the solvent phase enters the gas-assisted solvent bubble regulator (2). Fill the gas cosolvent bubble regulator (2) with solvent phase.

[0024] The extracted phase of S2 is regulated by the regulating valve (7), filtered through the liquid phase filter plate (4) into the gas-assisted solvent bubble extractor (1), and the liquid phase is controlled by the liquid level gauge (8) to reach the upper line height of the liquid level.

[0025] S3 opens the magnetic stirrer (5), the gas phase is pumped into the gas phase inlet (13) through the gas pump (11), opens the inspection vent (15), checks to ensure that the gas runs smoothly in the extraction reactor, and the solvent phase passes through the solvent pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com