Heat treatment method for correcting plane warping deformation of injection molded product

A heat treatment method and injection molding technology, applied in the field of injection molding, can solve the problems of warping and deformation of plastic products, affecting the normal use of plastic products, and adversely affecting the test results, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0014] A heat treatment method for correcting plane warping deformation of injection molded products includes two parts: a correction tool and a correction process.

[0015] The material of the injection molded product in this example is some kind of polypropylene. The bottom plane of the product is 100mm long and 80mm wide. It has a complex structure with a maximum height of 9mm and a wall thickness of 1.3mm. 0.42mm.

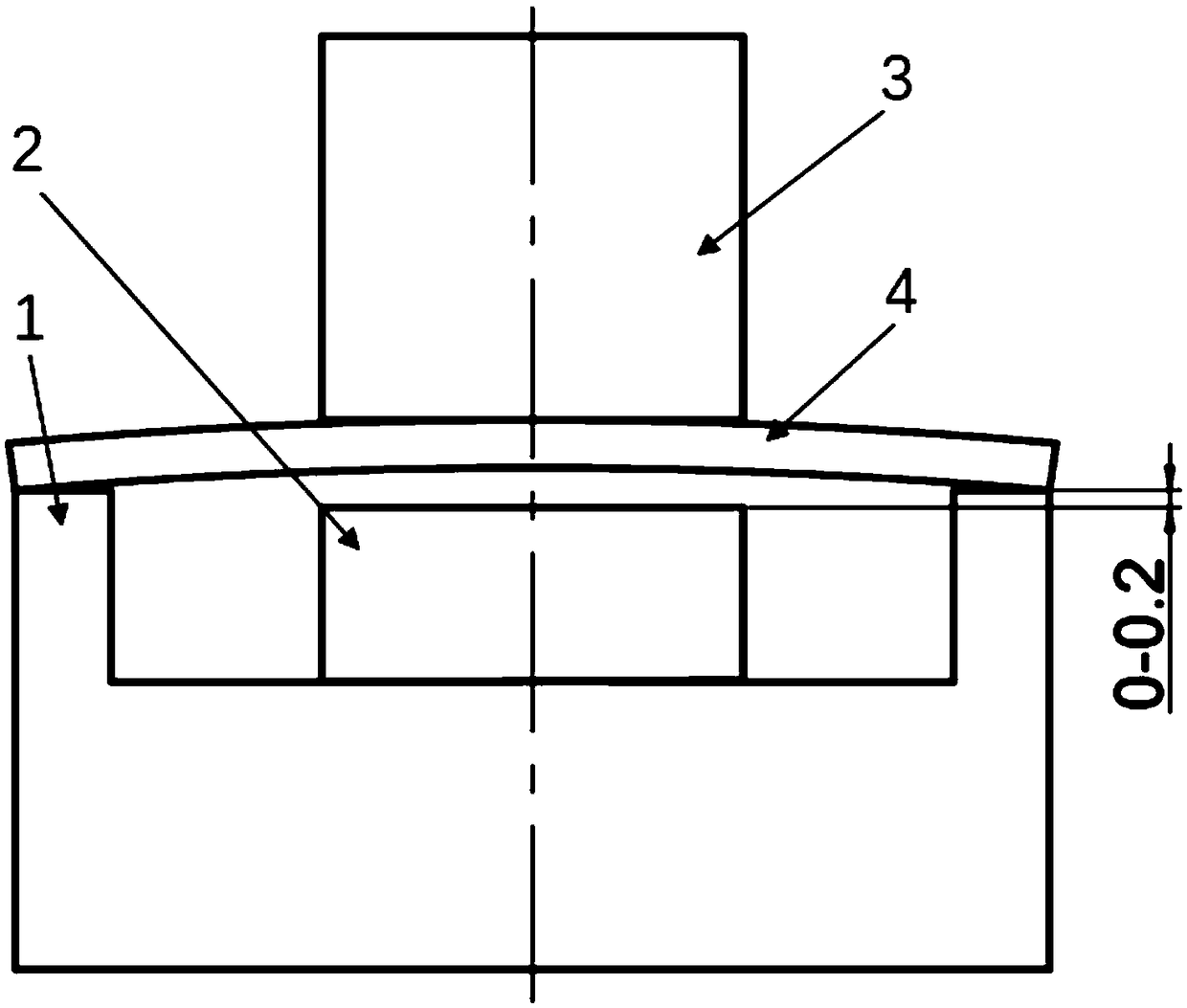

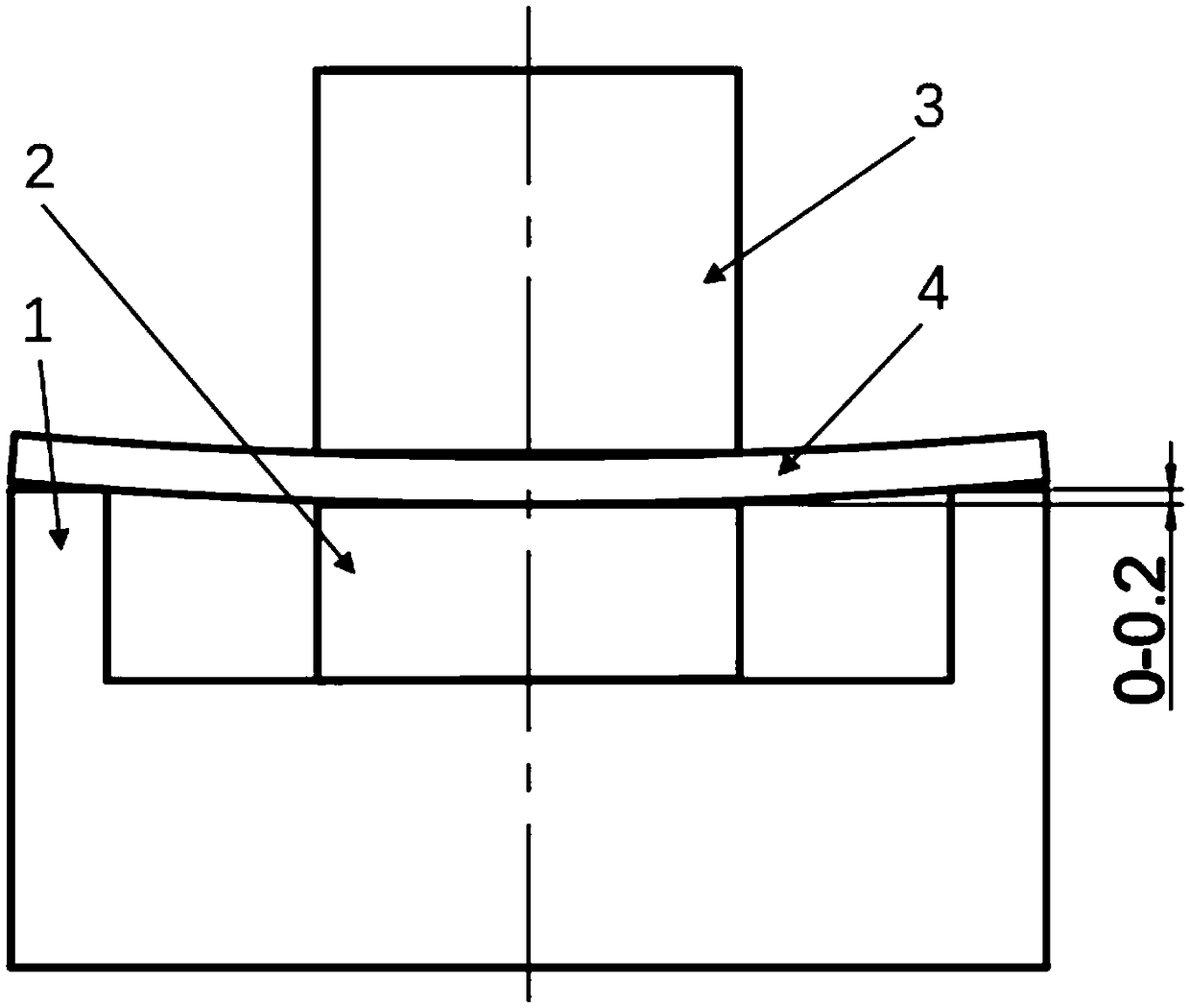

[0016] Such as figure 1 As shown, the overall width of the U-shaped correction bracket 1 is set to 100mm, and the span is set to 80mm; The height of both ends is 0.1mm lower; the length of the pressing block 3 is set to 80mm, and the width and thickness are equal to the width of the adjusting block 2, which is set to 40mm.

[0017] According to the material of the injection molded product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com