Method for 3D printing by utilizing multi-wavelength light

A 3D printing, multi-wavelength technology, applied in the direction of 3D object support structure, additive manufacturing, processing and manufacturing, etc., can solve the problems of increased printing cost, large optical and mechanical loss, etc., to achieve improved service life, low energy requirements, and reduced manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

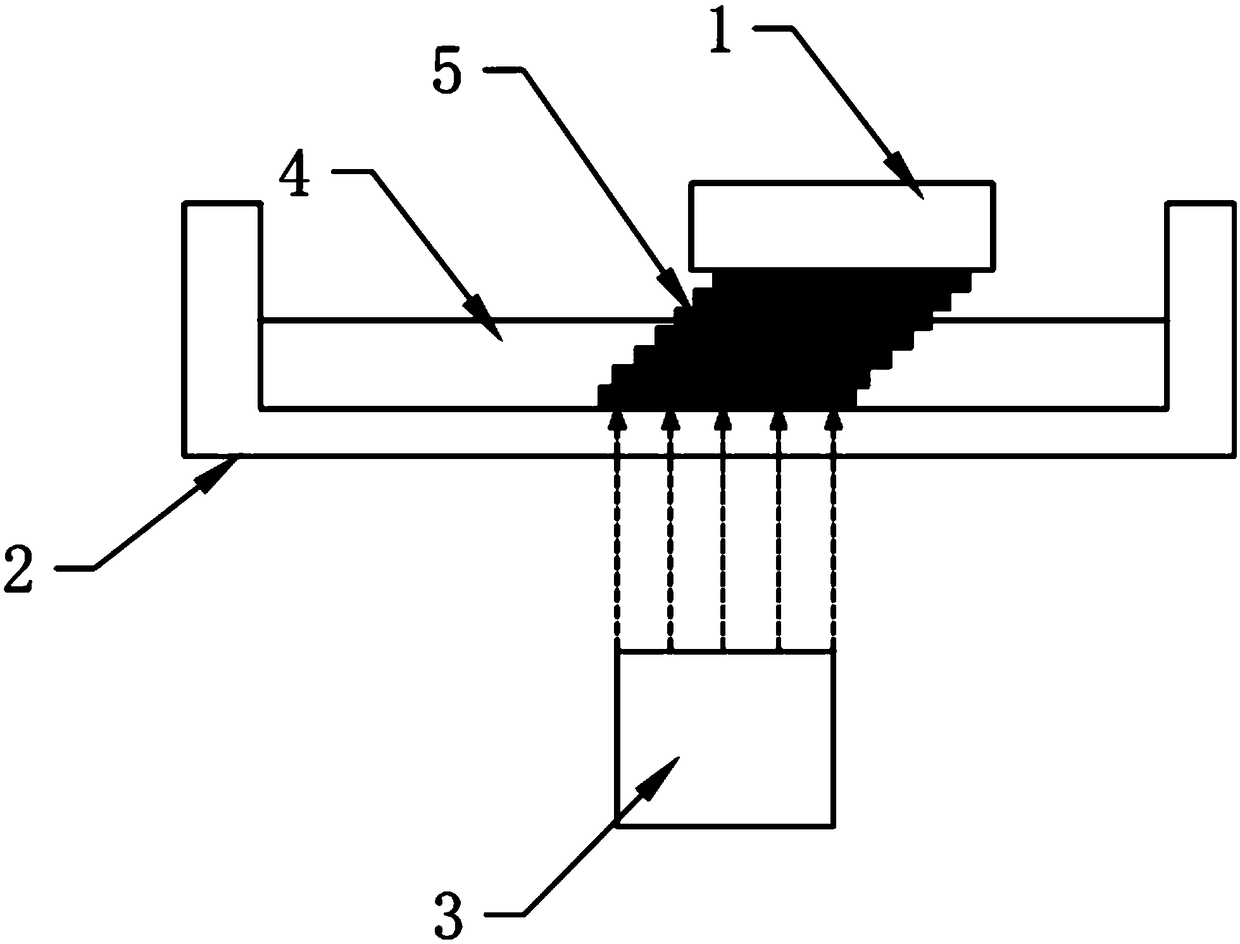

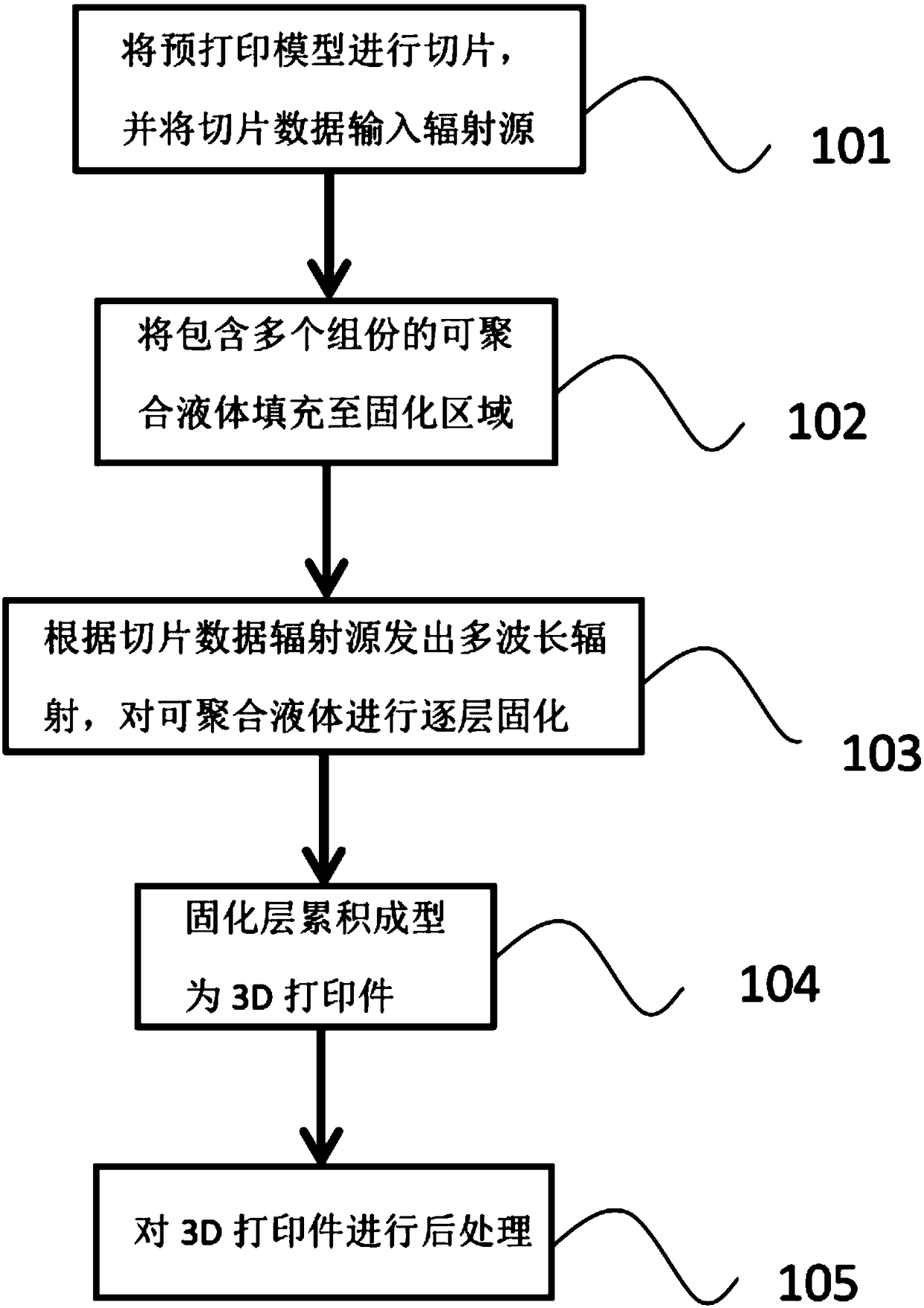

[0041] Use light-curing 3D printing equipment to perform multi-wavelength 3D printing according to the above steps, wherein the radiation source 3 is an optical machine, and the light source of the optical machine includes bulb 1 and bulb 2. Bulb 1 provides light with a wavelength of 200-300nm, and bulb 2 provides light with a wavelength Illumination of 350-450nm; the polymerizable liquid 4 includes two mixed components, which can be polymerized and cured under 200-300nm and 350-450nm wavelength light irradiation respectively.

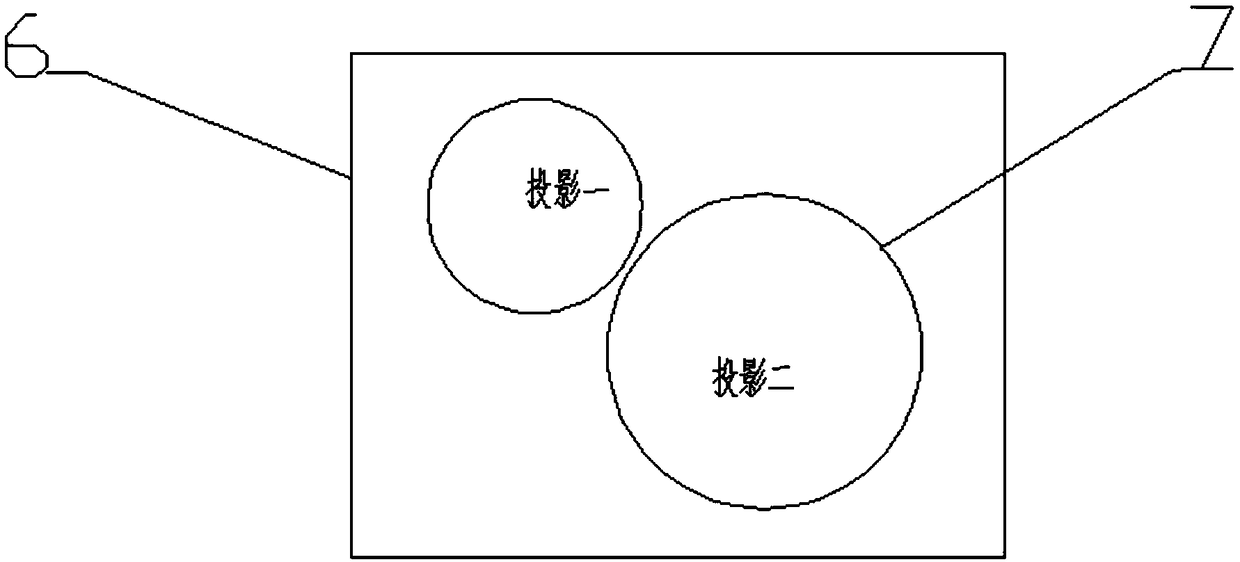

[0042] The lights of different wavelengths emitted by the light machine during the 3D printing process are projected onto the light-curing molding surface 6 without overlapping each other. The projection of light emitted by bulb 1 is projection 1, and the projection of light emitted by bulb 2 is projection 2. For example, image 3 As shown, the radiation range 7 of the radiation source is projected on the light-curing molding surface 6, wherein the proj...

Embodiment 2

[0044] Use light-curing 3D printing equipment to perform multi-wavelength 3D printing according to the above steps, wherein the radiation source 3 is an optical machine, and the light source of the optical machine includes bulb 1 and bulb 2. Bulb 1 provides light with a wavelength of 200-300nm, and bulb 2 provides light with a wavelength Illumination of 350-450nm; the polymerizable liquid 4 includes two mixed components, which can be polymerized and cured under 200-300nm and 350-450nm wavelength light irradiation respectively.

[0045] The lights of different wavelengths emitted by the light machine during the 3D printing process are projected onto the light-curing molding surface 6 and partially overlapped. The projection of light emitted by bulb 1 is projection 1, and the projection of light emitted by bulb 2 is projection 2, as shown in Figure 4 As shown, the radiation range 7 of the radiation source is projected on the photocuring molding surface 6, wherein the first proje...

Embodiment 3

[0047] Use light-curing 3D printing equipment to perform multi-wavelength 3D printing according to the above steps, wherein the radiation source 3 is an optical machine, and the light source of the optical machine includes bulb 1 and bulb 2. Bulb 1 provides light with a wavelength of 200-300nm, and bulb 2 provides light with a wavelength Illumination of 350-450nm; the polymerizable liquid 4 includes two mixed components, which can be polymerized and cured under 200-300nm and 350-450nm wavelength light irradiation respectively.

[0048] The lights of different wavelengths emitted by the light machine during the 3D printing process are projected onto the light-curing molding surface 6 to completely overlap, the projection of the light emitted by bulb 1 is projection 1, and the projection of light emitted by bulb 2 is projection 2, for example Figure 5 As shown, the radiation range 7 of the radiation source is projected on the photocuring molding surface 6, wherein the projection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com