Temperature-resistant tpu light conveyor belt and manufacturing method thereof

A light conveyor belt, temperature-resistant technology, applied in the field of conveyor belt manufacturing, can solve the problems of easy aging failure of the adhesive layer, carbonization and disintegration, separation of TPU surface layer and skeleton material, etc., to avoid aging cracking, add less, increase The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

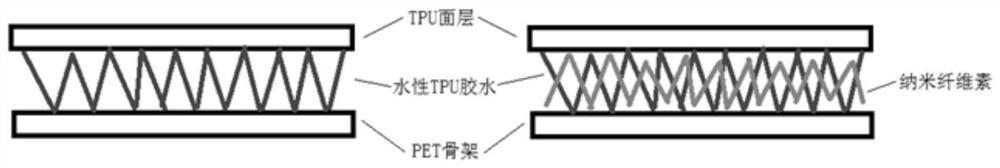

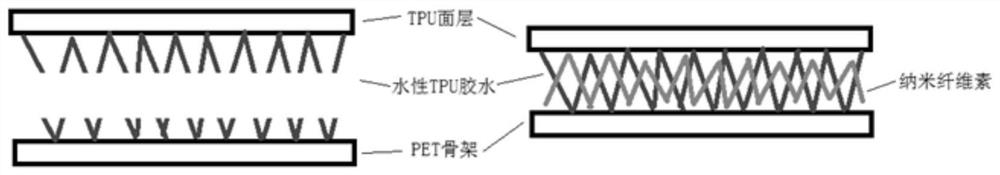

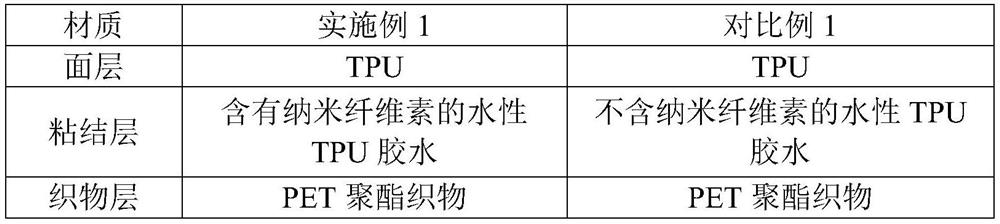

[0029] According to the structure and material in Table 1, prepare a light-duty heat-resistant TPU conveyor belt; add 10% nanocellulose and 5% curing agent to the water-based TPU glue, and stir for 15min at a stirring speed of 500r / min; One side of the ester fabric layer is coated with the above-mentioned mixed glue, and the coating amount is 100g / m 2 , dried in an infrared heating oven at 100°C; then the dried composite layer coated with glue is bonded to the TPU surface layer, extruded and calendered at an extrusion temperature of 185°C and an extrusion pressure of 10Pa, and cooled That is to say; the cloth surface temperature of the fabric layer is 125° C. during the extrusion and calendering compounding process.

Embodiment 2

[0035] The manufacturing method of the temperature-resistant TPU light conveyor belt is: add 10% nanocellulose and 5% curing agent to the water-based TPU glue, stir for 10 minutes at a stirring speed of 400r / min; The surface is coated with mixed glue, and the coating amount is 80g / m 2 , dried in an infrared heating oven at 100°C; then the dried composite layer coated with glue is bonded to the TPU surface layer, extruded and calendered at an extrusion temperature of 180°C and an extrusion pressure of 10Pa, and cooled That is to say; the fabric surface temperature of the PET polyester fabric layer is 120° C. during the extrusion calendering compounding process.

Embodiment 3

[0037] The manufacturing method of the temperature-resistant TPU light conveyor belt is as follows: add 10% nanocellulose and 5% curing agent to the water-based TPU glue, stir for 20 minutes at a stirring speed of 600r / min; The surface is coated with mixed glue, and the coating amount is 120g / m 2 , dried in an infrared heating oven at 120°C; then the dried composite layer coated with glue is bonded to the TPU surface layer, extruded and calendered at an extrusion temperature of 190°C and an extrusion pressure of 15Pa, and cooled That is to say; the cloth surface temperature of the fabric layer is 130° C. during the extrusion and calendering compounding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com