Preparation method of translucent paper with graphics and translucent paper with graphics

A technology for translucent paper, graphics and text, applied in papermaking, paper, patterned paper, etc., can solve the problems of complex preparation process, not meeting food-grade requirements, etc., achieve screen mesh optimization, save printing process, and print pattern outline. Clarity clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

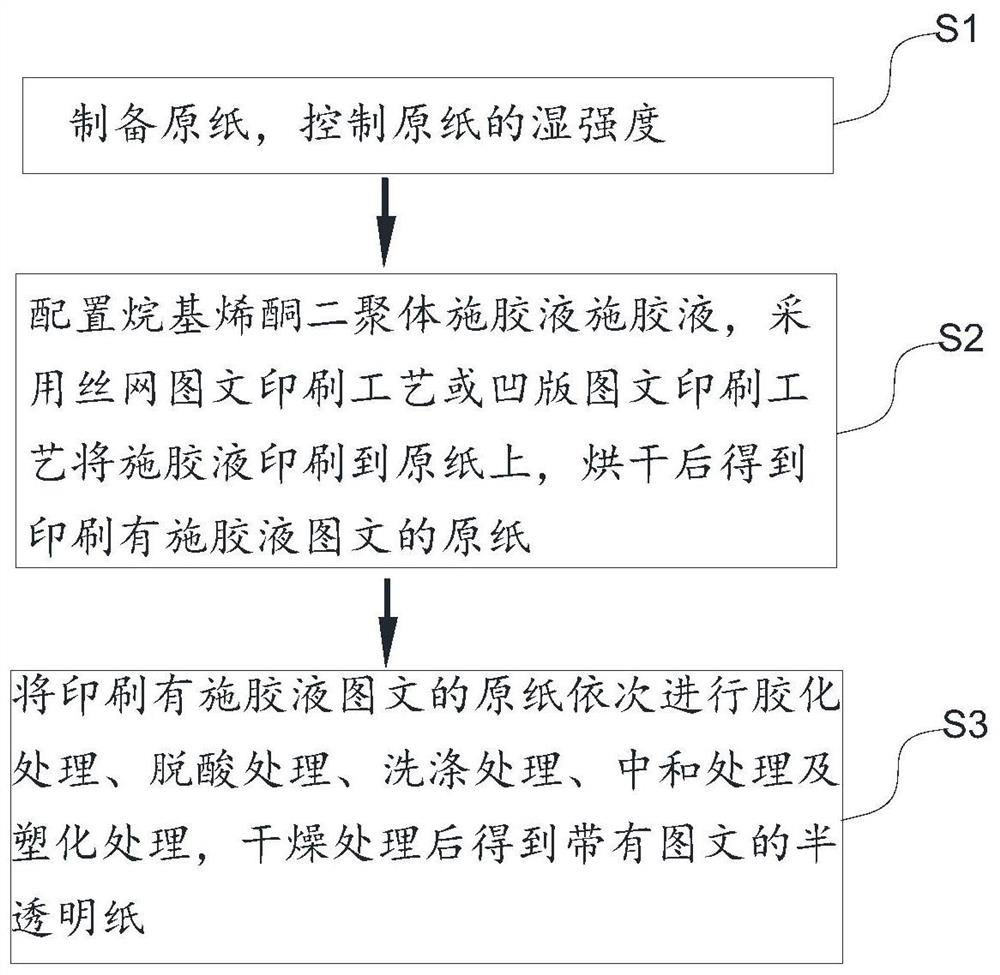

[0028] like figure 1 , The present invention provides a method of preparing a translucent paper with a graphic, comprising the steps of:

[0029] Prepare the original paper to control the wet strength of the original paper;

[0030] Configuring alkyl ketene dimer (of AKD) glue is applied, by screen or gravure printing process graphic graphic printing process glue is applied to the printing base paper, to give after drying glue applied graphic printed paper ;

[0031] The graphic printed paper glue is applied sequentially gel process, deacidification treatment, a washing treatment and a neutralization treatment plasticized, after the drying process to obtain a translucent paper with a graphic.

[0032] In particular, the concentration of alkyl ketene dimer (of AKD) 0.5 to 1.5% of the applied glue.

[0033] In particular, a method for controlling wet strength paper in papermaking is added during the preparation of the base paper wet strength agent, wet paper strength agent is 2.0-2....

Embodiment 1

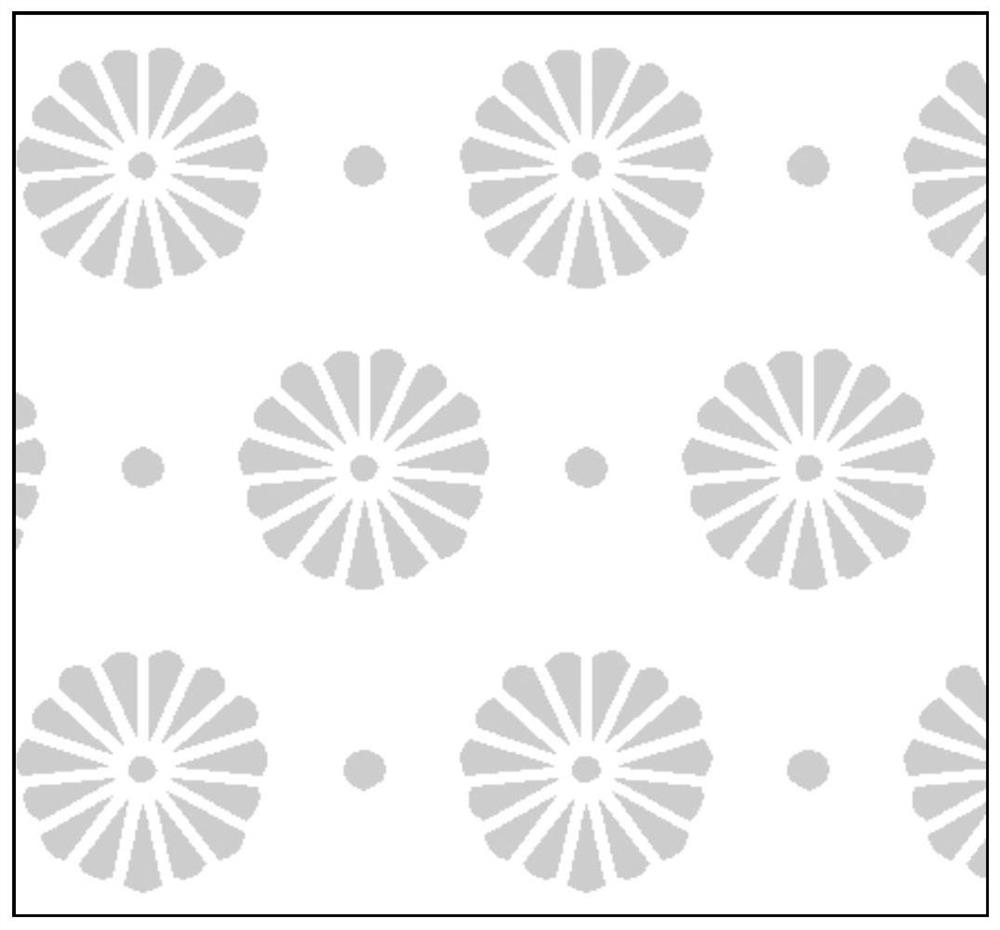

[0047] like figure 2 Shown, a sample preparation, ie preparation of graphic paper translucent (large quincunx pattern): the production of paper, Kai Lipu Canadian softwood pulp 30% (of total amount of dry pulp), hardwood pulp 70 Rizhao % (of the total amount of dry pulp), hardwood pulp and softwood pulp beaten mixing process, using free form mode beating, the beating degree 32 O The SR, wet strength agents employed Shandong Jin Lee fine chemical production of PAE wet strength agent, wet paper strength agent is the absolute dry amount of 2.0%; using 1575mm fourdrinier paper machine production, speed of 100m / min, compression pressure 1.0Mpa; paper quantitative 50 ± 1.5g / m 2 , The capillary absorbing height of 25mm / 10min, bulk of the paper 1.58cm 3 / G, breaking length 3500m, wet breaking length of 1200m, the smoothness of the front surface 45s; Printing Paper: Paper for sizing paper by screen printing cylinder having a large quincunx pattern of the mesh screen of 150 mesh, AKD...

Embodiment 2

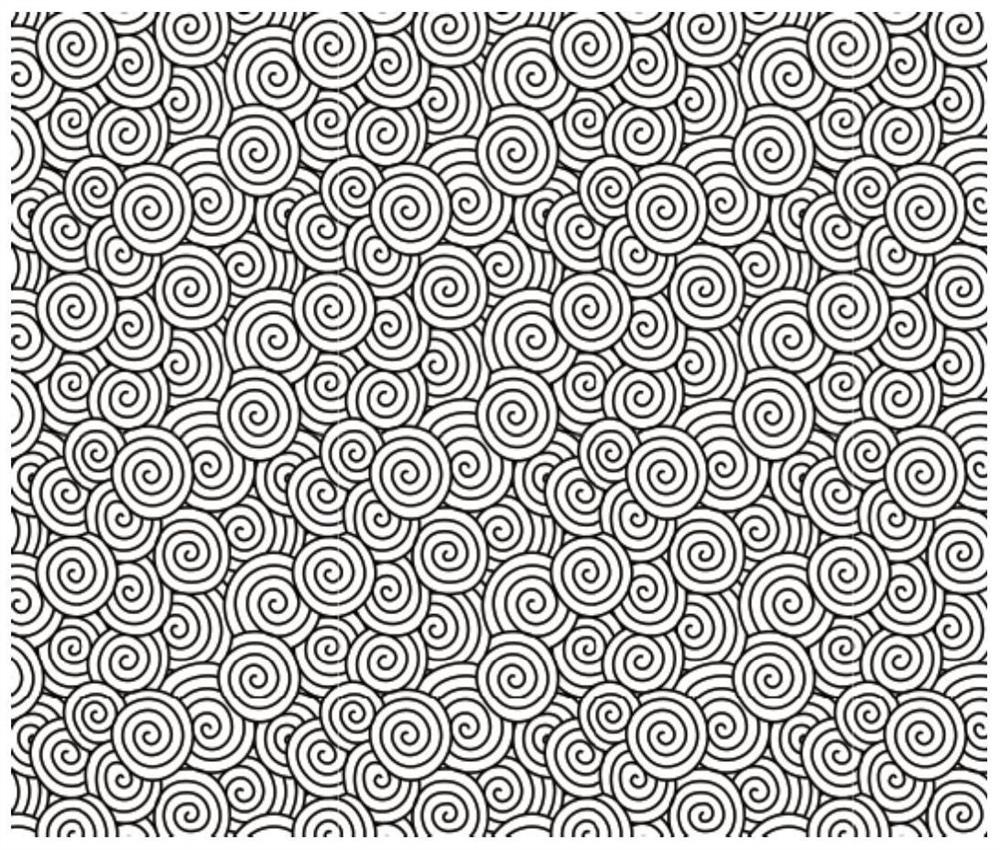

[0049] like image 3 Shown, having a translucent graphic paper manufacturing process (cloud patterns): the production of paper, Kai Lipu Canadian softwood pulp 25% (on the total amount of dry pulp), 75% hardwood pulp Rizhao (total absolute dry the amount of pulp), hardwood pulp and softwood pulp beaten mixing process, using free form mode beating, the beating degree of beating 32 O The SR, wet strength agents employed Shandong Jin Lee fine chemical production of PAE wet strength agent, wet paper strength agent is the absolute dry amount of 2.0%; using 1575mm fourdrinier paper machine production, speed of 90m / min, compression pressure 1.0Mpa; paper quantitative 70 ± 2.0g / m 2 , The capillary absorbing height of 23mm / 10min, bulk of the paper 1.62cm 3 / G, breaking length 3800m, wet breaking length 1330m, smoothness of the front surface 42s; paper printing: using a screen cylinder having a pattern of clouds, the mesh screen of 150 mesh sizing of paper, the size press solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com