Harmless and resource utilization technology combining pretreatment of electrolytic manganese residue and preparation of composite admixture for concrete from electrolytic manganese residue

An electrolytic manganese slag and pretreatment technology, applied in cement production, etc., can solve the problems of small electrolytic manganese enterprises, difficulty in achieving economical disposal scale, inability to effectively remove ammonia nitrogen and heavy metal manganese Mn in electrolytic manganese slag, and avoid secondary Effects of pollution, enhancing application value, and solving industry pain points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

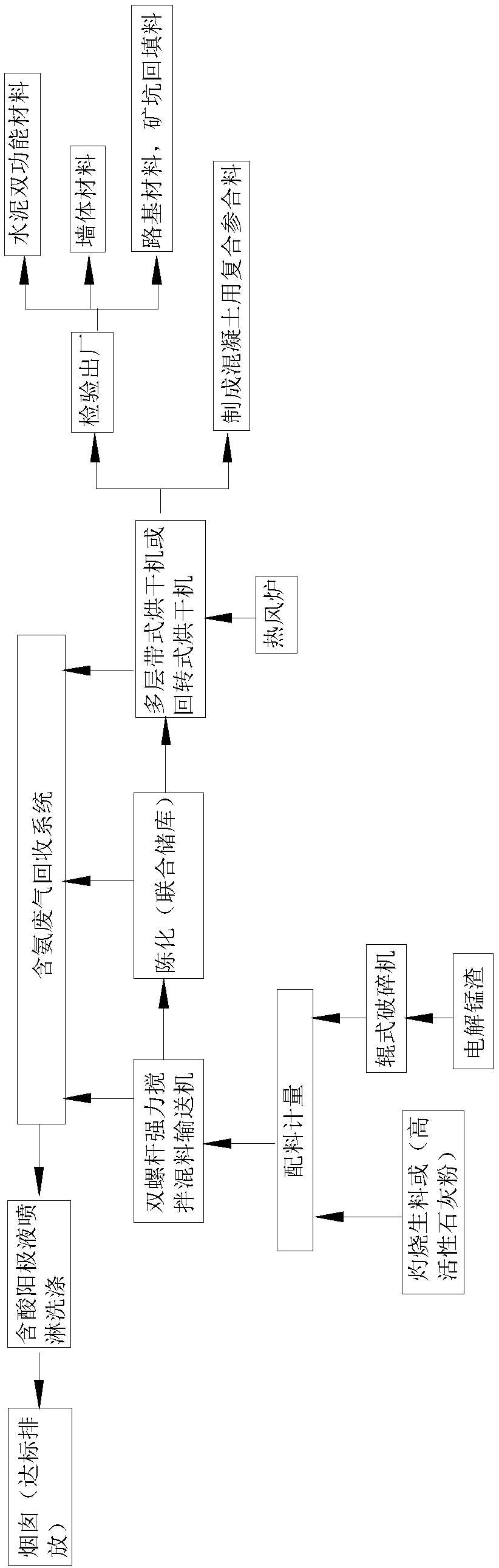

Method used

Image

Examples

Embodiment 1

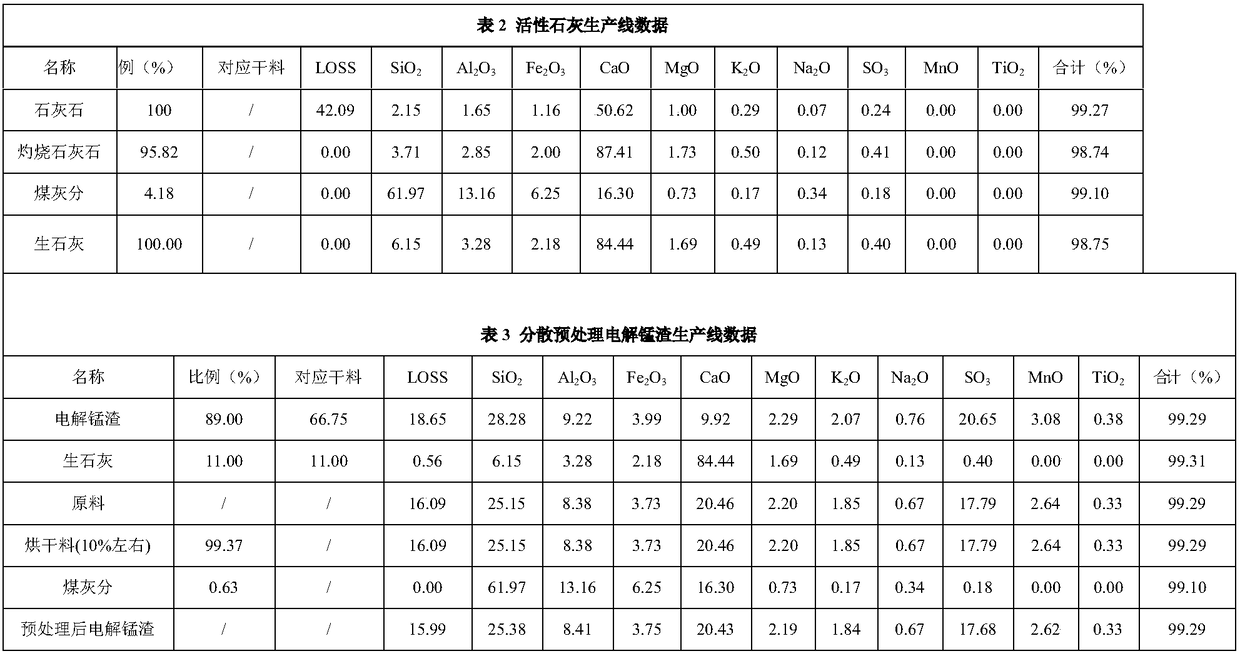

[0052] Pretreatment link: harmless treatment of electrolytic manganese slag with highly active lime. The components of highly active lime are shown in Table 1:

[0053] Table 1

[0054] name

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

Na 2 o

SO 3

highly active lime

3.71

2.85

2.00

87.41

1.73

0.50

0.12

0.41

[0055] Compound high-activity lime and electrolytic manganese slag according to the mass ratio of 1:9, and vigorously stir and mix according to step (b) in step (1), with a large amount of ammonia overflowing. After testing: the sulfuric acid in the original electrolytic manganese slag Ammonium is 3.3%. After stirring and mixing for nearly 30 minutes, the content of ammonium sulfate in the obtained mixture is 1.15%, and the ammonia gas overflow rate reaches 67%. According to the step (c) in the step (1) aging storage 2.5d, during this period, turn the material twice per hour, car...

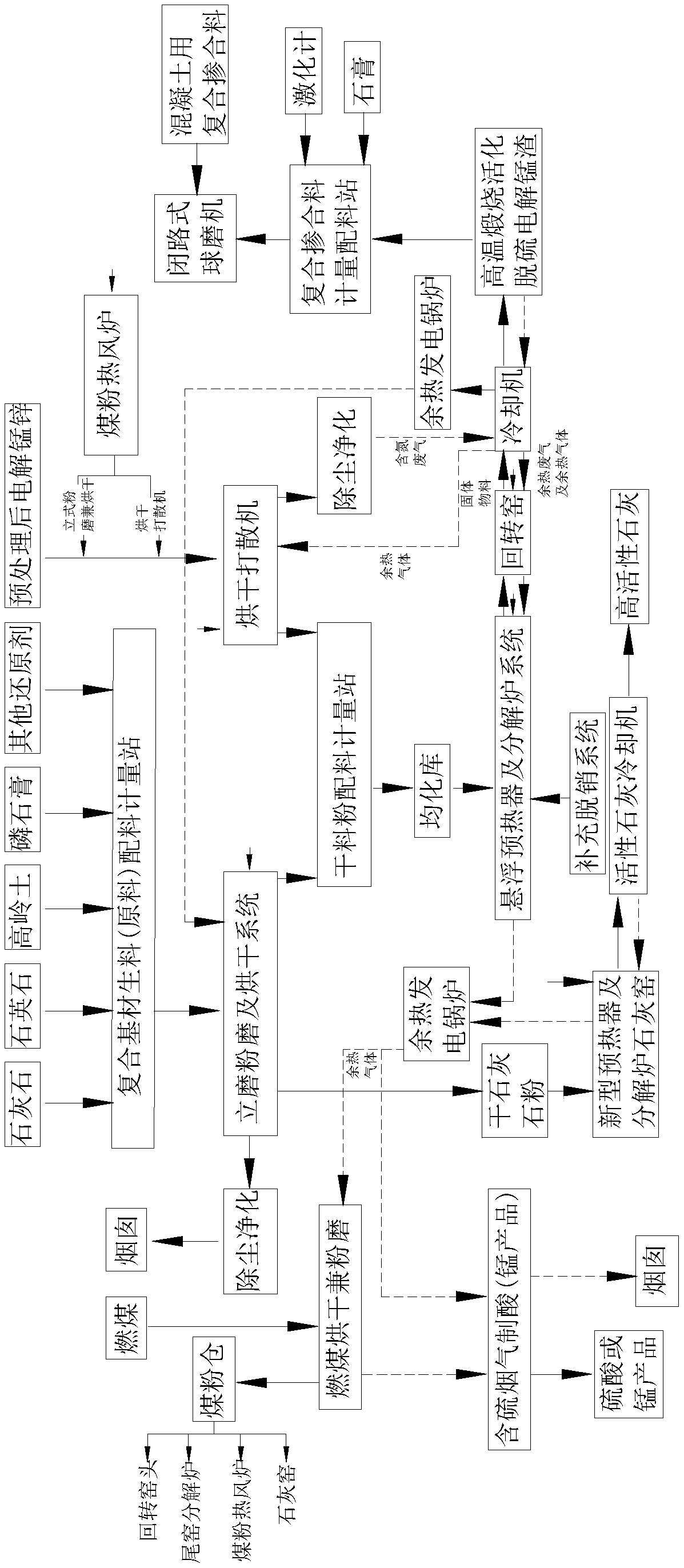

Embodiment 2

[0060] The links of making composite admixtures for concrete:

[0061]

[0062]

[0063] The data of activated desulfurization manganese slag obtained by calcination are shown in Table 5:

[0064]

[0065] The activated desulfurized manganese slag is mixed with industrial waste slag in proportion, and is ground together by a closed-circuit ball mill to form a composite admixture for concrete, which meets the technical index requirements of "JG_T 486-2015 Composite Admixture for Concrete".

[0066] In summary, the use of the electrolytic manganese slag pretreatment provided by the present invention and the harmless and resourceful utilization technology for making composite admixtures for concrete can solve the problems in the prior art that cannot effectively solve the problem of heavy metals in electrolytic manganese slag. Manganese, ammonia nitrogen pollution and other issues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com