Treatment method for manganese fixation and ammonia removal of electrolytic manganese slag

A technology of electrolytic manganese slag and treatment method, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of secondary pollution and high cost of electrolytic manganese slag, and avoid pollution and avoid secondary pollution , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

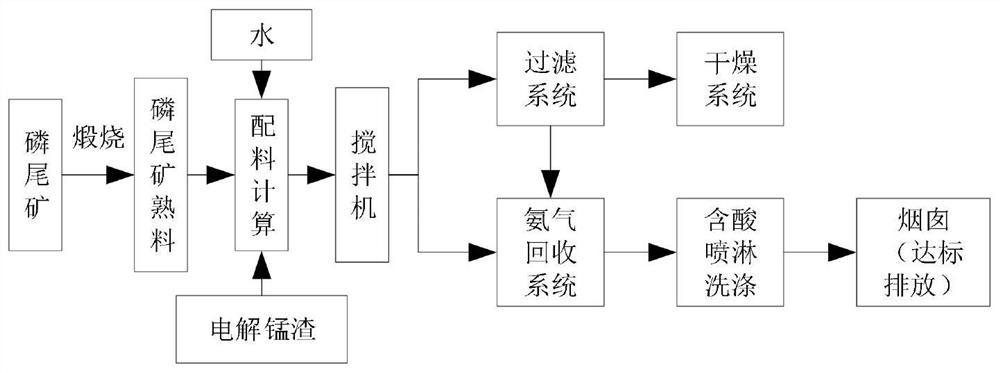

[0031] Embodiment 1: a kind of treatment method of electrolytic manganese slag solid manganese removal ammonia, this method comprises the following steps:

[0032] (1) With a sintering temperature of 900°C, a holding time of 25 minutes, and a heating rate of 5°C / min, the phosphorous tailings are calcined to obtain phosphorous tailings clinker;

[0033] (2) Add 500 kg of water and 10 kg of phosphorous tailings clinker to 80 kg of electrolytic manganese slag and adopt biaxial stirring reaction. The time of stirring reaction is 160 minutes, the temperature of stirring reaction is 20 ° C, and the gas generated during the reaction is collected. Send it into the ammonia gas recovery system to obtain the mixture;

[0034] (3) The mixture is filtered, and while filtering, the generated gas is collected and sent to the ammonia gas recovery system, then the filter residue is taken and dried at 50° C. to obtain electrolytic manganese slag for solid manganese and ammonia removal;

[0035...

Embodiment 2

[0036] Embodiment 2: a kind of treatment method of electrolytic manganese slag solid manganese removal ammonia, this method comprises the following steps:

[0037] (1) With a sintering temperature of 1000°C, a holding time of 30 minutes, and a heating rate of 10°C / min, the phosphorous tailings are calcined to obtain phosphorous tailings clinker;

[0038] (2) Add 600kg water and 12kg phosphorus tailings clinker to 100kg electrolytic manganese slag, adopt planetary stirring reaction, the time of stirring reaction is 180min, the temperature of stirring reaction is 40 ℃, and the gas that produces in the reaction process is collected and sent into the ammonia recovery system to obtain the mixture;

[0039] (3) The mixture is filtered, and while filtering, the generated gas is collected and sent to the ammonia gas recovery system, then the filter residue is taken and dried at 60° C. to obtain electrolytic manganese slag for solid manganese and ammonia removal;

[0040] In the steps (...

Embodiment 3

[0041] Embodiment 3: a kind of treatment method of electrolytic manganese slag solid manganese removal ammonia, this method comprises the following steps:

[0042] (1) With a sintering temperature of 900°C, a holding time of 35 minutes, and a heating rate of 5°C / min, the phosphorous tailings are calcined to obtain phosphorous tailings clinker;

[0043] (2) Add 700kg of water and 10kg of phosphorous tailings clinker to 80kg of electrolytic manganese slag, adopt biaxial stirring reaction, the time of stirring reaction is 160min, the temperature of stirring reaction is 50°C, and the gas generated during the reaction is collected Send it into the ammonia gas recovery system to obtain the mixture;

[0044] (3) The mixture is filtered, and while filtering, the generated gas is collected and sent to the ammonia gas recovery system, and then the filter residue is taken and dried at 70° C. to obtain electrolytic manganese slag for manganese removal and ammonia removal;

[0045] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com