Ammonia flue gas desulfurization device

A desulfurization device and flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as ammonia escape, energy consumption, and occupation of land resources, so as to improve absorption efficiency, reduce power consumption, and avoid The effect of ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

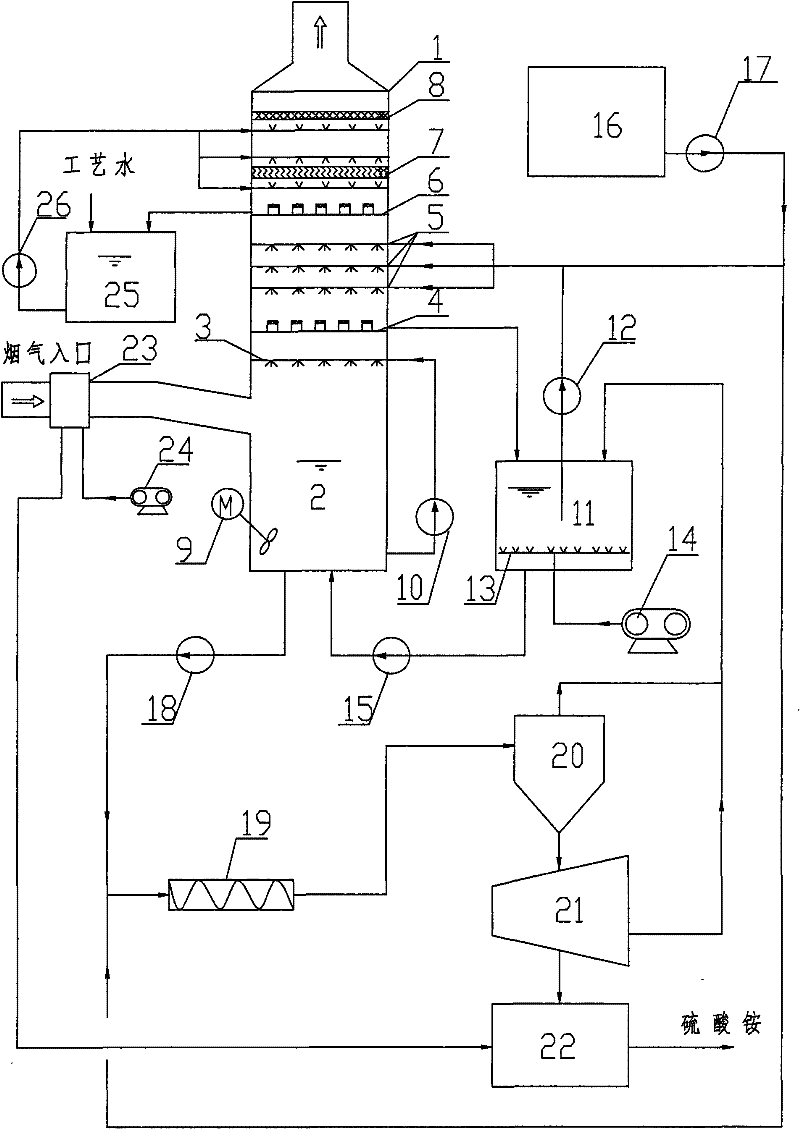

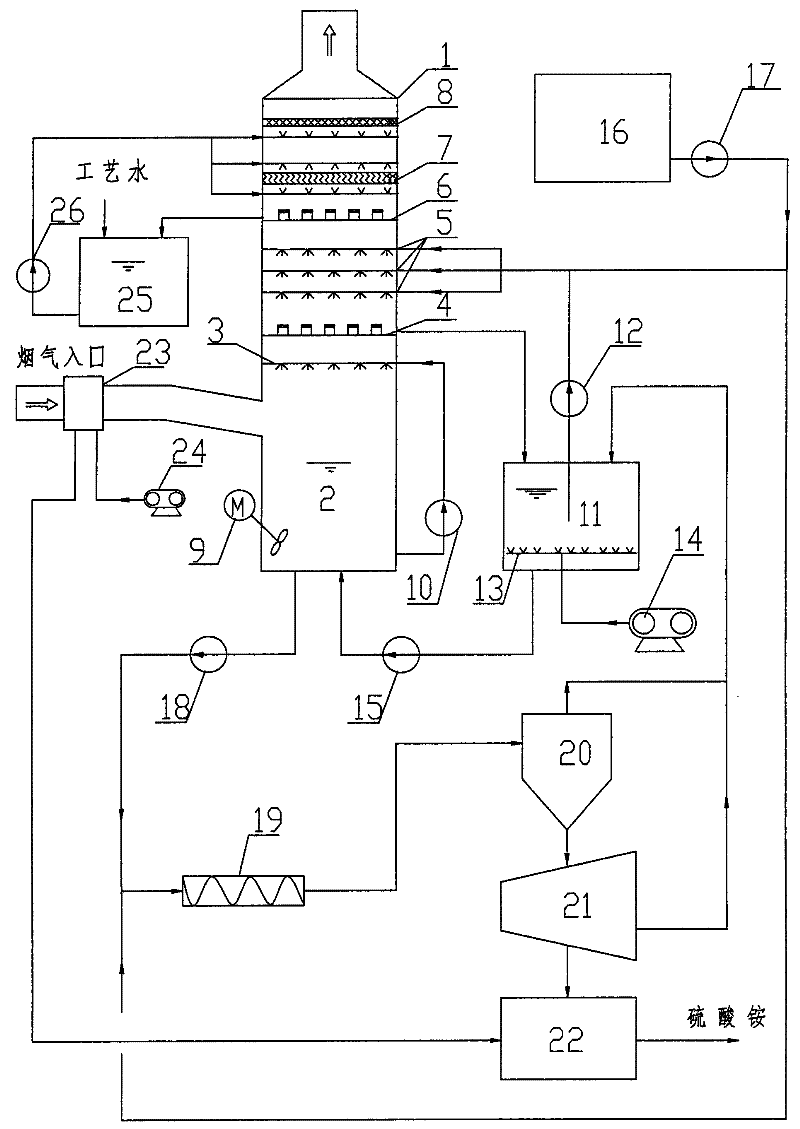

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] This process is used for flue gas desulfurization of coal-fired boilers. Such as figure 1 As shown, the high-temperature flue gas at 130-160°C enters the crystallization tank (2) at the bottom of the absorption tower (1) after passing through the heat exchanger (23), and is contacted with the cooling spray layer (3) ammonium sulfate solution for washing, and the temperature of the flue gas drops At the same time, the ammonium sulfate solution is evaporated, concentrated and crystallized, and then enters the middle part of the absorption tower (1), and the swirling absorption distribution plate (4) is combined with the absorption spray layer (5) to form the absorption section, and the SO 2 After washing and absorbing, it enters the upper part of the absorption tower (1) to install a swirl type defogging distribution plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com