Microwave solid-phase method for synthesizing tetraphenylporphyrinatozinc (II)

A technology of tetrabenzoporphyrin and solid-phase synthesis, applied in the direction of organic chemistry, etc., can solve the problems of difficult separation and purification, many operation steps, long reaction time, etc., and achieves the effect of reducing cost, reducing reaction energy barrier and facilitating purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Microwave Synthesis of Tetrabenzoporphyrin Zn(Ⅱ)

[0026] Weigh 0.19g (18mmol) malonic acid, 0.33g (18mmol) potassium phthalimide and 0.75g (3.75mmol) zinc acetate in a mortar, mix and grind for 5min, transfer the mixed powder to a 150mL round bottom flask , the microwave power was 800W under the radiation for 5 minutes after the reaction was completed, the product was taken out, and the crude product was obtained by cooling in the dark. The crude product was separated by column chromatography to obtain the refined product. The yield was 30%.

[0027] Adopt this method to carry out synthesis, because of fast reaction speed, short reaction time, no sublimation phenomenon. The conventional method is to fully grind the raw materials, mix them uniformly, first place the powder on a quartz boat, and then put it into a quartz tube, and react at 400° C. for 60 minutes under the protection of argon, with a yield of 15%. It can be seen from the comparison that this method can...

Embodiment 2

[0029] Product map verification

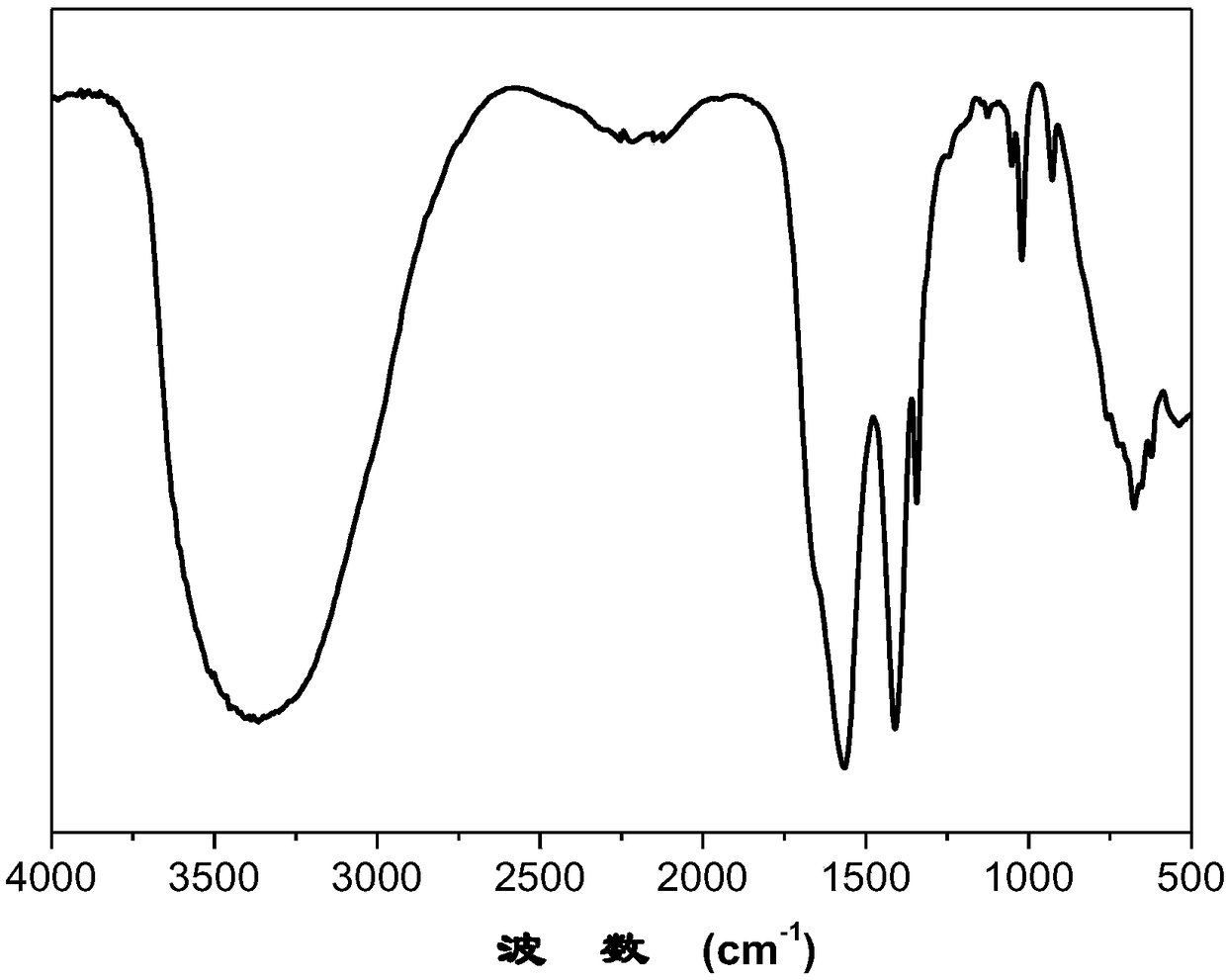

[0030] Infrared Spectrum Verification: figure 1 The infrared spectrogram of the tetrabenzoporphyrin zinc (II) prepared in embodiment 1 is shown, as can be known from the analysis in the figure, 1400cm -1 ~1600cm -1 The strong absorption peaks can be attributed to the characteristic absorption peaks of C=C and C=N in the porphyrin molecule, 1340cm -1 is the C-N stretching vibration absorption peak.

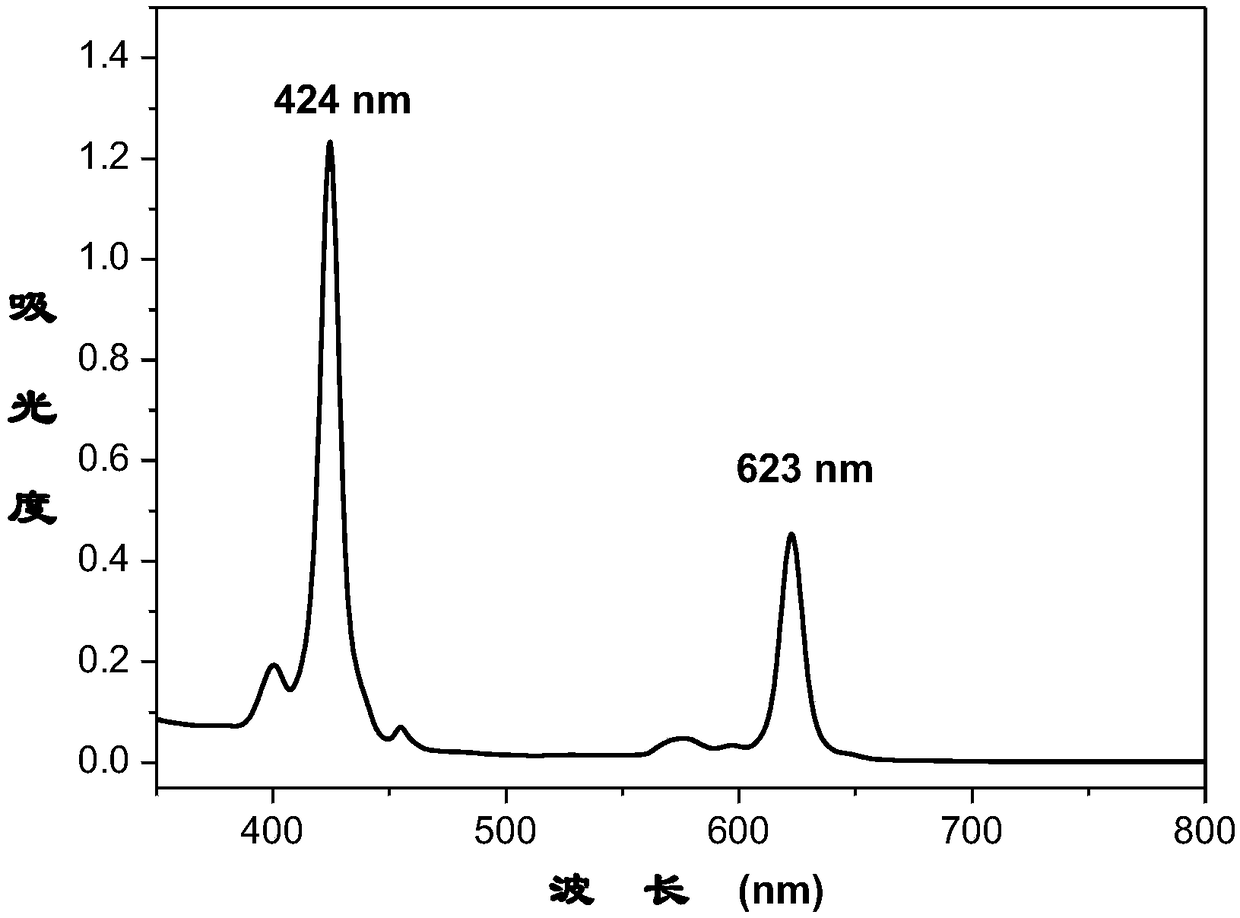

[0031] UV Spectrum Verification: figure 2 The ultraviolet spectrogram of the tetrabenzoporphyrin zinc (II) prepared in Example 1 is shown, as can be seen from the analysis in the figure, there are two strong absorptions at 424nm and 623nm, wherein the strong absorption peak at 424nm is The characteristic peak of porphyrin Soret band, the absorption peak at 623nm is the Q band absorption peak.

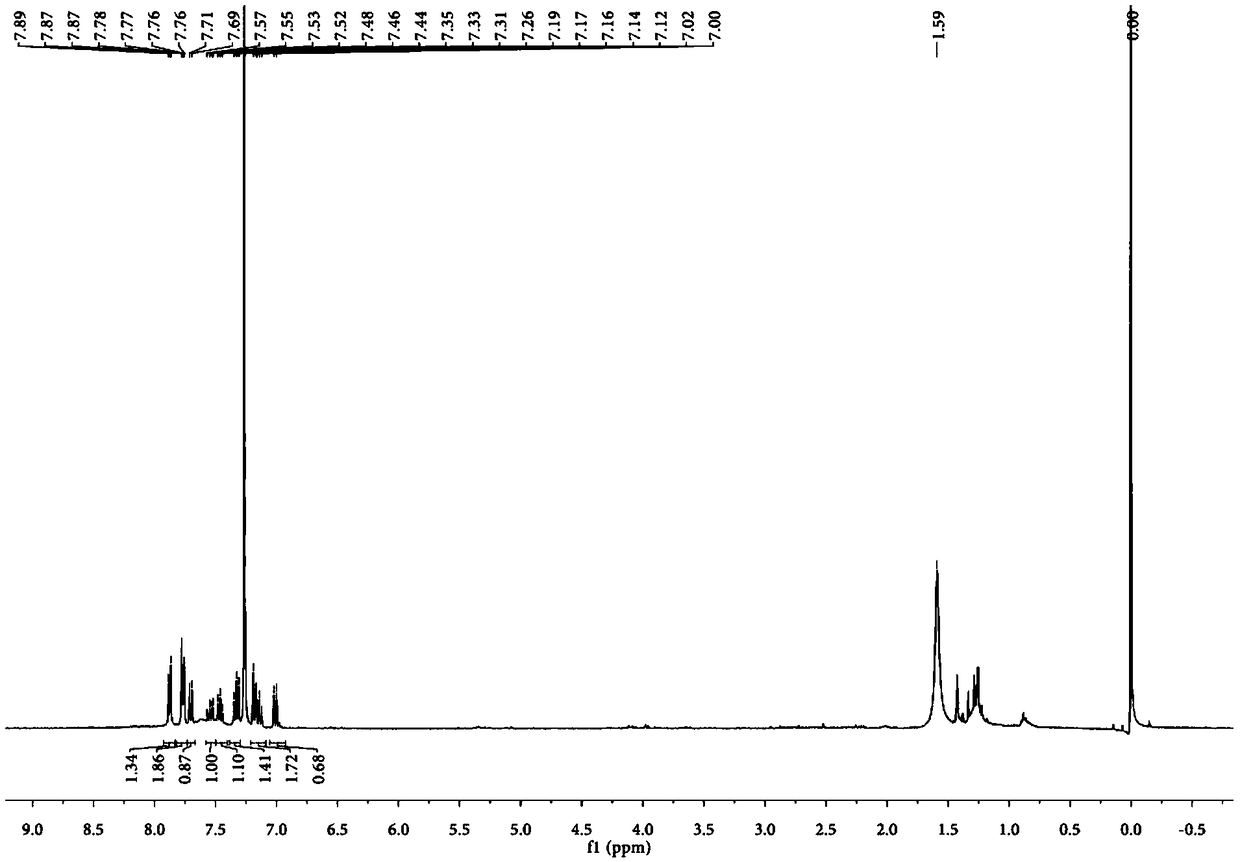

[0032] NMR verification: 1 H NMR: 7.89(m,2H), 7.78(m,4H), 7.71(d,2H), 7.57(m,4H), 7.35(m,3H), 7.19(m,4H), 7.02(d,1H ).

[0033] From the above spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com