Antibacterial antistatic PS composite material and preparation method thereof

A composite material and antistatic technology, which is applied in the field of antibacterial and antistatic PS composite materials and its preparation, can solve the problems of unsatisfactory antistatic and antibacterial performance, and achieve the effect of improving antistatic performance and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

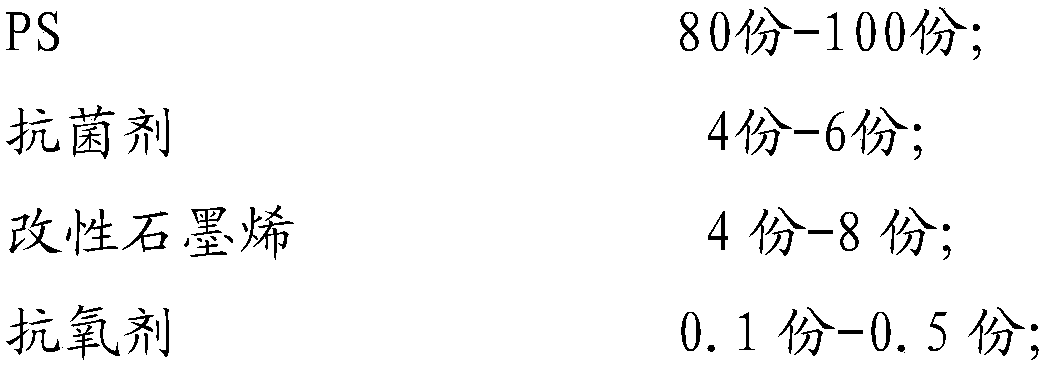

Method used

Image

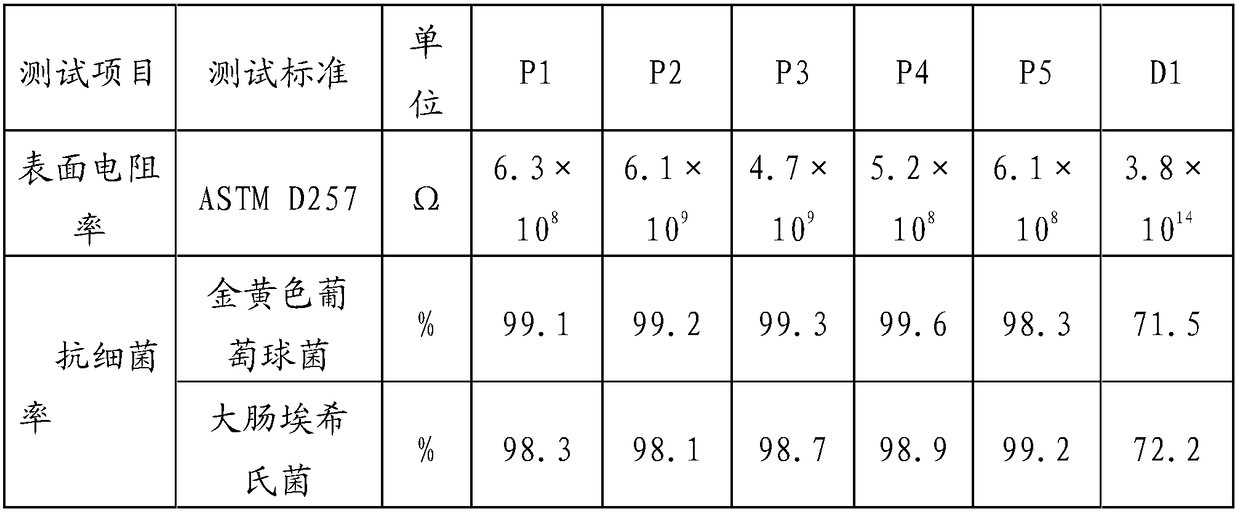

Examples

preparation example Construction

[0036] The preparation method of described antibacterial agent, comprises the following steps:

[0037] (1) Weigh a certain amount of hexapraseodymium undecoxide, deionized water, nitric acid, and hydrogen peroxide, add them to the reaction vessel, and react at 30-50°C for 6-8h to form Pr(NO3) 3 ·6H 2 O; the mass ratio of hexapraseodymium undecyl oxide, deionized water, nitric acid, and hydrogen peroxide is (30-40): (200-240): (60-80): (50-70).

[0038] (2) Take a certain amount of sodium o-hydroxyphenylacetate, ethanol, deionized water, 5-chloro-7-hydroxyquinoline, Pr(NO3) 3 ·6H 2 O, react at 60-80°C for 8-12h to obtain solution A; sodium o-hydroxyphenylacetate, ethanol, deionized water, 5-chloro-7-hydroxyquinoline, Pr(NO3) 3 ·6H 2 The mass ratio of O is (20-30):(120-160):(180-220):(30-40):(60-80).

[0039] (3) Adjust the pH value of solution A to neutral with nitric acid or sodium hydroxide, wash, filter with suction, dry, grind, and pass through a 500-mesh sieve to obt...

Embodiment 1

[0049] (1) Take 80 parts of PS, 4 parts of antibacterial agents, 4 parts of modified graphene, 0.1 part of Irganox168 and mix and stir evenly to obtain a mixture;

[0050] (2) Extruding and granulating the mixture obtained in the step (1) to obtain PS composite material P1.

[0051] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 160°C, the temperature of the second zone is 210°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 210°C, the temperature of the sixth zone is 210°C, The head temperature is 210°C, and the screw speed is 200r / min.

Embodiment 2

[0053] (1) Weigh 100 parts of PS, 6 parts of antibacterial agent, 8 parts of modified graphene, 0.1 part of Irganox168, 0.2 part of Irganox1010, 0.2 part of Irganox1330 and mix and stir evenly to obtain a mixture;

[0054] (2) Extruding and granulating the mixture obtained in step (1) to obtain PS composite material P2.

[0055] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 180°C, the temperature of the second zone is 250°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, and the temperature of the sixth zone is 250°C. The head temperature is 250°C, and the screw speed is 280r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com