Gear with texturing coating

A textured and gear technology, applied in belts/chains/gears, components with teeth, gear lubrication/cooling, etc. The effect of surface temperature, increasing specific surface area and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

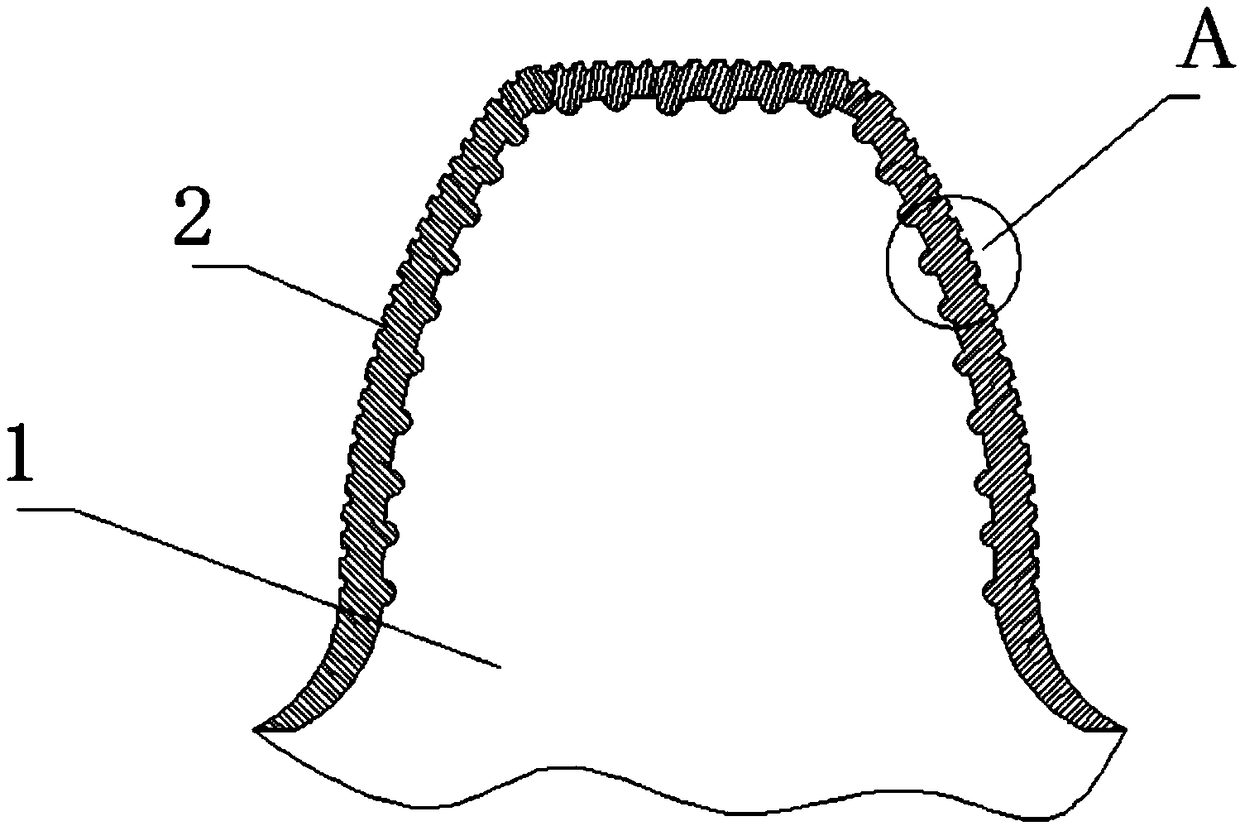

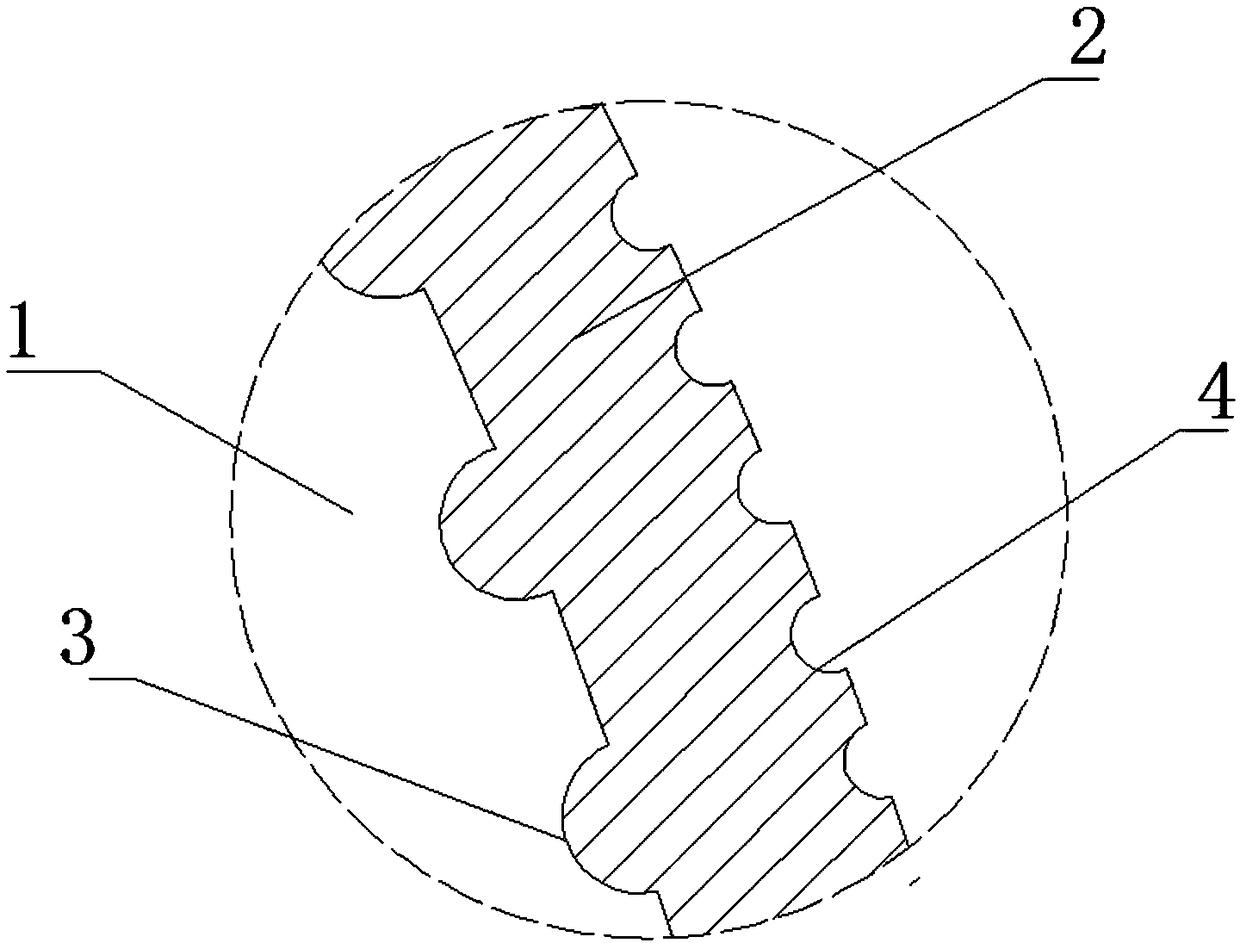

[0044] Embodiment 1, with reference to figure 1 , 2 As shown, the present invention provides a gear with a textured coating 2 , including a gear body 1 and a coating 2 attached to the gear body 1 . The coating 2 has good wear resistance and heat insulation performance, which is beneficial to reduce friction and increase the thermal deformation of the gear body 1 .

[0045] The surface of the gear body 1 is evenly distributed with a plurality of first micropits 3, through the texturing of the surface of the gear body 1, the microstructure of the surface of the gear body 1 can be changed, and the specific surface area of the tooth surface of the base can be effectively increased, forming a coating 2 The coating provides a good adhesion surface and increases the adhesion between the coating 2 and the tooth surface of the substrate, thereby improving the anti-stripping and breakage of the coating 2. A plurality of textured regions are distributed on the surface of the coating ...

Embodiment 2

[0078] The gear with textured coating 2 provided by the embodiment of the present invention has the same realization principle and technical effect as that of embodiment 1. For a brief description, reference can be made to embodiment 1 for the parts not mentioned in this embodiment. Corresponding content.

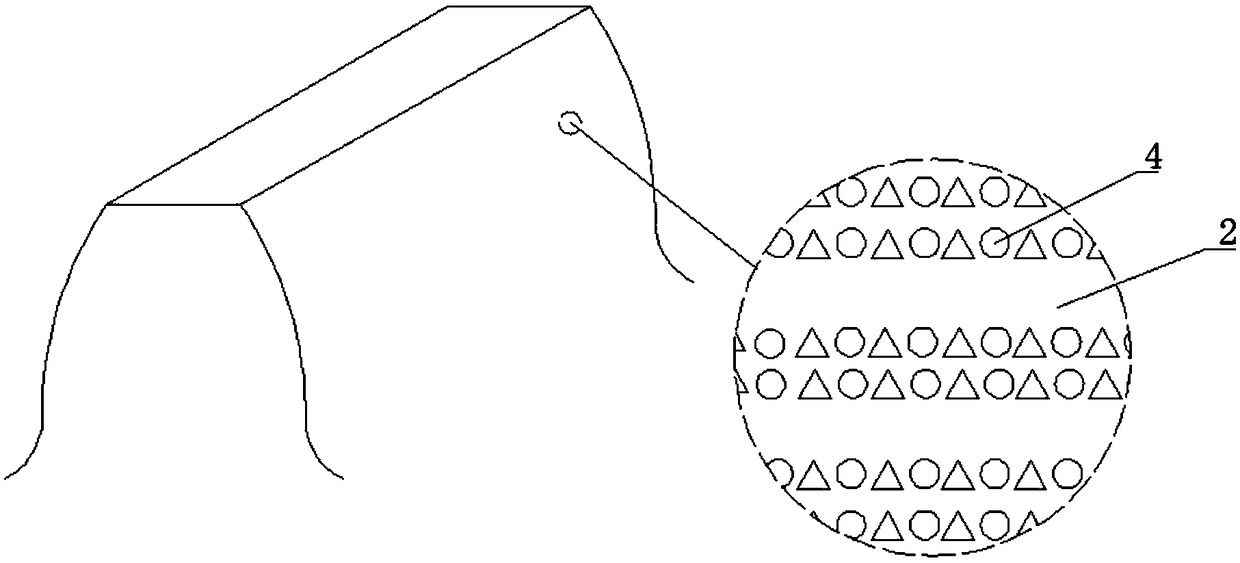

[0079] refer to Figure 4 As shown, the textured region is a mixed micro-texture, the mixed micro-texture is selected from spherical cap and square texture, along the axial direction of the gear, a plurality of the second micro-pits 4 The textures of the second dimples 4 are the same, and the textures of two adjacent second micropits 4 are different along the circumferential direction. Optionally, other types of arrangement, such as the same texture along the axial direction of the gear, different textures along the circumferential direction of the gear, etc., can also be applied to the textured area.

Embodiment 3

[0081]The gear with textured coating 2 provided by the embodiment of the present invention has the same realization principle and technical effect as that of embodiment 1. For a brief description, the details not mentioned in this embodiment can be referred to in embodiment 1. Corresponding content.

[0082] refer to Figure 5 As shown, the textured region is a mixed micro-texture, the mixed micro-texture is selected from square and triangular textures, along the axial direction of the gear, the texture of a plurality of the second micropits 4 The textures of the two adjacent second micropits 4 are different along the circumferential direction. Optionally, other types of arrangement, such as the same texture along the axial direction of the gear, different textures along the circumferential direction of the gear, etc., can also be applied to the textured area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com