Photo-thermal integrated control burner

A comprehensive control and burner technology, applied in the direction of control of combustion, burner, combustion method, etc., can solve problems such as inability to stay away, environmental pollution, and inability to ensure sufficient combustion, etc., to achieve the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

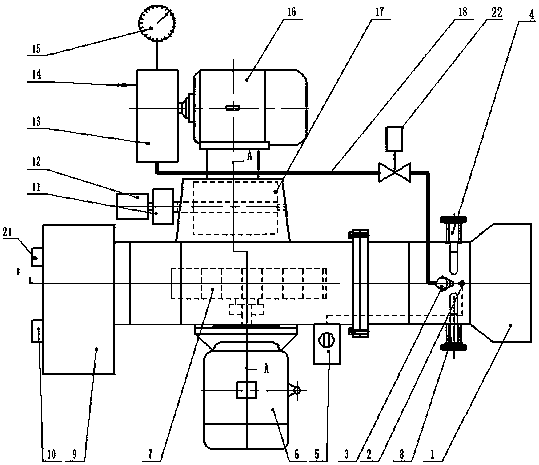

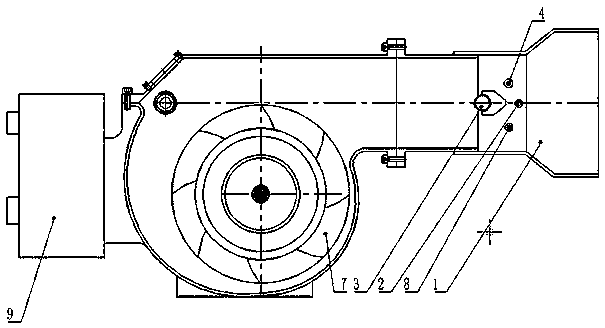

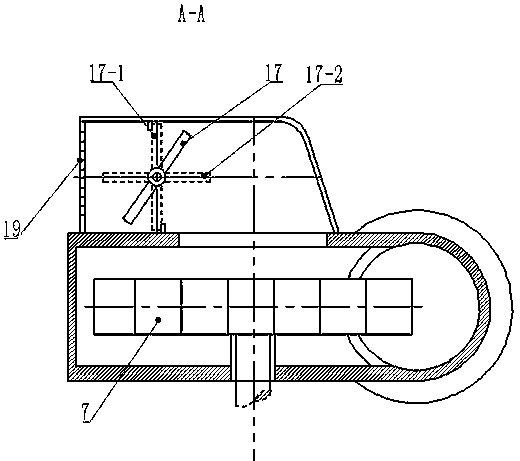

[0013] Such as figure 1 As shown, the photothermal integrated control burner of the present invention includes a fuel supply device composed of a high-pressure pump 13, an oil inlet pipeline 14, a pressure gauge 15, an oil supply motor 16, and an electric regulating valve 22; Air supply system consisting of reducer 11, damper shutter adjustment servo motor 12, impeller 7, and impeller motor 6; control device consisting of control box 9, light intensity control instrument 10, and temperature control instrument 21; light intensity sensing device 8; ignition Combustion system composed of device 5, temperature sensor 4, fuel injector 3, ignition needle 2, diffusion cover 1, etc. When the system starts, first set the highest temperature value in the temperature setting instrument 21, start the impeller motor 6, the ignition device 5 and the oil supply motor 16 in sequence, and at this time, the fuel oil is delivered to the high-pressure oil pump 13 by the oil inlet pipe 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com