Online white light interference thickness gauge

A technology of white light interferometry and thickness gauge, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve problems such as powerlessness, poor measurement robustness, and influence of induction coil distance, and achieve enhanced robustness and resolution Substantial, impact-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

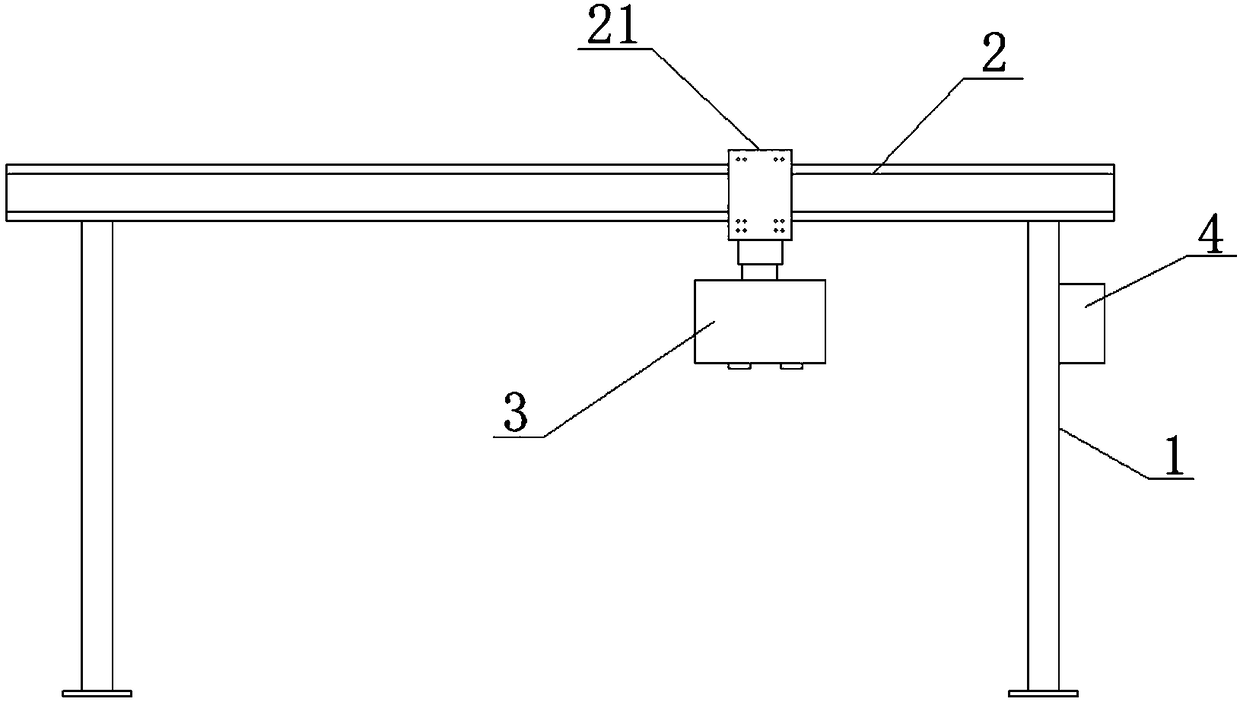

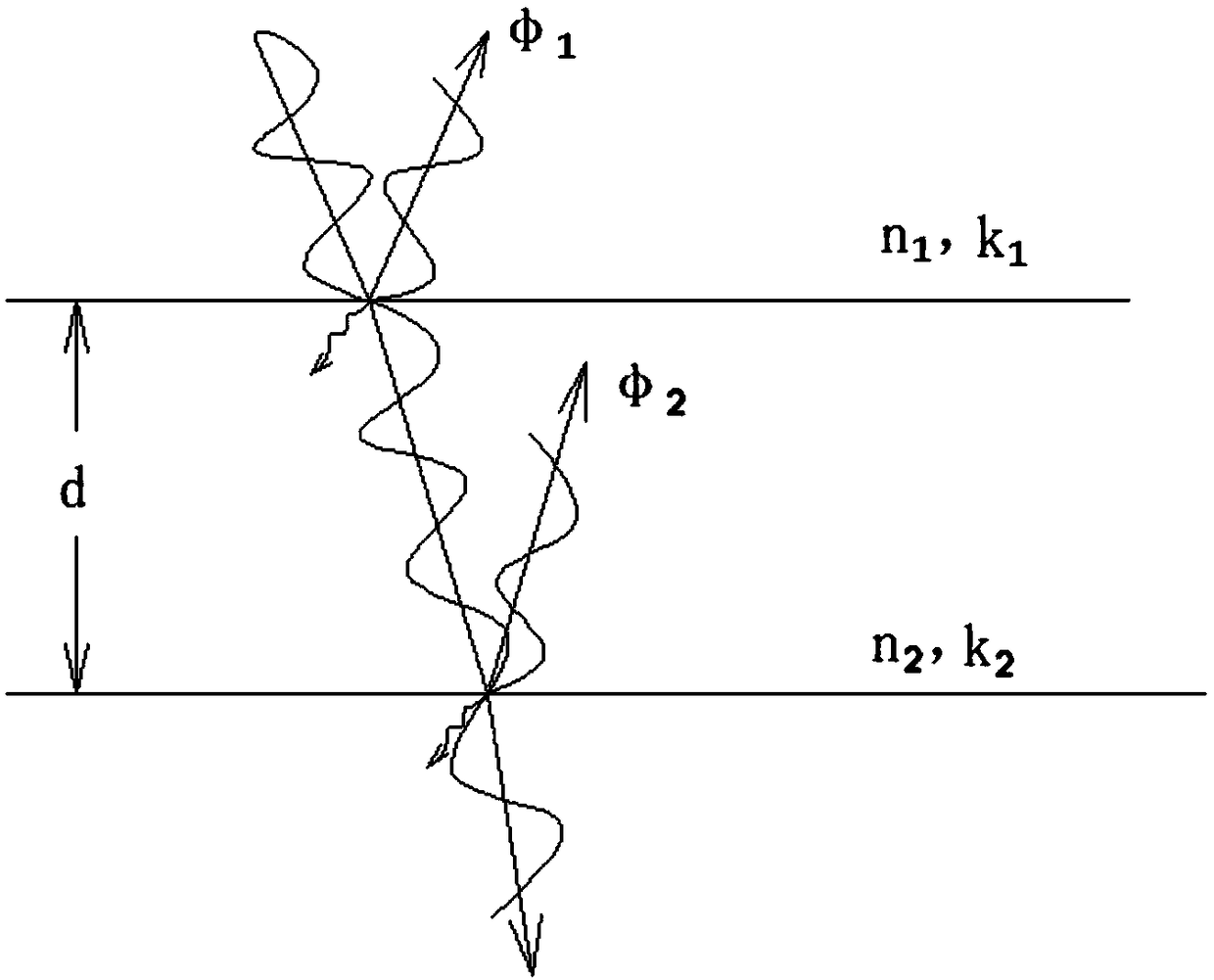

[0025] Such as Figure 1-2 As shown, the present invention discloses an online white light interferometric thickness gauge, including a frame 1, a servo drive system 2, a probe system 3 and an electric control system 4. The servo drive system 2 is installed laterally on the upper part of the frame 1, and the The servo drive system 2 is provided with a probe base 21, and the probe system 3 is installed below the probe base 21. The probe system 3 includes a light source system, a spectrometer, a light leakage type light collector and a cooling system. The light source system adopts Wide-spectrum halogen light source or white LED light source, the cooling system is cooled by air cooling or air cooling, and the light leakage collector can collect the reflected light when the measured film is uneven or the film is vibrating into the spectrometer. The frame 1 is made of super duralumin profile. The servo drive system 2 includes a preloading guide rail, a preloading screw and a ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com