A yarn-shaped humidity sensor

A humidity sensor and yarn technology, applied in the field of flexible sensors, can solve problems such as insufficient bonding force, inability to weave into fabrics, etc., and achieve the effects of widening the test range, simple preparation method, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

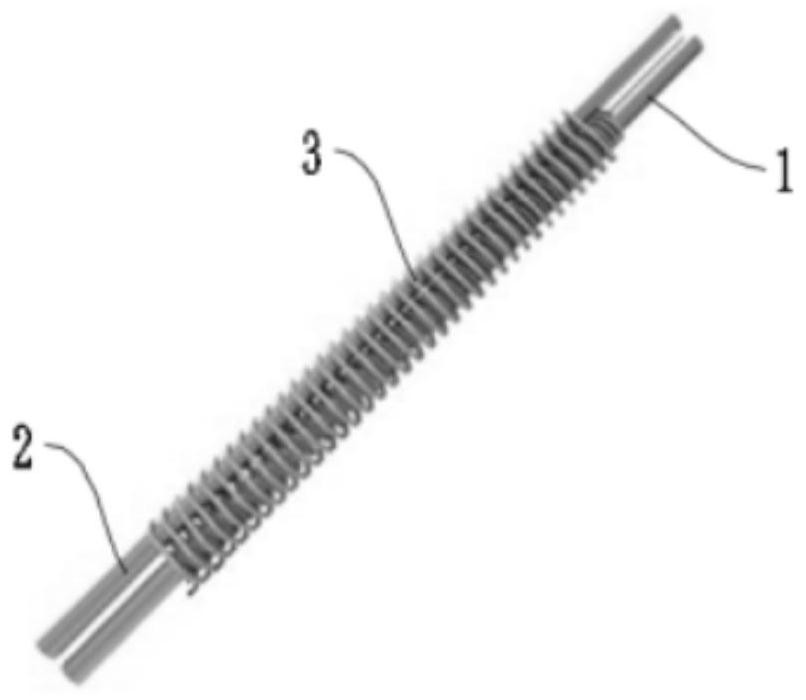

[0064] The preparation steps of a biaxial wrapping humidity sensor provided in this embodiment are as follows:

[0065] (1) Metal copper wire is selected as the first electrode 1 and the second electrode 2, and the special-shaped section functionalized yarn is selected as the sensitive material. First, the first electrode 1, the second electrode 2 and the special-shaped section functionalized yarn are placed in an anhydrous Soak in ethanol for 0.5h, then wash 5 times with deionized water, and dry at 60°C for 1h to ensure that the material is free of other impurities.

[0066] (2) Winding the special-shaped cross-section functionalized yarn on the first electrode 1 in an "S" or "Z" shape to obtain a preform.

[0067] (3) Place the prefabricated body and the second electrode 2 in parallel, and then take another special-shaped cross-section functionalized yarn and wind it on the first electrode and the second electrode in an "S" or "Z" shape to form a double electrode. The shaft...

Embodiment 2

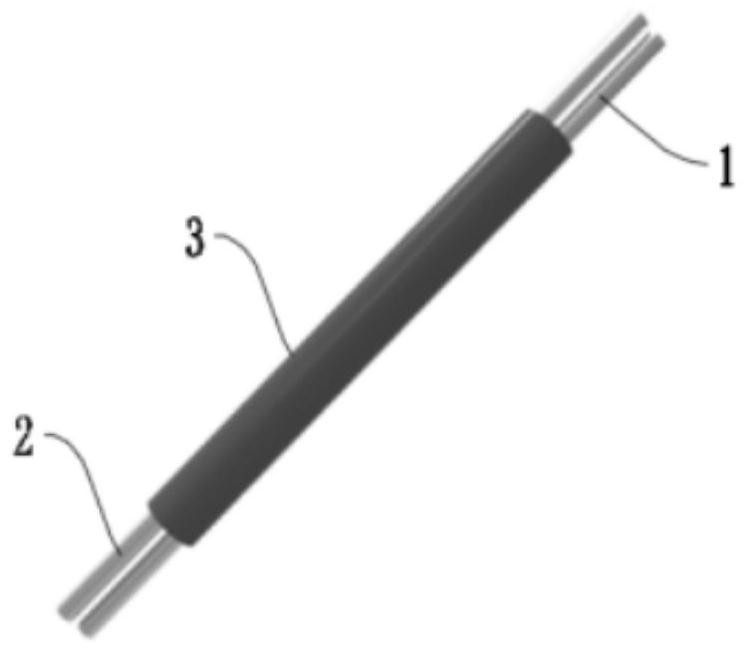

[0069] The preparation steps of a biaxial dip-coated humidity sensor provided in this embodiment are as follows:

[0070] (1) Select metal copper wire as the first electrode 1 and the second electrode 2, first soak the first electrode 1 and the second electrode 2 in absolute ethanol for 0.5h, and then use deionized water to wash 5 times to ensure that the materials For other impurities, dry at 60°C for 1 hour.

[0071] (2) Configure sensitive material 3: polyimide needs to be dissolved in N-methylpyrrolidone first to form a polyimide solution with a mass fraction of 15%.

[0072](3) Coating a polyimide solution with a mass fraction of 15% as the sensitive material 3 on the first electrode 1, repeating the coating step three times and then drying at 180° C. for 2 hours to obtain a preform.

[0073] (4) Place the preform and the second electrode 2 in parallel, then coat the polyimide solution on the surface of the preform and the second electrode 2, repeat the coating step 5 ti...

Embodiment 3

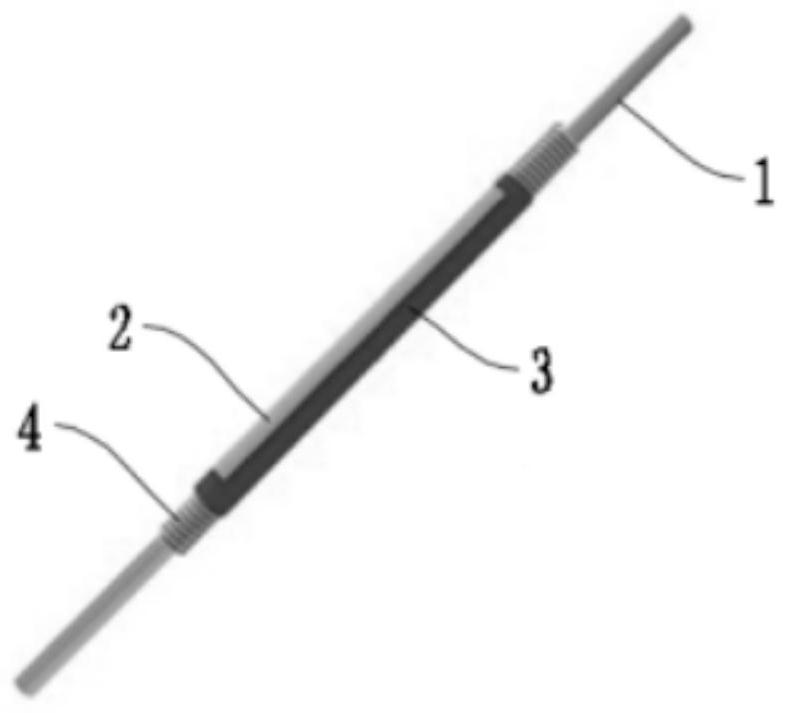

[0075] The preparation steps of a uniaxial coated humidity sensor provided in this embodiment are as follows:

[0076] (1) Select metal copper wire as the first electrode 1, silk as the base yarn 4, first soak the first electrode 1 and the base yarn 4 in absolute ethanol for 0.5h, and then use deionized water to wash 5 times to ensure The material has no other impurities, and is dried at 60°C for 1 hour.

[0077] (2) Configure sensitive material 3: polyimide needs to be dissolved in N-methylpyrrolidone first to form a polyimide solution with a mass fraction of 15%.

[0078] (3) Wrap the base yarn 4 on the first electrode 1 in an "S" or "Z" shape, then coat the polyimide solution on the first electrode 1, repeat the coating step 5 times, Dry at 180°C for 2 hours and vacuum dry at 100°C for 12 hours to obtain a preform.

[0079] (4) Partially cover the prefabricated body by the mask plate method, and then sputter metal silver ions onto the surface of the sensitive material 3 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com