A lithographic method, a mask, and a lithographic system

A mask and lithography technology, applied in the fields of masks, lithography systems, and lithography methods, can solve problems such as large overlay errors, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

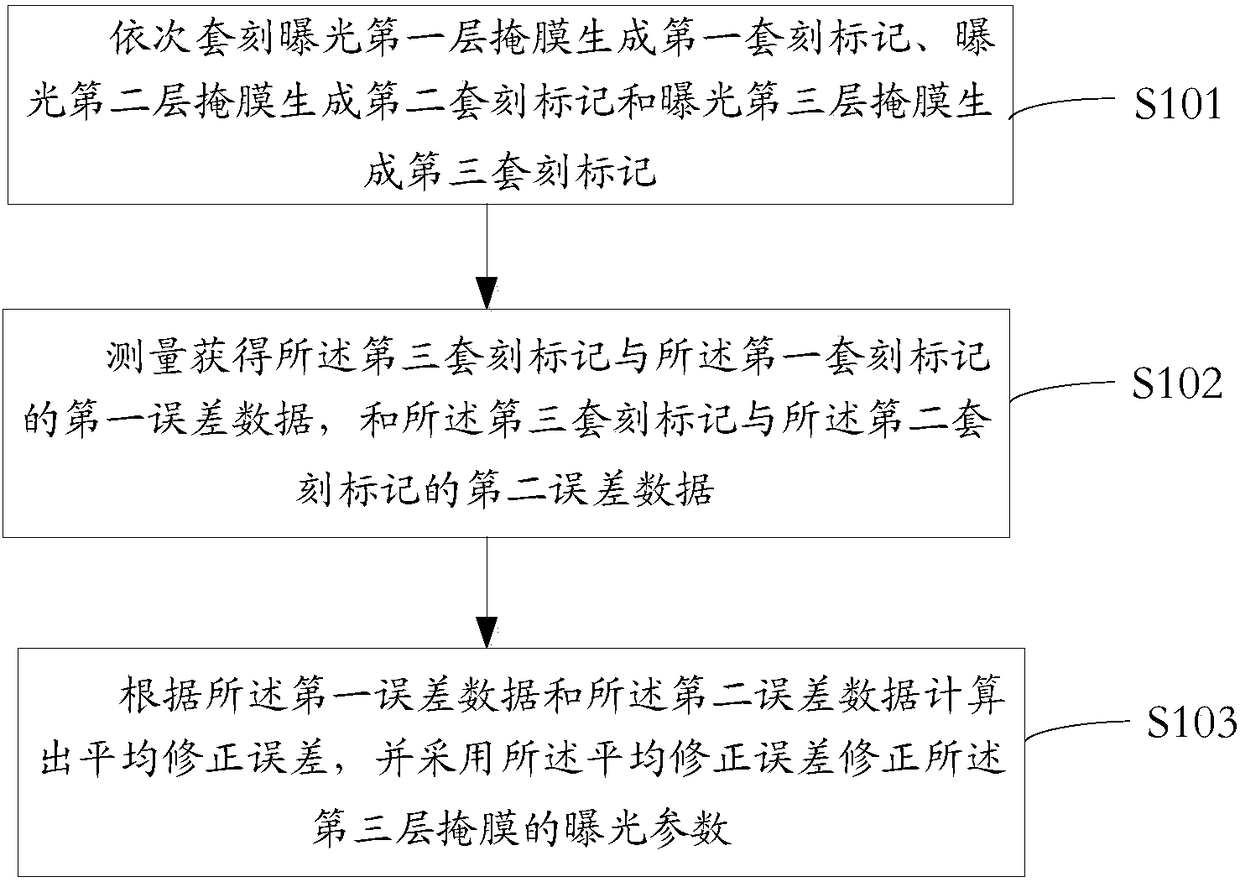

[0037] In this embodiment, a photolithography method is provided, such as figure 1 shown, including:

[0038] Step S101, sequentially overetching and exposing the first layer of mask to generate the first overlay mark, exposing the second layer of mask to generate the second overlay mark, and exposing the third layer of mask to generate the third overlay mark;

[0039] Step S102, measuring and obtaining the first error data of the third overlay mark and the first overlay mark, and the second error data of the third overlay mark and the second overlay mark;

[0040] Step S103: Calculate an average correction error according to the first error data and the second error data, and use the average correction error to correct the exposure parameters of the third-layer mask.

[0041] It should be noted that overlay is a lithography process in which the patterns exposed by multiple layers of masks are stacked together. The lithography machine uses the first layer of mask until all th...

Embodiment 2

[0057] This embodiment provides a multi-layer mask, including:

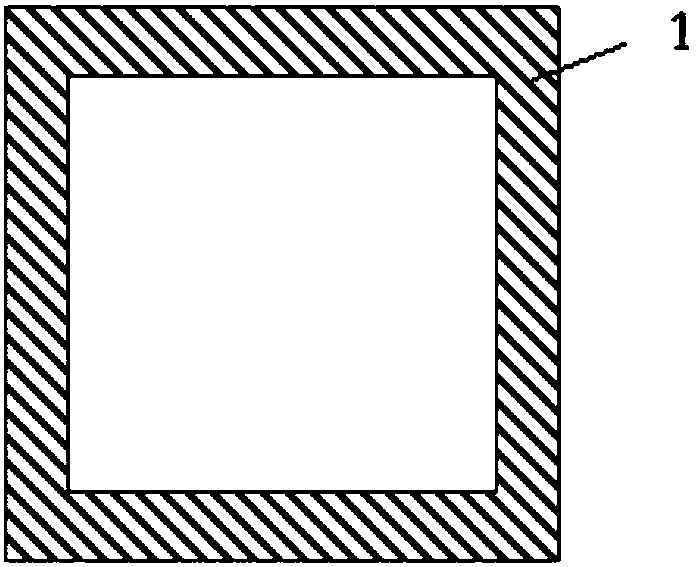

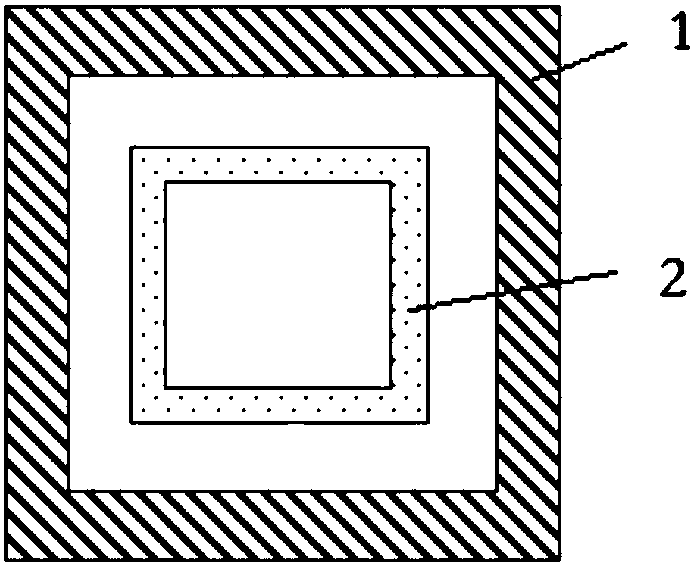

[0058] The first overlay mark pattern on the first layer mask, the second overlay mark pattern on the second layer mask, and the third overlay mark pattern on the third layer mask, wherein the A layer of masks, a second layer of masks and a third layer of masks are masks used for sequential overetching and exposure; the first set of engraving mark patterns, the second set of engraving mark patterns and the third set of engraving marks The sizes of the engraved marks are all different, so that the first, second and third overlay marks generated by the corresponding overlay exposure are in a ring-shaped triple nested shape.

[0059] In the embodiment of the present application, the first set of engraving marks is a rectangular mark or a hollow rectangular mark; the second set of engraving marks is a rectangular mark or a hollow rectangular mark; the third set of engraving marks is a rectangular mark or a hollow re...

Embodiment 3

[0063] This embodiment provides a lithography system, such as Image 6 shown, including:

[0064] The lithography machine 601 is used for sequentially overetching and exposing a first layer of mask to generate a first overlay mark, exposing a second layer of mask to generate a second overlay mark, and exposing a third layer of mask to generate a third overlay mark;

[0065] The measuring machine 602 is used to measure and obtain the first error data of the third overlay mark and the first overlay mark, and the second overlay of the third overlay mark and the second overlay mark. Error data; calculate the average correction error according to the first error data and the second error data, and transmit the average correction error to the lithography machine, so that the lithography machine adopts the average correction error Error correcting exposure parameters of the third layer mask.

[0066] In the embodiment of the present application, the measuring machine 602 is further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com