A Mixed Model Based Concentration Prediction Method for Thickener Underflow

A concentration prediction and mixed model technology, applied in prediction, biological neural network model, data processing application, etc., can solve the problems of increasing the cost of mineral processing, cumbersome modeling process, and restricting the production efficiency of thickeners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

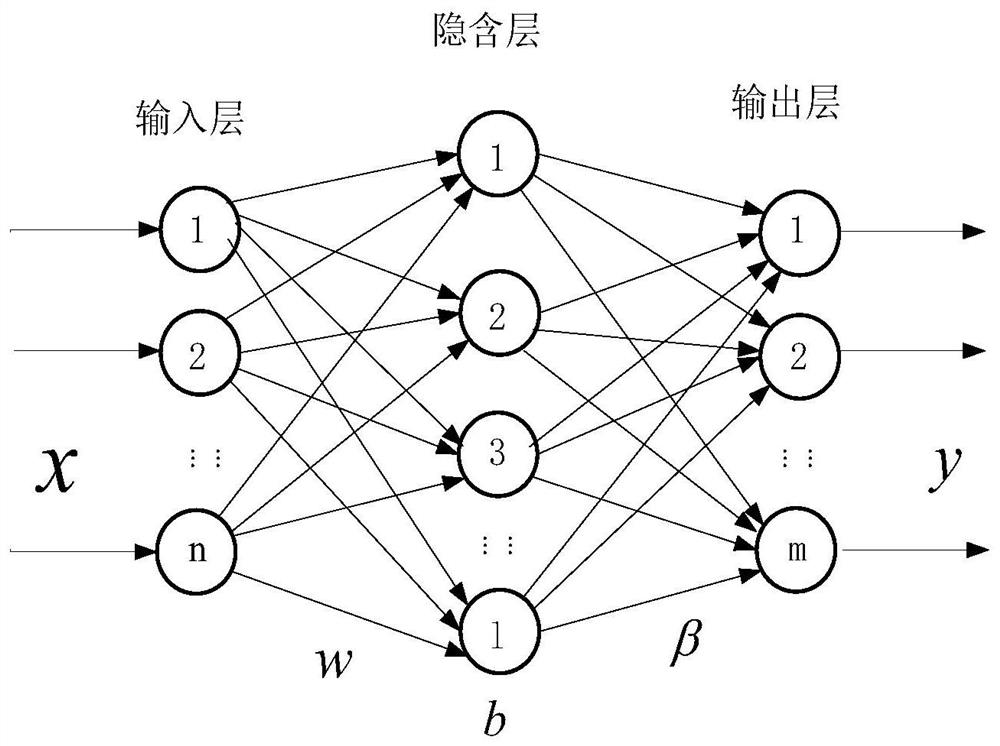

[0131] A mixed model-based soft-sensing method research and a processing method to improve the prediction accuracy of underflow concentration

[0132] Step 1: Mechanistic modeling:

[0133] Step 1.1 Establishment of Mechanism Model:

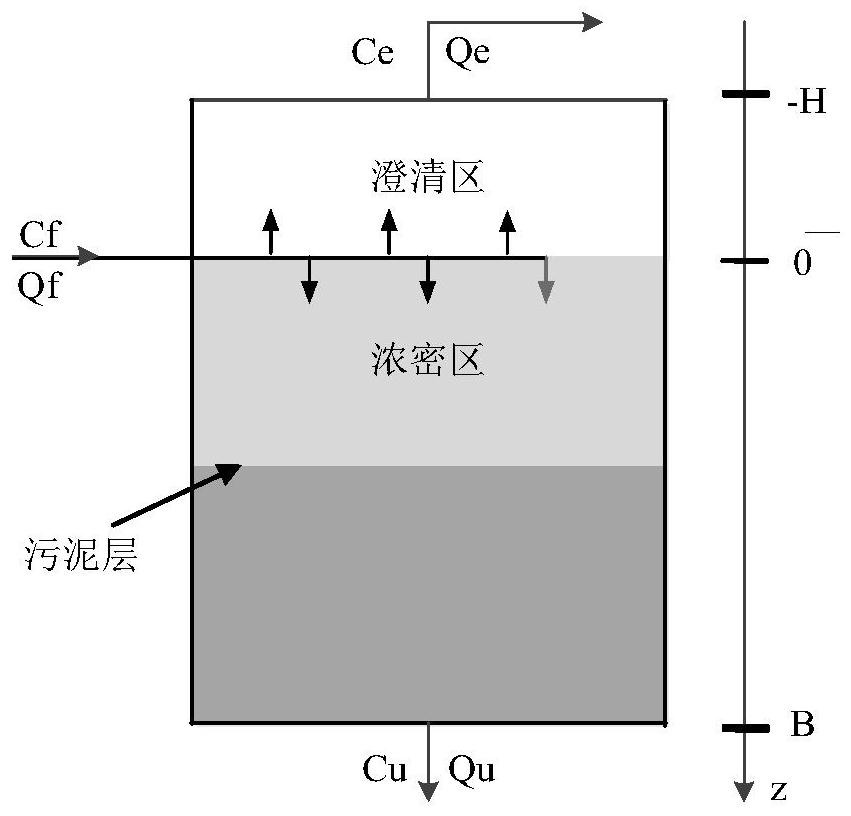

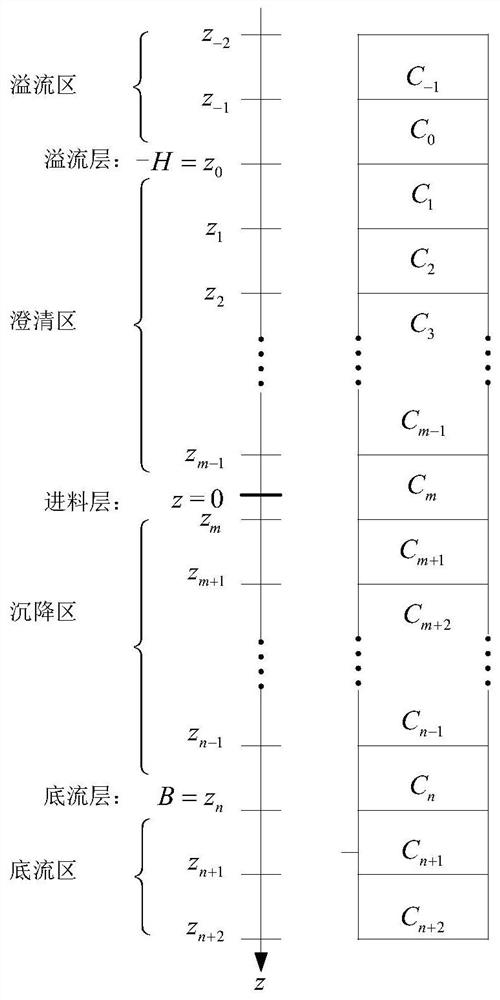

[0134] The thickening process is based on gravity settlement. Obviously, the pulp concentration must depend on the settling time and the space height, so the pulp concentration can be expressed as C(z, t), where the z-axis is the positive direction downward, and t is the dense process time, such as figure 1 shown. We rationalize the assumption that the settlement process is one-dimensional. Since gravity settlement and compression are essentially one-dimensional, the one-dimensional settlement model can capture the basic characteristics of the process well. The mass conservation relationship of the sedimentation process can be described by the partial differential equation of formula (1):

[0135]

[0136] where v s ≥0 is the downward sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com