Laminar metal composite material interface bonding energy calculating method

A technology of interface bonding and composite materials, which is applied in computational theoretical chemistry, instrumentation, informatics, etc., can solve the problem of less interface bonding performance at the microscopic molecular level, and achieve the effect of reducing manufacturing risks and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

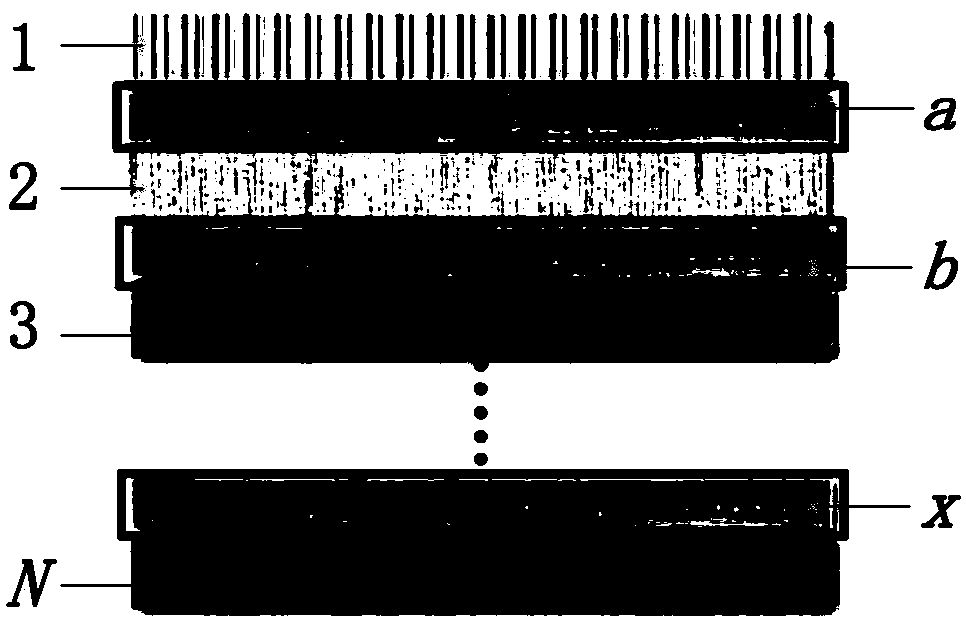

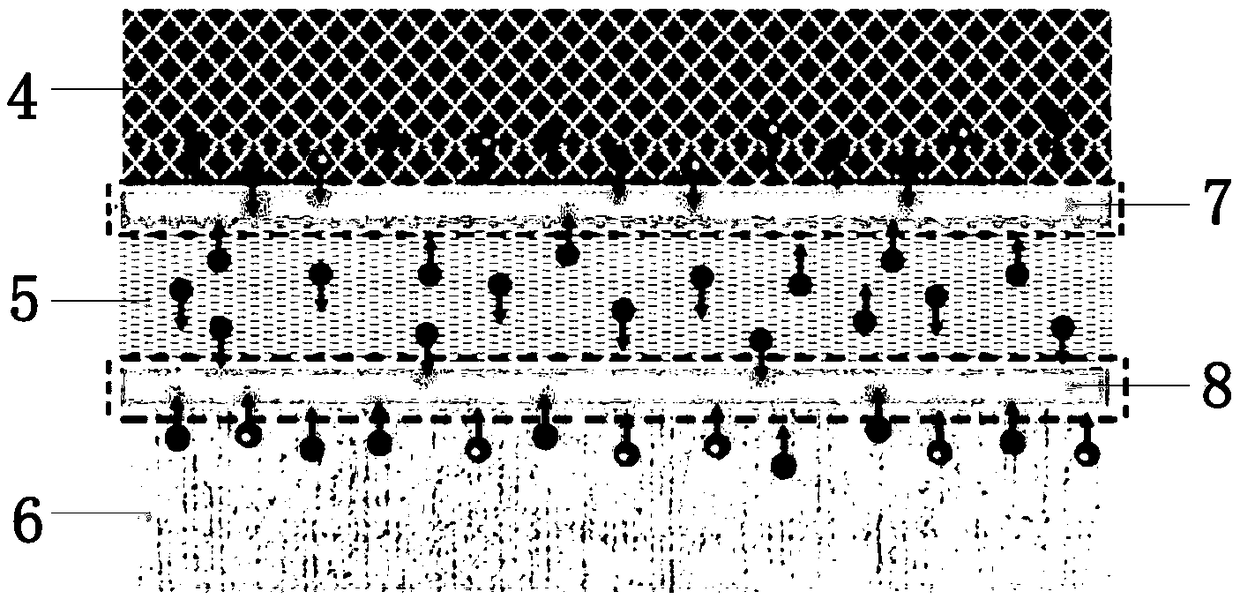

[0040] Taking the oil film bearing tin-based Babbitt alloy ZChSnSb8-4 three-layer structure bushing as an example, the bushing structure from the outside to the inside of each layer of materials is as follows: steel body layer 6, tin-plated layer 5, Babbitt alloy layer 4 , as attached figure 2 shown.

[0041] 1. Build the model in the Visualizer module in the software Materials Studio. When building the model, according to the parameters of the crystal structure, use the Build crystals tool to build the unit cell structure of each layer of material.

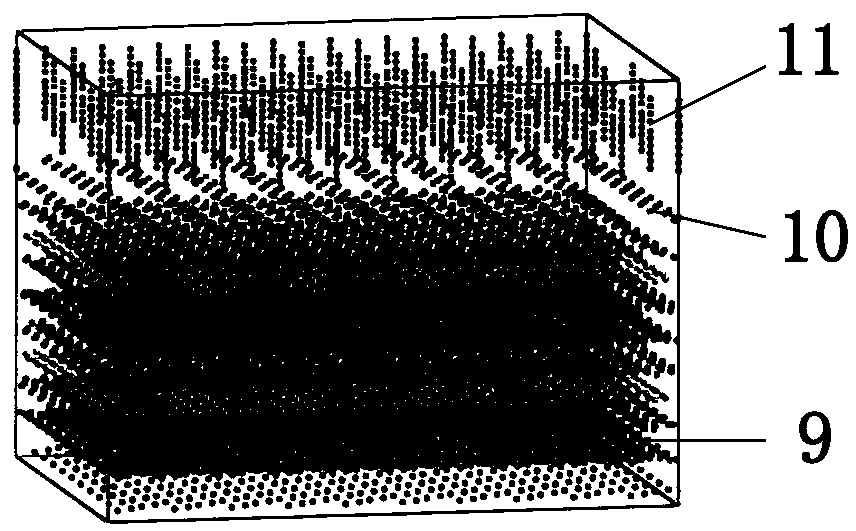

[0042] 2. Use the Cleave Surface tool to perform a simple section on each unit cell, and at the same time expand the unit cell into a certain proportion of supercell. Use the Build Vacuum Slab tool to change the obtained structure from a 2D structure to a 3D structure, and set its vacuum layer thickness. Use the Typing function in the Discover Setup tool to assign a force field to all atoms in the unit cell. After that, Mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com