A phase change thermal control system and method for a high power laser diode pumped source array

A laser diode and thermal control system technology, which is applied in the field of lasers, can solve the problems of short service life and poor reliability of laser diode arrays, and achieve the effect of improving service life and reliability and enhancing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

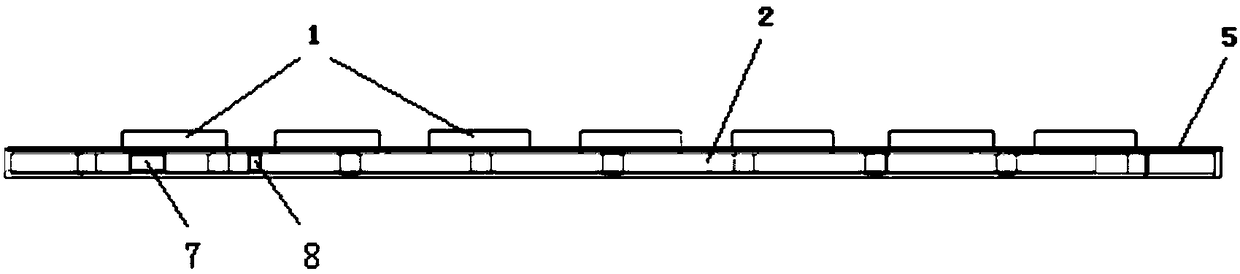

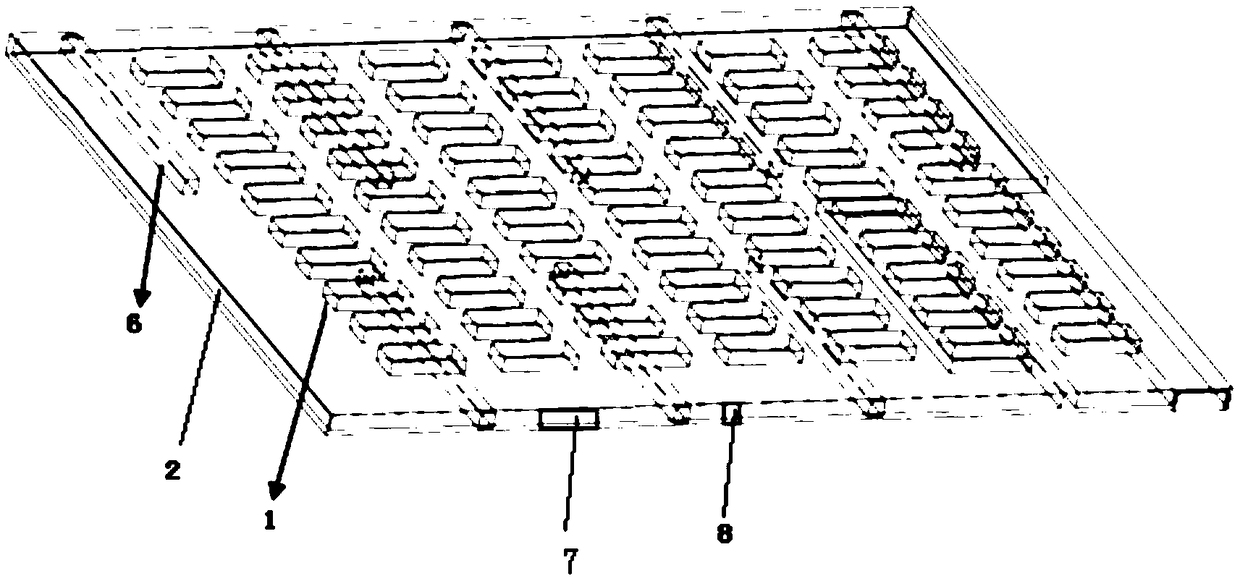

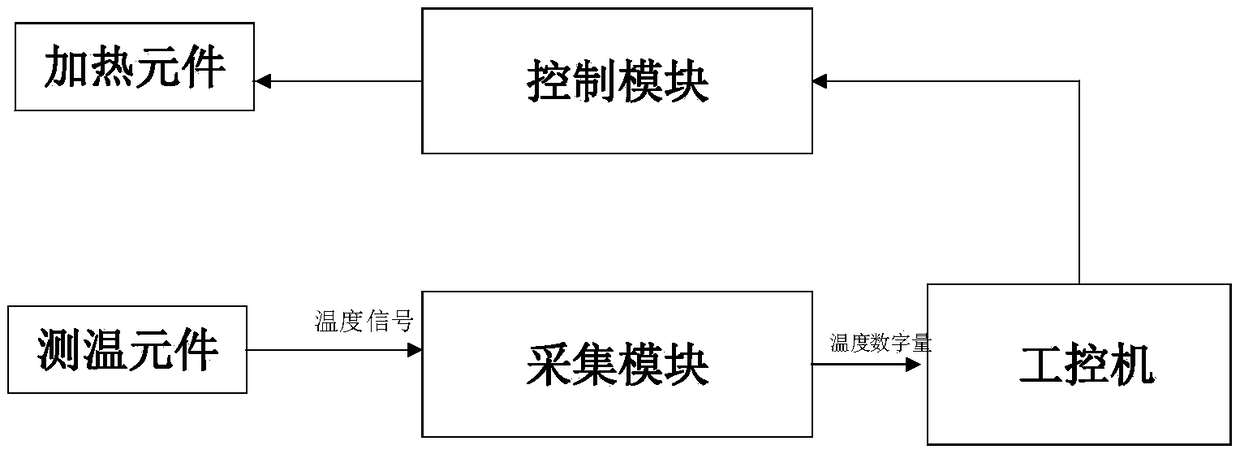

[0039] In the phase-change thermal control system of the present embodiment, the laser diode array is installed on the thermal control system. When the laser diode array works (the laser diode array works in intervals), each laser diode 1 performs electro-optical conversion, and a part of The energy is converted into heat energy, which is transmitted to the packaging shell of the laser diode 1. The purpose of the thermal control system is to dissipate the heat from the large number, high power, and densely distributed laser diode shells, so as to ensure the high reliability of the laser diode 1. , High electro-optical conversion efficiency work.

[0040] Simultaneously the applicant finds in practice, for the laser diode array of high power, sparse array, because heat can form " hot spot " (the position temperature of installing laser diode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com