Method for removing elemental mercury in mercury-containing gas by washing through ultra-fine nano sulfur solution

An ultra-fine nano, gas removal technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low mercury removal efficiency, poor capture capacity, small adsorption capacity, etc., and achieve hydrophilicity. And the effect of good dispersion performance, no secondary pollution, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

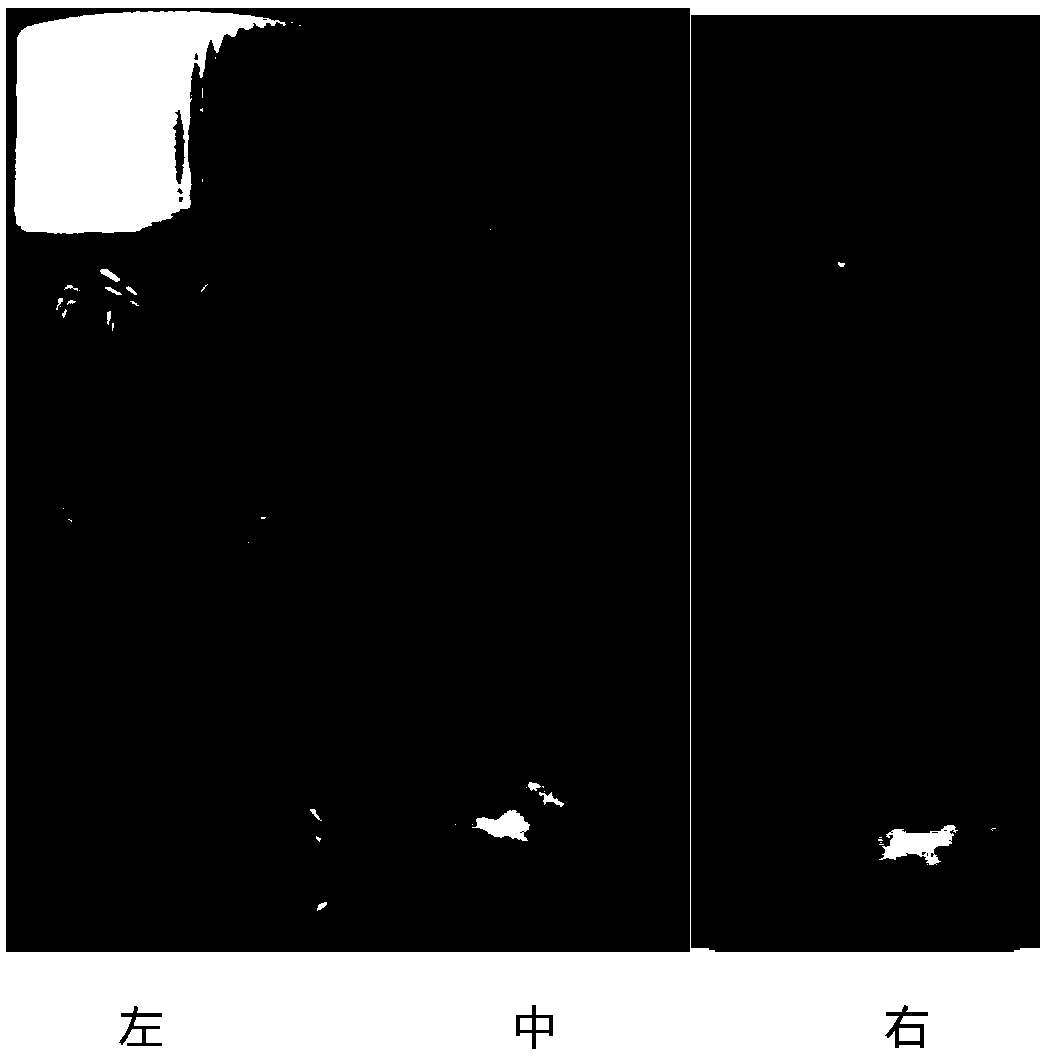

Image

Examples

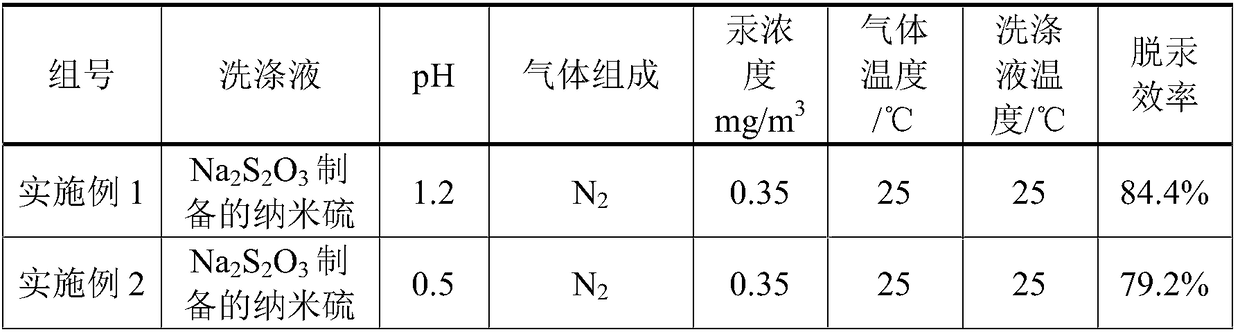

Embodiment 1

[0026] Add 100ml of Na at a concentration of 0.5mol / L at room temperature 2 S 2 o 3 3 ml of saturated sodium dodecylbenzenesulfonate solution was added to the solution as a dispersant, ultrasonically stirred continuously and formic acid was added drop by drop to adjust the pH of the solution to 1.2 to obtain a nano-sulfur colloidal solution. at 0.3m 3 / min gas flow will gas (Hg 0 The concentration is 0.35mg / m 3 , the carrier gas is N 2 ), placed in a bubbling scrubber filled with 75ml ultrafine nano-sulfur solution at room temperature, Hg 0 The removal rate can reach 84.4%.

Embodiment 2

[0028] Add 100ml of Na at a concentration of 0.5mol / L at room temperature 2 S 2 o 3 3 ml of saturated sodium dodecylbenzenesulfonate solution was added to the solution as a dispersant, ultrasonically stirred continuously and concentrated sulfuric acid was added drop by drop to adjust the pH of the solution to 0.5 to obtain a nano-sulfur colloidal solution. at 0.3m 3 / min gas flow will gas (Hg 0 The concentration is 0.35mg / m 3 , the carrier gas is N 2 ), placed in a bubbling scrubber filled with 75ml ultrafine nano-sulfur solution at room temperature, Hg 0 The removal rate can reach 79.2%.

Embodiment 3

[0030] 100ml of 0.5mol / L concentration of NaHSO 3 Under the action of selenium, the solution was heated in a water bath at 100°C for 4 hours, then 3ml of saturated sodium dodecylbenzenesulfonate solution was added as a dispersant, and ultrasonically stirred continuously and formic acid was added drop by drop to adjust the pH of the solution to 1.2 to obtain nano Sulfur colloidal solution. at 0.3m 3 / min gas flow will gas (Hg 0 The concentration is 0.35mg / m 3 , the carrier gas is N 2 ), placed in a bubbling scrubber filled with 75ml ultrafine nano-sulfur solution at room temperature, Hg 0 The removal rate can reach 71.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com