Hole cutting fluid recycling device of digital controlled lathe

A technology of CNC machine tools and recycling devices, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of small contact area between electromagnet and cutting fluid, low removal efficiency, and inability to remove metal impurities. Achieve the effect of solving poor filtering effect, high cleaning efficiency and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

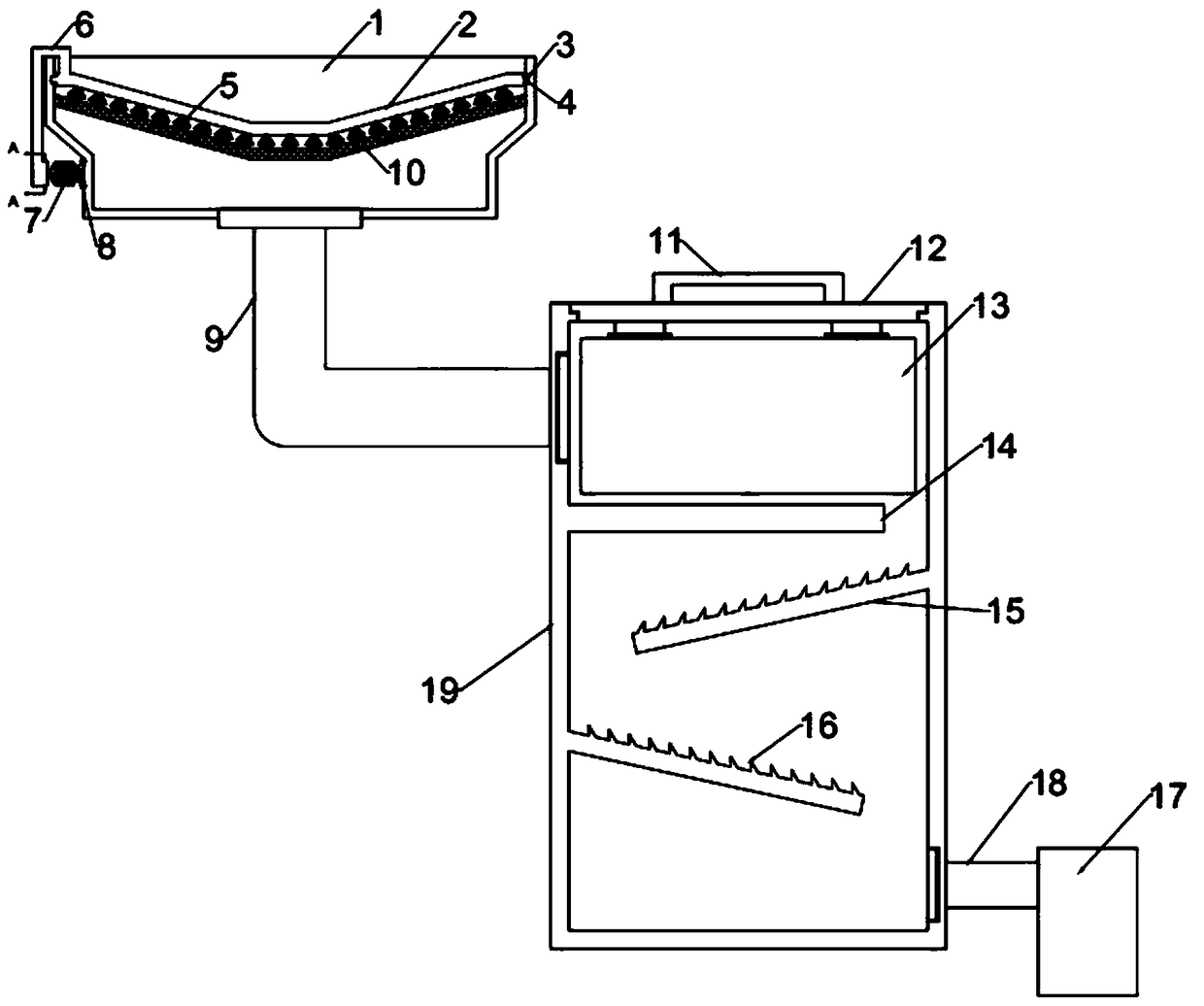

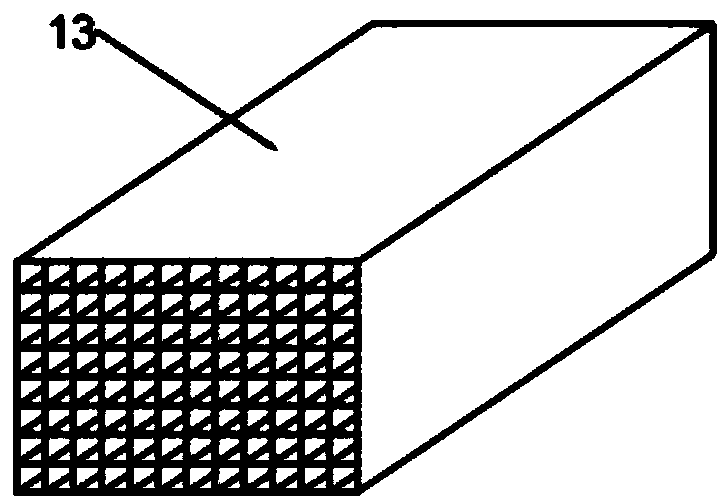

[0022] see Figure 1~3 , in an embodiment of the present invention, a CNC machine tool hole cutting fluid recovery device includes a receiving tray 1, a collection bucket 17 and a purification bucket 19; one side of the purification bucket 19 communicates with the receiving tray 1 through a connecting pipe 9, and the purification bucket The other side of 19 is communicated with collection bucket 17 by conduit 18, and filter screen 10 is installed in the described receiving dish 1, carries out primary filtration by filter screen 10 and then enters purification treatment in purification bucket 19, and described purification bucket 19 is provided with A partition 14, the upper end of the partition 14 is provided with a grid-shaped electromagnet 13, the two ends of the grid-shaped electromagnet 13 are connected and aligned with the water outlet of the connecting pipe 9, and the cutting fluid in the connecting pipe 9 enters In the grid-shaped electromagnet 13, the grid-shaped elect...

Embodiment 2

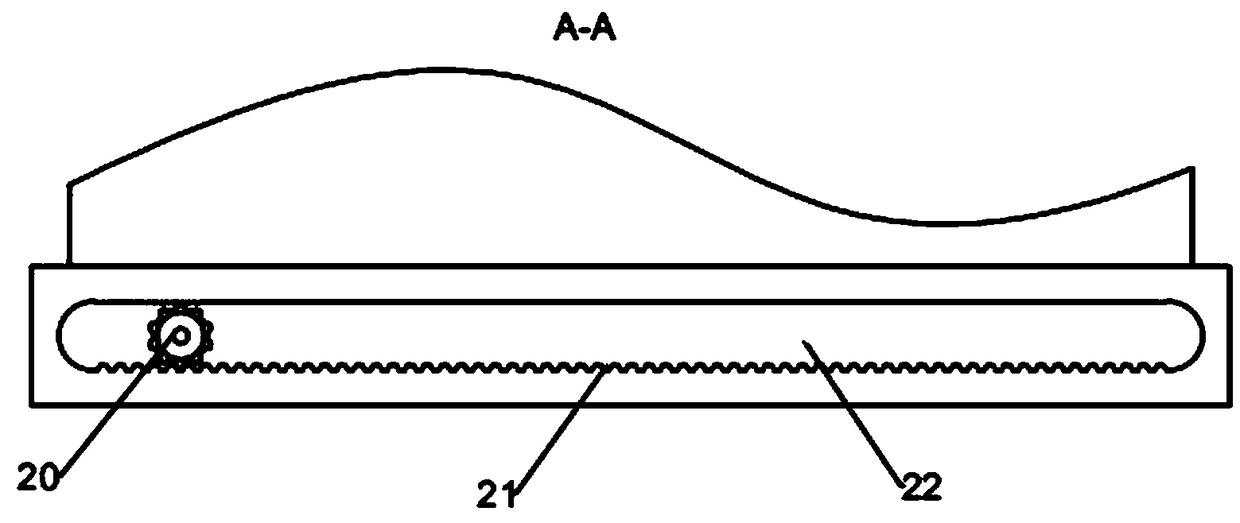

[0025] Since a large amount of metal impurities will be produced when the product is processed by a numerical control machine tool, if a large amount of metal impurities are accumulated on the filter screen 10, the filtering effect of the filter screen 10 will be affected. Therefore, this embodiment is optimized. Specifically, on the filter screen 10 A scrubbing mechanism is provided, and the scrubbing mechanism includes a brush plate 2, a slide bar 6 and a motor 7, and the two ends of the brush plate 2 are fixed with a slider 3, and the slider 3 is slidably installed in the chute 4 arranged on the inner wall of the receiving tray 1, Thus, the sliding connection between the brush plate 2 and the receiving tray 1 is realized.

[0026] Described brush plate 2 is fixedly connected with the bar plate that is provided with bar groove 22 through slide bar 6, and bar groove 22 is provided with bar tooth 21, and bar tooth 21 is fixed on the output shaft of motor 7 The gear 20 meshes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com